loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Non-slip grating solutions for enhanced safety and traction in various applications

Understanding Anti-Skid Grating Enhancing Safety in Various Environments

Anti-skid grating is a vital safety feature used in diverse environments where slip hazards are prevalent. This specialized type of grating is designed to provide a secure, slip-resistant surface, significantly reducing the risk of accidents due to slip and fall incidents. Its applications span various sectors, including industrial, commercial, marine, and outdoor settings. Understanding its composition, benefits, and uses is crucial for anyone involved in safety management, construction, or facility maintenance.

Composition and Types of Anti-Skid Grating

Anti-skid grating is primarily made from materials such as steel, fiberglass, or aluminum. Each material has distinct advantages, making them suitable for different environments. Steel grating often incorporates a hot-dip galvanization process to enhance corrosion resistance, making it ideal for outdoor industrial applications exposed to harsh weather conditions. On the other hand, fiberglass grating is lightweight, resistant to chemicals, and non-conductive, which makes it perfect for environments handling hazardous materials.

There are various types of anti-skid grating, including bar grating, expanded metal grating, and molded fiberglass grating. Bar grating features perpendicular bars welded together, providing strong load-bearing capabilities. Expanded metal grating, on the other hand, is created by cutting and stretching metal sheets, offering a lighter option while maintaining structural integrity. Molded fiberglass grating comes with a textured surface that provides excellent skid resistance, making it particularly useful in wastewater treatment facilities and chemical processing plants.

Benefits of Using Anti-Skid Grating

The primary benefit of anti-skid grating is safety. Slip and fall accidents can lead to severe injuries and even fatalities, contributing to significant costs for businesses in terms of medical expenses and liability claims. By installing anti-skid grating, facilities can reduce the likelihood of such incidents, promoting a safer working environment.

anti skid grating

Another advantage is durability. Anti-skid grating is designed to withstand heavy loads and extreme environmental conditions. It is resistant to corrosion, impact, and even fire, ensuring a long lifespan under challenging conditions. This durability translates to lower maintenance costs and fewer replacements over time.

Additionally, anti-skid grating comes with a variety of surface textures that enhance grip without compromising aesthetics. Its versatility allows for various applications, ranging from catwalks and walkways to stair treads and platform edges. The textured surfaces provide additional grip even in wet or oily conditions, ensuring safe passage for workers and pedestrians alike.

Applications in Various Environments

Anti-skid grating is widely utilized across many industries. In industrial settings, it is frequently used in manufacturing plants, warehouses, and assembly lines, where workers navigate through busy areas often exposed to spills. In commercial spaces like shopping malls and restaurants, anti-skid grating enhances safety in entryways and outdoor seating areas.

In marine applications, anti-skid grating is essential for docks and ship decks, where water exposure creates slippery conditions. Additionally, outdoor settings like parks and recreational facilities benefit from anti-skid surfaces on walking paths and playgrounds, contributing to public safety.

Conclusion

In conclusion, anti-skid grating is an indispensable safety feature across various industries and environments. Its ability to provide a secure, slip-resistant surface enhances safety, reduces liability risks, and fosters confidence among workers and the public. With a range of materials and designs available, businesses can select the right type of anti-skid grating tailored to their specific needs, ensuring a safer, more productive environment. Investing in this crucial safety measure is not just a regulatory requirement but a fundamental aspect of responsible facility management.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

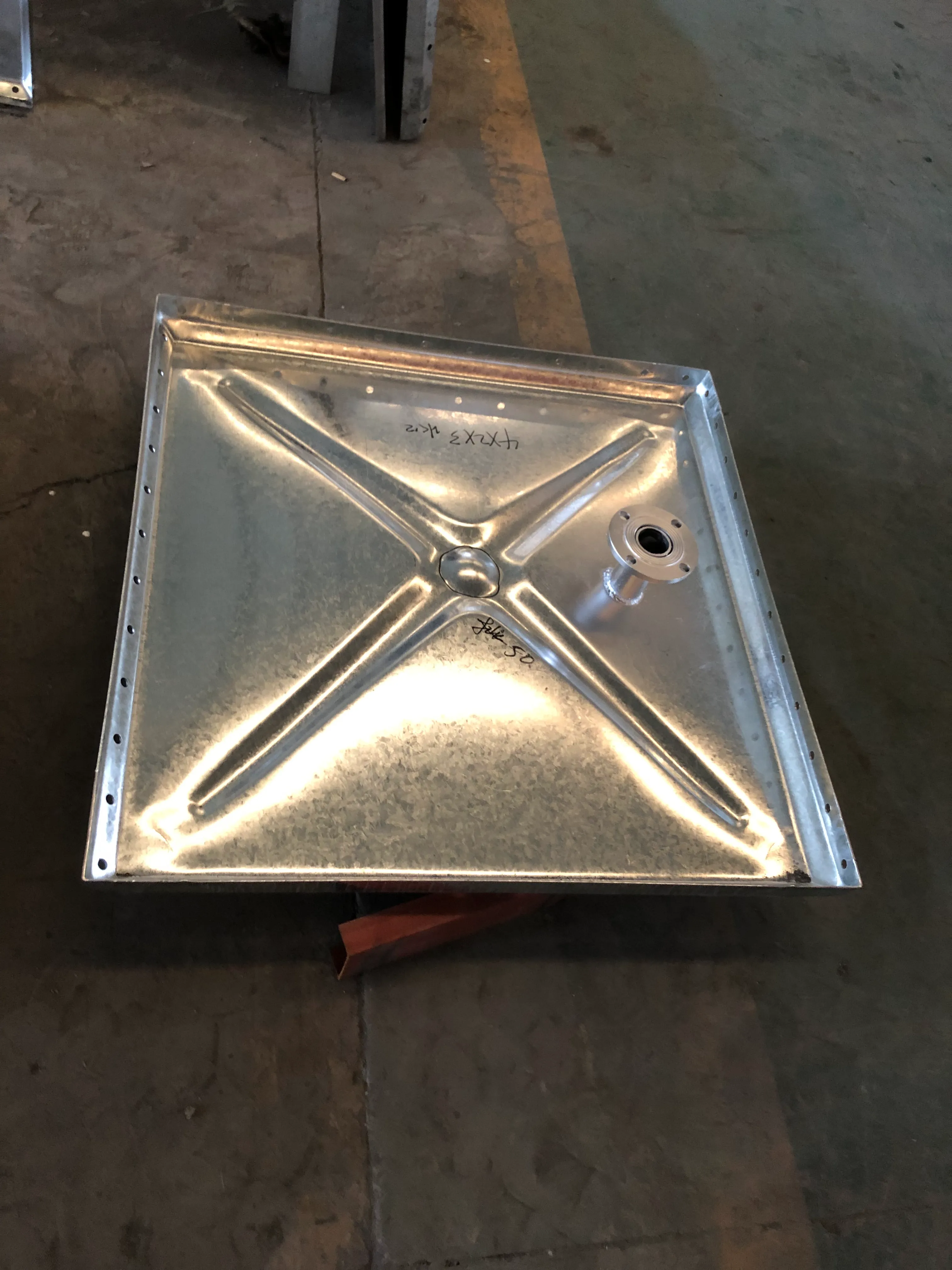

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025