loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

24 x 72 frp vessel

Understanding 24% 20 x 72 FRP Vessels Applications, Advantages, and Considerations

In modern engineering, the need for robust and efficient storage solutions has led to the widespread use of specialized vessels. One such example is the 24% 20 x 72 FRP (Fiber Reinforced Polymer) vessel. This article will delve into the characteristics, applications, benefits, and considerations associated with these vessels, to provide a comprehensive understanding of why they are a preferred choice in various industries.

What is an FRP Vessel?

FRP vessels are made from a composite material that includes a polymer matrix reinforced with fibers, typically glass or carbon. This combination results in a material that boasts a high strength-to-weight ratio, making it ideal for various applications, particularly in scenarios where corrosion resistance is paramount. The designation 24% 20 x 72 refers to specific dimensions and characteristics of the vessel, where 24% likely indicates the concentration of a substance that the vessel is designed to store or process, while 20 x 72 refers to the vessel's dimensions, typically in inches.

Applications of 24% FRP Vessels

1. Chemical Storage FRP vessels are widely utilized in the chemical industry for the storage of corrosive materials. The 24% concentration indicates that the vessel is well-suited for chemicals that require a specific concentration for safe handling and processing. Industries often rely on these vessels to safely store acids, alkalis, and other aggressive chemical solutions that could otherwise damage conventional metal tanks.

2. Water Treatment In water treatment facilities, FRP vessels are employed for various processes, including filtration and chemical dosing. Their resistance to corrosion means they can handle chlorine and other harsh chemicals used in water purification processes without deteriorating, ensuring longevity and reliability in critical infrastructure.

3. Food and Beverage Industry In the food sector, the use of FRP vessels is prevalent for storing and processing ingredients that require stringent hygiene standards. The material is non-reactive, ensuring that the stored substances maintain their integrity. For example, these vessels can be used for fermenting or storing various food products without the risk of contamination.

4. Pharmaceutical Production The pharmaceutical industry also makes use of FRP vessels for the storage of APIs (Active Pharmaceutical Ingredients) and other chemical compounds. The inert nature of FRP materials aligns with the industry’s stringent requirements for contamination-free environments.

Advantages of FRP Vessels

1. Corrosion Resistance One of the most significant advantages of FRP vessels is their resistance to corrosion. Unlike traditional steel tanks, which can corrode over time when exposed to harsh environments, FRP containers maintain their integrity, leading to lower maintenance costs and a longer service life.

24 x 72 frp vessel

2. Lightweight FRP vessels are considerably lighter than their metal counterparts, making them easier to install and transport. This characteristic is particularly beneficial in facilities where space is limited or where heavy equipment can create logistical challenges.

3. Customization FRP technology allows for a high degree of customization in terms of design, size, and color. This flexibility enables manufacturers to create vessels tailored to specific requirements, including unique shapes or volumetric capacities.

4. Thermal Insulation FRP materials offer excellent thermal insulation properties, which can be advantageous in applications where temperature control is crucial.

Considerations When Using FRP Vessels

While FRP vessels have numerous benefits, several factors should be considered

1. Thermal Limitations FRP materials can have limitations regarding high temperatures. It is essential to ensure that the application does not expose the vessel to conditions beyond recommended thermal thresholds.

2. Impact Resistance While FRP is highly durable, it can be more susceptible to impact damage compared to metals. Any physical impacts should be managed accordingly during handling and installation.

3. Cost The initial cost of FRP vessels can be higher than that of traditional materials. However, when considering longevity and maintenance savings, they can be economically advantageous in the long run.

Conclusion

24% 20 x 72 FRP vessels represent a pivotal advancement in storage technology, blending strength, lightness, and resistance to corrosion. Their applications range from chemical storage to food processing and pharmaceuticals, making them essential across various industries. By understanding their advantages and considerations, businesses can make informed decisions that enhance operational efficiency while ensuring safety and compliance in their practices. The ongoing development in FRP manufacturing continues to open new avenues for innovation, keeping these vessels at the forefront of industrial solutions.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

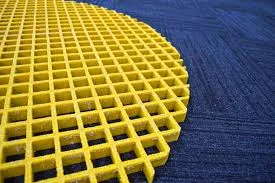

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025