loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

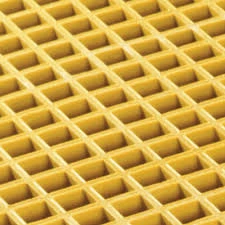

Durable 4% 20 x 8 Fiberglass Grating for Industrial Applications and Flooring Solutions

Understanding 4% x 8% Fiberglass Grating Benefits and Applications

In various industrial and commercial settings, the demand for durable and reliable flooring solutions is paramount. One such solution that has gained considerable attention is fiberglass grating, particularly the 4% x 8% variant. This innovative material offers a unique blend of strength, versatility, and low maintenance, making it an ideal choice for various applications. In this article, we will explore the characteristics, benefits, and common applications of 4% x 8% fiberglass grating.

What is Fiberglass Grating?

Fiberglass grating is a composite material made from a combination of glass fibers, resin, and a variety of fillers. The result is a lightweight yet robust grating product that provides excellent load-bearing capabilities. The term 4% x 8% typically refers to the dimensions of the grating panels, with 4% representing the thickness of the grating and 8% specifying the width. This type of fiberglass grating is engineered for specific applications, where strength, corrosion resistance, and a non-slip surface are critical.

Key Benefits of 4% x 8% Fiberglass Grating

1. Corrosion Resistance One of the primary advantages of fiberglass grating is its exceptional resistance to a range of chemicals and environmental factors. Unlike traditional metal grating, fiberglass will not rust or corrode, making it suitable for environments exposed to harsh chemicals or marine settings. This greatly increases the lifespan of the product, reducing the need for frequent replacements.

2. Lightweight Design Fiberglass grating is significantly lighter than metal alternatives, making it easier to transport and install. This weight efficiency can lead to reduced labor costs and lower structural load concerns, allowing for greater design flexibility in various projects.

3. Load-Bearing Capability Despite its lightweight nature, 4% x 8% fiberglass grating can support substantial loads. Its strength allows it to be used in applications requiring heavy-duty flooring solutions, such as industrial walkways, platforms, and machinery supports.

4. Safety Features The non-slip surface of fiberglass grating enhances safety in environments where slips and falls could pose risks. This feature is particularly important in wet or oily conditions common in industrial settings, making fiberglass grating a preferred choice for safety-conscious applications.

5. Maintenance-Free Fiberglass grating requires minimal upkeep. It does not need to be painted, treated, or sealed, which translates to lower maintenance costs and time savings for facility managers.

4 x8 fiberglass grating

6. Versatility 4% x 8% fiberglass grating can be tailored to serve a variety of applications. It can be molded into different shapes and sizes, allowing for customization based on specific project needs.

Common Applications

The versatility of 4% x 8% fiberglass grating means it can be found in an array of industries and applications, including

- Wastewater Treatment Facilities Due to its corrosion resistance and non-slip surface, fiberglass grating is often used in tanks, walkways, and access platforms in wastewater treatment plants.

- Chemical Plants The ability to withstand corrosive chemicals makes fiberglass grating a perfect fit for chemical processing facilities, where safety and durability are paramount.

- Marine Applications The lightweight and rustproof properties of fiberglass grating make it ideal for use in docks, piers, and marinas, where exposure to water and chemicals is a constant concern.

- Food Processing Facilities The non-porous surface of fiberglass grating helps maintain hygiene standards, making it suitable for food processing and handling areas.

Conclusion

4% x 8% fiberglass grating stands out as a versatile, durable, and low-maintenance solution for various industrial and commercial applications. Its unique properties, such as corrosion resistance, lightweight design, and safety features, make it an indispensable choice for facilities looking to enhance operational efficiency while ensuring worker safety. As industries continue to evolve and seek innovative materials, fiberglass grating is poised to play a significant role in sustainable and effective design practices. Whether for new construction or renovation projects, the advantages of 4% x 8% fiberglass grating cannot be overstated, making it a worthy investment for any facility.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025