loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Design of a 2472 FRP Vessel for Enhanced Performance and Durability

Understanding the 2472 FRP Vessel Innovations in Composite Engineering

In recent years, the advancements in material science have led to the development of innovative composite materials that are revolutionizing various industries. One such innovation is the FRP (Fiber Reinforced Plastic) vessel, exemplified by the 2472 model. This article explores the significance, features, and applications of the 2472 FRP vessel, highlighting its role in modern engineering.

What is an FRP Vessel?

Fiber Reinforced Plastic (FRP) vessels are composite structures made from a polymer matrix reinforced with fibers, typically glass or carbon. The combination of these materials results in a product that is both lightweight and incredibly strong, making it ideal for a variety of applications. The 2472 FRP vessel is a notable example, pushing the boundaries of what can be achieved with composite materials.

Key Features of the 2472 FRP Vessel

1. High Strength-to-Weight Ratio One of the most remarkable features of the 2472 FRP vessel is its high strength-to-weight ratio. This property allows for the construction of larger and more durable structures without the significant weight associated with traditional materials like steel or aluminum.

2. Corrosion Resistance Unlike metal vessels, the 2472 FRP vessel is resistant to a wide range of corrosive substances. This characteristic makes it particularly valuable in chemical processing, maritime, and waste management applications where exposure to harsh chemicals is commonplace.

3. Thermal Insulation FRP materials inherently provide excellent thermal insulation. This means that vessels constructed from this material can maintain temperature more effectively, which is particularly beneficial in processes where temperature control is critical.

4. Design Flexibility The composite nature of FRP allows for greater flexibility in design. Engineers can create vessels tailored to specific requirements, including complex geometries that would be difficult to achieve with traditional materials.

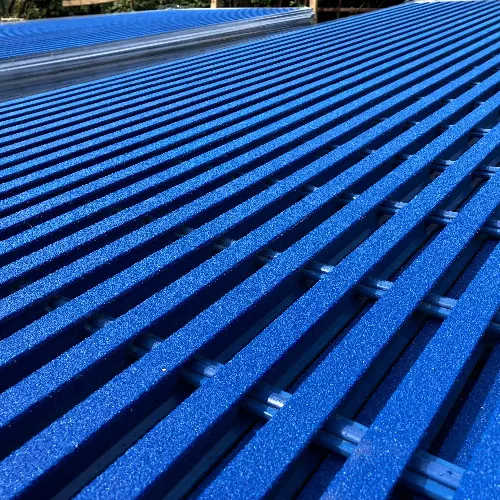

2472 frp vessel

5. Lower Maintenance Costs The durability of FRP vessels, combined with their resistance to corrosion and fatigue, translates to lower maintenance costs over their lifespan. This makes them an economically viable option for many industries.

Applications of the 2472 FRP Vessel

The versatility of the 2472 FRP vessel allows it to be utilized across multiple industries

- Chemical Processing The chemical industry benefits from the corrosion-resistant properties of FRP, making it an ideal choice for storage tanks, pipes, and reactors.

- Water Treatment and Waste Management FRP vessels are increasingly used in the construction of water treatment tanks and systems due to their long-lasting nature and resistance to harsh environmental conditions.

- Aerospace and Automotive In the aerospace and automotive sectors, where weight reduction is critical for efficiency and performance, FRP vessels contribute significantly to achieving these goals.

- Marine Applications The marine industry utilizes FRP vessels for their lightweight and corrosion-resistant properties, providing safer and more efficient options for boat and ship construction.

Conclusion

The 2472 FRP vessel represents a significant advancement in composite engineering, merging strength, durability, and design flexibility. With applications spanning from chemical processing to marine construction, the potential of FRP vessels is immense. As industries continue to seek innovative solutions that offer both performance and cost-effectiveness, the role of FRP vessels like the 2472 will undoubtedly grow, paving the way for a more sustainable and efficient future in engineering. In a world where material performance is tantamount to success, the 2472 FRP vessel stands out as a testament to the power of modern materials in revolutionizing how we build and design.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025