loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

24 x 72 frp vessel

The Importance of 24% FRP Vessels in Industrial Applications

In today's rapidly advancing industrial landscape, the demand for durable and efficient storage solutions has become paramount. One such solution is the 24% FRP (Fiberglass Reinforced Plastic) vessel, which is gaining traction across multiple sectors due to its unique properties and advantages. FRP vessels are recognized for their exceptional mechanical strength, corrosion resistance, and lightweight nature, making them ideal for a variety of applications.

The Importance of 24% FRP Vessels in Industrial Applications

One of the most important features of 24% FRP vessels is their outstanding resistance to corrosion. In many industrial environments, storage tanks must contend with aggressive chemicals and harsh operating conditions. Traditional materials often succumb to corrosion, leading to leaks, product contamination, and costly downtime. However, 24% FRP vessels are designed to withstand a wide variety of chemicals, making them a reliable choice for storing corrosive substances. This resistance not only extends the lifespan of the vessel but also reduces maintenance costs and enhances safety by minimizing the risk of failures that can result in hazardous situations.

24 x 72 frp vessel

The versatility of 24% FRP vessels extends to their application in numerous industries, including chemical processing, water treatment, food and beverage, and pharmaceuticals. In the chemical industry, for example, these vessels are employed to store caustic solutions and other reactive materials, effectively minimizing the risk associated with chemical handling. In water treatment facilities, FRP tanks are commonly used for chemical storage as well as for various processes including filtration and disinfection.

Moreover, the use of FRP vessels contributes to sustainability efforts. Their lighter weight reduces carbon emissions associated with transportation, while their durability means that fewer replacements are needed over time, thereby decreasing waste. Additionally, many manufacturers are now implementing eco-friendly production processes for FRP materials, further enhancing their appeal as a sustainable solution.

In conclusion, the 24% FRP vessel is an exemplary solution for modern industrial storage needs, combining strength, safety, and sustainability. As industries continue to seek innovative ways to meet operational challenges while adhering to environmental regulations, the adoption of FRP technology is likely to grow. Investing in 24% FRP vessels not only ensures reliable performance and safety in challenging environments but also positions businesses favorably as leaders in their respective fields, demonstrating a commitment to utilizing advanced materials for a sustainable future.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

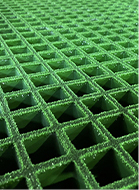

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025