loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

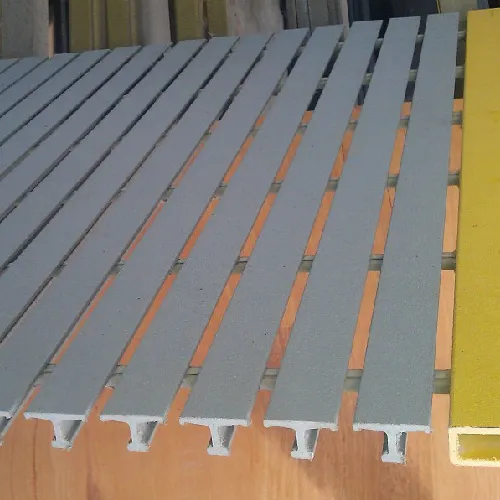

4 x8 fiberglass grating

The Benefits and Applications of 4% x 8% Fiberglass Grating

Fiberglass grating has emerged as a versatile and robust solution for various industrial and commercial applications. Among the many options available in the market, the 4% x 8% fiberglass grating stands out due to its unique properties and advantages. This article explores the benefits, applications, and reasons for choosing this specific type of fiberglass grating.

What is Fiberglass Grating?

Fiberglass grating is a composite material made from fiberglass reinforced plastic (FRP). It consists of a grid of interlocking bars that provide strength while being lightweight. The structure is manufactured using a pultrusion process, which ensures uniformity and high structural integrity. Fiberglass grating is available in various sizes, thicknesses, and load capacities, making it suitable for a multitude of applications.

Advantages of 4% x 8% Fiberglass Grating

1. Corrosion Resistance One of the most prominent advantages of fiberglass grating is its resistance to corrosion. Unlike traditional materials like steel, fiberglass does not rust or degrade when exposed to harsh chemicals, water, or moisture. This property makes it an ideal choice for applications in corrosive environments such as chemical plants, waste treatment facilities, and marine environments.

2. Lightweight and Strong The 4% x 8% fiberglass grating offers an excellent strength-to-weight ratio. Its lightweight nature simplifies installation and reduces labor costs. Despite being lightweight, this grating is incredibly strong, capable of supporting heavy loads without compromising structural integrity.

3. Safety Features Safety is a paramount concern in industrial settings. The surfaces of fiberglass grating can be designed to be slip-resistant, which reduces the risk of accidents and injuries. This feature is particularly beneficial in wet or oily environments where slips and falls are common.

4. Low Maintenance Unlike materials that require regular maintenance and painting, fiberglass grating is virtually maintenance-free. Its inherent resistance to environmental factors means it does not need to be treated or painted over time, leading to significant savings in maintenance costs.

4 x8 fiberglass grating

5. Customizable Designs The 4% x 8% specification allows for flexibility in design and applications. Customers can choose the spacing, thickness, and color to suit their specific needs. This customization is critical in industries where aesthetics and functionality must align.

Applications of 4% x 8% Fiberglass Grating

The versatility of 4% x 8% fiberglass grating makes it applicable in various sectors

- Industrial Flooring It is commonly used as flooring in factories, plants, and assembly lines where durability and safety are essential. - Walkways and Platforms It serves as walkways and platforms in areas requiring safe access above ground level, such as maintenance platforms or catwalks around machinery.

- Water Treatment Plants With its corrosion resistance, fiberglass grating is prevalent in water treatment applications, offering a safe and durable surface for employees.

- Marine Applications Due to its lightweight nature and resistance to water saturation, 4% x 8% fiberglass grating is a preferred choice for docks, piers, and other marine structures.

- Chemical Processing Facilities Many chemical processing facilities utilize fiberglass grating to create safe working areas that resist the dangers of chemical spills.

Conclusion

4% x 8% fiberglass grating is a valuable asset in numerous industries due to its unique combination of strength, durability, and resistance to environmental challenges. With its many advantages, including corrosion resistance, low maintenance, and safety features, it is becoming the go-to choice for construction and engineering professionals. As industries continue to seek innovative solutions to meet operational challenges, the use of fiberglass grating will undoubtedly grow, showcasing the material's central role in modern infrastructure.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025