loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

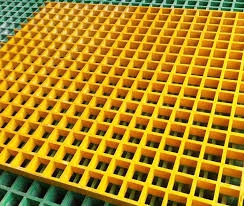

25mm grp grating

Understanding 25mm GRP Grating An Overview

Grating is an essential component in various industries, providing safety, strength, and enhanced functionality. Among the different types of gratings available, the 25mm Glass Reinforced Plastic (GRP) grating stands out for its distinctive properties and versatility. This article delves into the characteristics, advantages, applications, and maintenance of 25mm GRP grating.

What is GRP Grating?

GRP grating is a composite material made from a combination of glass fibers and resin, resulting in a lightweight yet extremely strong construction. The manufacturing process involves layering glass fibers within a resin matrix, which is then cured to form a solid structure. One of the standout features of 25mm GRP grating is its thickness; measuring 25mm, it provides robust support and durability, making it suitable for various environments and applications.

Key Characteristics of 25mm GRP Grating

1. High Load-Bearing Capacity The thickness of 25mm plays a crucial role in the load-bearing capacity of the grating. It is designed to handle significant weight while minimizing the risk of deflection and breakage.

2. Corrosion Resistance GRP grating is inherently resistant to corrosive substances, which makes it an excellent choice for industrial applications, especially in chemical manufacturing plants, wastewater treatment facilities, and marine environments.

3. Lightweight Despite its strength, 25mm GRP grating is lightweight, making it easy to handle and install. This feature reduces transportation costs and simplifies installation processes.

4. Anti-Slip Surface Safety is a primary concern in industrial settings, and the anti-slip surface of GRP grating provides excellent traction for personnel, reducing the risk of slips and falls.

5. Low Maintenance GRP grating requires minimal maintenance compared to traditional materials like steel. Its resistance to rust, rot, and chemical damage ensures longevity and reduces the need for frequent repairs or replacements.

Advantages of 25mm GRP Grating

25mm grp grating

1. Cost Effectiveness While the initial investment in GRP grating may be higher than other materials, its durability and low maintenance costs result in long-term savings.

2. Versatility The applications of 25mm GRP grating are vast. It can be used for platforms, walkways, stair treads, and even drainage covers. The versatility of this material allows it to be customized for specific industrial needs.

3. Environmental Impact Being a composite material, GRP is often seen as a more environmentally friendly alternative compared to metal, as it can be recycled and has a lower overall carbon footprint during production.

4. Ease of Fabrication 25mm GRP grating can be easily cut and fabricated to fit specific dimensions, providing tailored solutions for unique projects.

Applications of 25mm GRP Grating

The applications of 25mm GRP grating span multiple industries

- Chemical Industry Its resistance to corrosive chemicals makes it an ideal choice for flooring and walkways. - Oil and Gas Sector Used in offshore platforms and refineries due to its durability and resistance to saline environments. - Construction Frequently utilized in building site walkways and scaffolding. - Wastewater Treatment The non-corrosive nature of GRP makes it suitable for environments that deal with sewage and chemicals.

Maintenance and Care

Maintaining 25mm GRP grating is relatively straightforward. Regular cleaning with water and mild detergents will prevent the buildup of dirt and grime. It's advisable to conduct periodic inspections to ensure the integrity of the grating and promptly address any signs of wear or damage.

Conclusion

In summary, 25mm GRP grating offers an optimal combination of strength, durability, and safety for a wide range of applications. With its unique properties, it addresses the needs of various industries looking for reliable and efficient grating solutions. As industries continue to evolve, the demand for materials like 25mm GRP grating is likely to grow, reinforcing its position as a valuable asset in industrial settings. Whether you're in construction, chemical processing, or maintenance, incorporating 25mm GRP grating can enhance safety and effectiveness in your operations.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025