loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Application and Advantages of FRP Pultruded Profiles in Modern Construction

Understanding FRP Pultruded Profiles A Sustainable Solution for Modern Engineering

Fiber Reinforced Polymer (FRP) pultruded profiles have emerged as a game changer in various industrial applications owing to their unique properties and advantages. Combining materials like fiberglass with a polymer matrix, FRP pultruded profiles are designed through a continuous manufacturing process known as pultrusion, where fibers are drawn through a resin bath and then pulled through a heated die to form rigid shapes. This innovative technique not only enhances the mechanical properties of the material but also results in products that are lightweight, durable, and corrosion-resistant.

Understanding FRP Pultruded Profiles A Sustainable Solution for Modern Engineering

Corrosion resistance is another critical attribute of FRP pultruded profiles that cannot be overlooked. Unlike metal components that degrade over time when exposed to harsh environmental conditions, FRP materials are inherently resistant to moisture, chemicals, and UV radiation. This quality makes them ideal for use in structures that face challenging conditions, such as bridges, chemical plants, and marine environments. By minimizing maintenance needs and extending the lifespan of the structures, FRP profiles contribute to long-term cost savings.

frp pultruded profiles

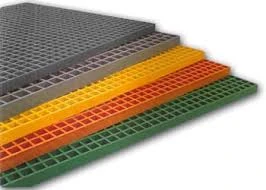

In addition to their durability, FRP pultruded profiles can be customized to meet specific engineering standards. The manufacturing process allows for a variety of shapes, sizes, and colors, enabling engineers to design components that fit particular applications efficiently. Whether it’s an I-beam for structural support or a molded channel for electrical conduits, FRP profiles can be tailored to fulfill diverse requirements across different industries, including construction, automotive, aerospace, and renewable energy.

The sustainability aspect of FRP technology is another reason for its increasing popularity. As the need for eco-friendly materials continues to grow, FRP stands out due to its potential for recyclability and lower environmental impact during production compared to traditional materials. The process of pultrusion generates minimal waste since it is a continuous process with high material utilization efficiency. Additionally, the use of fibers that are both renewable and recyclable aligns with global efforts to reduce the carbon footprint of construction materials.

However, while FRP pultruded profiles offer numerous advantages, they are not without challenges. Understanding the material behavior in specific applications is essential, as factors such as temperature fluctuations and load-bearing capacities can affect performance. Furthermore, the initial costs of FRP materials can be higher than conventional alternatives, although their long-term benefits often outweigh these expenses.

In conclusion, FRP pultruded profiles represent a significant advancement in modern engineering materials, combining lightweight construction, superior durability, and resistance to environmental factors. Their versatility and customization options make them suitable for a wide range of applications, while their lower environmental impact addresses sustainability concerns in today's industry. As technology continues to evolve and more industries recognize the inherent benefits of FRP, it is clear that pultruded profiles will play an increasingly crucial role in the future of engineering and construction.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025