loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Analysis of 2472% FRP Vessel Performance and Applications in Modern Engineering

The Advantages of 2472 FRP Vessels A Comprehensive Overview

In the world of industrial applications, the choice of materials for constructing storage and processing vessels is paramount. One of the most significant advancements in this field has been the development of fiberglass reinforced plastic (FRP) vessels. Among the various types available, 2472 FRP vessels have gained popularity due to their durability, versatility, and cost-effectiveness. In this article, we will explore the key features and benefits of 2472 FRP vessels, particularly in industrial settings.

Material Composition and Structure

2472 FRP vessels are primarily constructed from a composite of fiberglass and resin, providing a lightweight yet robust solution for various applications. The combination of these materials results in exceptional strength-to-weight ratios, making these vessels not only easy to handle but also capable of withstanding significant pressure and stress. Additionally, the use of high-quality resins enhances chemical resistance, allowing these vessels to store a wide range of substances without the risk of degradation.

Corrosion Resistance

One of the standout features of 2472 FRP vessels is their outstanding resistance to corrosion. Traditional materials like steel and aluminum can be susceptible to rust and deterioration when exposed to harsh chemicals, environmental conditions, or moisture. In contrast, FRP vessels are inert and do not corrode, significantly prolonging their lifespan and reducing maintenance costs. This makes them particularly attractive for industries such as chemical processing, wastewater treatment, and food and beverage production, where exposure to corrosive agents is common.

Thermal Insulation

2472 FRP vessels also possess excellent thermal insulation properties. This characteristic is vital for processes that require temperature control, as it helps maintain the integrity of the contents without excessive energy consumption. The insulating properties of FRP reduce heat transfer, contributing to more stable process conditions, which is especially important in applications involving sensitive materials or reactions that are temperature-dependent.

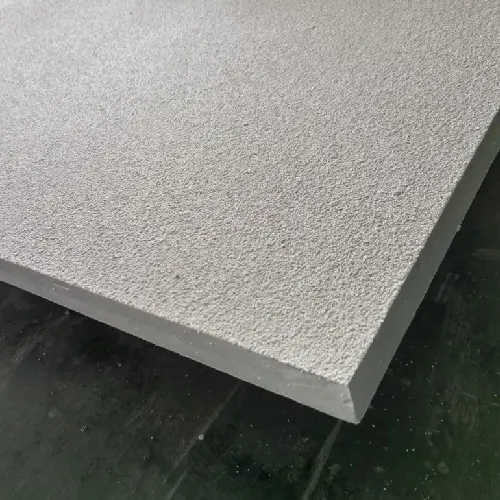

2472 frp vessel

Customizability

Another advantage of 2472 FRP vessels is their versatility in design. Manufacturers can customize the size, shape, and additional features of these vessels to meet specific requirements. This flexibility allows for seamless integration into existing systems, optimizing space and functionality. Whether for storage tanks, pressure vessels, or process vessels, the adaptability of FRP facilitates better engineering solutions tailored to unique operational needs.

Cost-Effectiveness

Although the initial investment in 2472 FRP vessels can be higher than traditional materials, the long-term cost benefits are substantial. The durability and low maintenance requirements of FRP result in reduced lifecycle costs. Furthermore, the energy efficiency derived from thermal insulation leads to savings in operational costs. Overall, the investment in 2472 FRP vessels often pays off, making them a smart choice for businesses seeking to optimize expenditures and enhance productivity.

Environmental Impact

In today’s industrial landscape, sustainability is a crucial consideration. 2472 FRP vessels contribute positively to environmental goals by reducing the likelihood of leaks and spills, thus minimizing the risk of contamination. Their long lifespan means fewer replacements and less waste, aligning with the principles of sustainable manufacturing practices. Additionally, the production of FRP vessels can incorporate recycled materials, further reducing the environmental footprint.

Conclusion

In summary, 2472 FRP vessels present a compelling option for industrial applications requiring high performance, durability, and cost-effectiveness. From their exceptional corrosion resistance and thermal insulation to their customizability and positive environmental impact, these vessels stand out as a reliable choice for a range of industries. As businesses continue to prioritize efficiency and sustainability, the adoption of 2472 FRP vessels is likely to increase, solidifying their position as a vital component in modern industrial practices.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025