loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

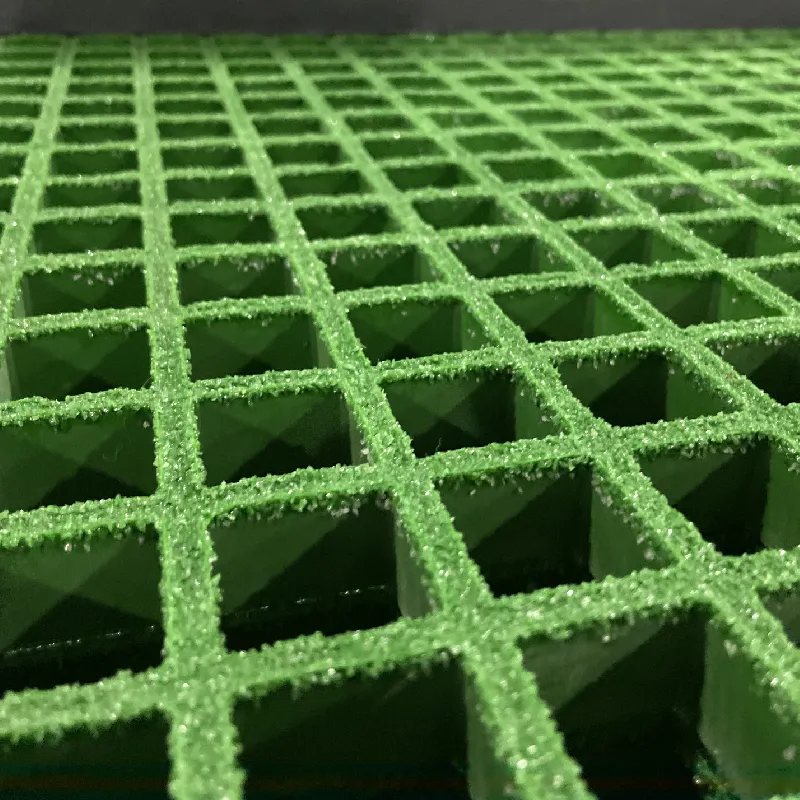

anti skid grating

Understanding Anti-Skid Grating An Essential Safety Feature

In various industrial, commercial, and residential settings, safety is a paramount concern. One of the critical elements in ensuring safety, particularly in environments prone to slippery conditions, is the use of anti-skid grating. This specialized product is designed to provide a secure footing for individuals while minimizing the risk of accidents due to slips and falls. In this article, we will explore what anti-skid grating is, its applications, materials, and the importance of incorporating it into safety protocols.

What Is Anti-Skid Grating?

Anti-skid grating, also referred to as slip-resistant grating, is a type of flooring used in areas where there's a likelihood of water, oil, grease, or other slippery substances. Made from various materials, this grating features a textured surface or coatings that enhance grip. The design often includes raised patterns or slip-resistant inserts that effectively increase traction, making it ideal for high-traffic areas.

Applications of Anti-Skid Grating

The applications of anti-skid grating are vast. It is commonly used in industrial settings, such as factories, warehouses, power plants, and aircraft hangars, where processes may involve spills or wet conditions. Moreover, anti-skid grating is beneficial in outdoor environments like stairways, walkways, and ramps, where rain or snow can create hazardous surfaces.

In addition to industrial applications, anti-skid grating can be found in commercial establishments such as shopping malls, restaurants, and educational institutions. Even in residential projects, homeowners increasingly recognize the importance of installing this type of grating around swimming pools, patios, and garages to ensure safety for family and guests.

Materials Used in Anti-Skid Grating

anti skid grating

Anti-skid grating is manufactured from several materials, including steel, aluminum, and fiberglass-reinforced polymer (FRP). Each of these materials has unique properties that make them suitable for different environments.

1. Steel Grating Known for its strength and durability, steel grating is ideal for heavy-duty applications. It can support substantial loads, making it suitable for industrial facilities. However, it may corrode if not appropriately treated.

2. Aluminum Grating Lightweight and resistant to corrosion, aluminum grating is often used in environments that require frequent cleaning, such as food processing facilities. Its non-slip surface is effective in maintaining safety standards.

3. FRP Grating Fiberglass-reinforced polymer grating offers excellent slip resistance and is non-corrosive, making it suitable for harsh chemical environments. It is also lightweight and easy to install, leading to lower labor costs.

Importance of Anti-Skid Grating in Safety Protocols

Incorporating anti-skid grating into safety protocols is vital for reducing workplace injuries and ensuring compliance with regulations. Slips and falls are among the leading causes of accidents in various settings, often resulting in serious injuries or costly legal claims. By investing in anti-skid solutions, organizations can demonstrate a commitment to safety, protect their employees and visitors, and potentially lower insurance premiums.

Moreover, choosing the right anti-skid grating can lead to enhanced productivity. Employees who feel safe in their environment are likely to be more focused and efficient. Additionally, customers appreciate the attention to safety, which can enhance their perception of a business.

In conclusion, anti-skid grating plays a crucial role in promoting safety across various sectors. By understanding its applications, materials, and importance, decision-makers can make informed choices that prioritize the well-being of everyone in their facilities. As safety continues to be a top priority, integrating anti-skid grating into design and construction will remain essential for preventing slips and falls.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025