loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Design Features of 2472 FRP Vessels for Enhanced Performance and Durability

The Role of 2472 FRP Vessels in Modern Engineering

In the realm of engineering, the demand for innovative and efficient materials is ever-increasing. Among these materials, Fiber Reinforced Polymer (FRP) stands out as a versatile and powerful solution. In particular, the 2472 FRP vessel has garnered attention for its unique characteristics and applications across various industries.

Understanding FRP

Fiber Reinforced Polymer is a composite material made by combining a polymer matrix with fibrous materials. This combination results in a lightweight yet durable product, which is highly resistant to corrosion, fatigue, and impact. The term 2472 refers to specific standards or dimensions, which could relate to the size or specification of a given FRP vessel suitable for various applications, particularly in the fields of storage and transportation.

Key Features of 2472 FRP Vessels

1. Lightweight The specific design of 2472 FRP vessels allows for easy handling and transportation, reducing labor costs and improving efficiency on-site.

2. Corrosion Resistance Unlike traditional metal vessels, FRP bottles are not susceptible to rust or chemical corrosion. This property makes them ideal for storing and transporting aggressive chemicals, such as acids and bases.

3. Durability FRP materials can withstand harsh environments, including extreme temperatures and aggressive substances. This resilience translates to lower maintenance costs and extended shelf life.

4. Customizability The design of 2472 FRP vessels can be tailored to meet specific needs, including size, shape, and internal lining, enhancing their functionality for various industrial applications.

Applications of 2472 FRP Vessels

2472 frp vessel

The versatility of 2472 FRP vessels makes them suitable for a wide range of applications

- Chemical Storage These vessels are commonly used in the chemical industry due to their ability to safely store hazardous materials without risk of contamination or degradation.

- Water Treatment Plants In water treatment processes, FRP vessels are utilized for storage tanks and pressure vessels, offering resistance to various treatment chemicals while maintaining structural integrity.

- Oil and Gas Their lightweight nature and strength make 2472 FRP vessels ideal for use in offshore drilling platforms and storage tanks for oil and gas operations, where weight savings can significantly impact operational efficiency.

- Food and Beverage The sanitary properties of FRP materials make them suitable for the food and beverage industry, where cleanliness and safety are paramount. These vessels can be used for mixing, storing, and transporting various food products without leaching harmful substances.

Sustainability and Environmental Impact

As industries become increasingly aware of their environmental footprint, the sustainability of materials like FRP is a crucial factor. 2472 FRP vessels can contribute to greener practices by extending the lifespan of storage solutions and reducing the need for frequent replacements. Moreover, their recyclability at the end of life positions them favorably in an era that demands sustainable development.

Conclusion

The 2472 FRP vessel exemplifies the innovative strides made in engineering materials, meeting the diverse needs of various industries while minimizing environmental impact. With their lightweight, corrosion-resistant, and durable properties, these vessels are set to play a vital role in modern engineering solutions. As technology progresses and industries evolve, the application and importance of 2472 FRP vessels will only continue to expand, contributing to a more sustainable and efficient future.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

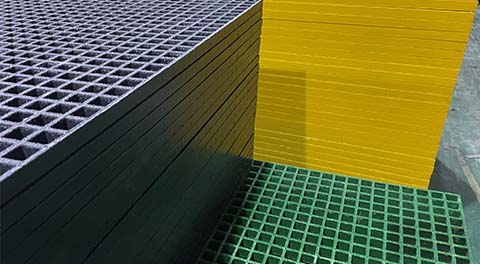

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025