loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advanced Filtration Solutions for Industrial Water Treatment Systems

The Importance of Industrial Water Filter Systems

In today's industrial landscape, the efficient use and management of water resources have become crucial due to increasing environmental regulations, rising operational costs, and the need for sustainable practices. One of the most effective ways to ensure the quality of water used in industrial processes is through the implementation of industrial water filter systems. These systems not only improve the quality of water but also enhance operational efficiency and reduce waste.

Understanding Industrial Water Filter Systems

Industrial water filter systems are designed to remove contaminants from water used in various industrial applications. These systems can vary widely in complexity and technology, depending on the specific requirements of the industry. Common types of filtration methods include mechanical filtration, activated carbon filtration, reverse osmosis, and ultraviolet (UV) disinfection. Each method has its unique advantages and is suited to different types of contaminants.

For instance, mechanical filters can effectively remove larger particles and sediments, while activated carbon filters are excellent for eliminating organic compounds and odors. Reverse osmosis systems are capable of removing dissolved solids, making them perfect for industries requiring high-purity water, such as pharmaceuticals and electronics. UV disinfection systems, on the other hand, are effective in killing bacteria and viruses, ensuring that the water is safe for use.

Benefits of Using Industrial Water Filter Systems

1. Enhanced Water Quality One of the most significant advantages of employing water filter systems is the improvement in water quality. Contaminated water can lead to equipment corrosion, product contamination, and substandard output. By using effective filtration systems, industries can ensure that their water meets the required quality standards, thus maintaining product integrity.

industrial water filter system

2. Cost Efficiency While the initial investment in industrial water filter systems may be substantial, they can lead to significant cost savings in the long run. Clean water can reduce maintenance costs related to equipment damage and prolong the lifespan of machinery. Moreover, high-quality water often results in fewer production issues, reducing downtime and increasing overall productivity.

3. Environmental Compliance As regulatory standards for water use become stricter, industries are required to ensure that they are compliant with environmental regulations. Industrial water filter systems help businesses meet these regulations by effectively treating wastewater and reducing pollutants before discharge, thus minimizing environmental impact.

4. Sustainability Implementing water filtration systems is a critical step towards sustainable industrial practices. By filtering and reusing water, industries can significantly reduce their freshwater consumption and waste production. This not only conserves a vital resource but also enhances the organization's image as an environmentally responsible entity.

5. Customization Water filter systems can be customized to meet the specific needs of different industries. Whether it is food and beverage, pharmaceuticals, or manufacturing, each sector has unique water quality requirements, and advanced filtration systems can be tailored to address these needs appropriately.

Conclusion

In conclusion, industrial water filter systems are a cornerstone of modern industrial operations. They offer a plethora of benefits, including improved water quality, cost savings, compliance with environmental standards, and contributions to sustainability. As industries strive to optimize their water use and reduce their environmental footprint, investing in advanced filtration technology is not just a choice but a necessity. By embracing these systems, industries can ensure their processes are efficient, sustainable, and compliant, paving the way for a more sustainable future.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

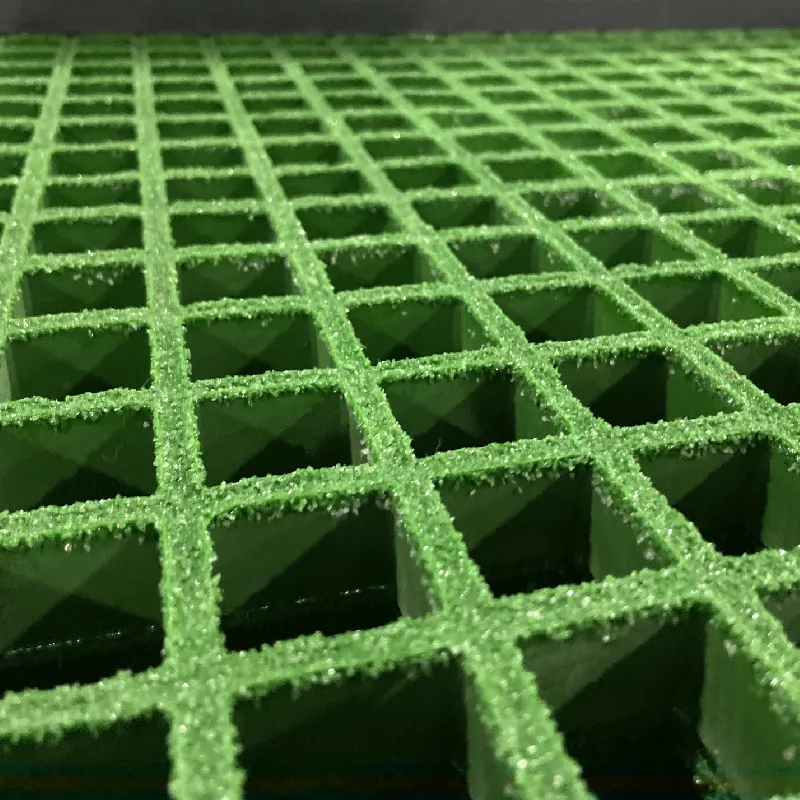

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025