loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1354 frp vessel price

Understanding the Pricing of FRP Vessels The Case of 1354

In the world of engineering and manufacturing, the choice of materials plays a crucial role in determining the durability, efficiency, and overall performance of a product. One such material, frequently used in various industrial applications, is Fiber Reinforced Plastic (FRP). FRP vessels, known for their strength, lightweight nature, and corrosion resistance, have gained enormous popularity across numerous sectors. However, understanding the pricing, particularly in the case of the 1354 model FRP vessel, can be complex due to several influencing factors.

What is FRP?

FRP consists of a polymer matrix reinforced with fibers, typically fiberglass, which offers significant advantages over traditional materials like steel or aluminum. FRP vessels are widely used in chemical storage, water treatment, and other applications requiring material durability in harsh environments. These vessels are less prone to corrosion, reducing maintenance costs and increasing longevity.

The Price of FRP Vessels

Understanding the Pricing of FRP Vessels The Case of 1354

1. Material Costs The base cost of materials, including the resin and fiberglass, significantly affects the final price of the FRP vessel. Variations in the market prices of raw materials can lead to fluctuations in costs. Additionally, the type of fiberglass (E-glass, S-glass, etc.) used can influence pricing due to differences in properties and performance.

1354 frp vessel price

2. Manufacturing Processes The method used to manufacture the FRP vessel also impacts its cost. Techniques like filament winding, pultrusion, or hand lay-up are common. Each of these methods has distinct advantages and costs. For instance, filament winding tends to be more automated and efficient, potentially lowering labor costs and increasing production speed, while hand lay-up may offer more customization at a higher labor cost.

3. Size and Design Specifications The complexity of the design, including size and structural requirements, plays a significant role in pricing. Larger vessels or those with intricate designs often require more materials and more sophisticated manufacturing processes, leading to increased costs. The specific requirements of the 1354 model in terms of volume, pressure rating, and application will thus impact its price.

4. Market Demand and Supply Pricing is not solely based on production costs; market dynamics play a critical role. High demand for FRP vessels can push prices higher, particularly if supply is limited. Understanding the current market trends and potential fluctuations in demand is crucial for determining the price of the 1354 model.

5. Regulatory Factors Compliance with industry standards and regulations can also affect the cost. In certain applications, vessels must meet stringent safety and environmental standards, potentially increasing production costs due to the need for additional testing and certification.

Conclusion

In conclusion, the price of the 1354 FRP vessel is influenced by a unique interplay of material costs, manufacturing processes, size and design specifications, market demand, and regulatory factors. For businesses considering the procurement of FRP vessels, it is essential to evaluate these elements carefully. While FRP vessels may have a higher upfront cost compared to traditional materials, their long-term benefits—such as reduced maintenance, extended lifespan, and lower risk of corrosion—can result in significant cost savings over time. Understanding these dynamics ensures informed decision-making and maximizes investment returns in industrial applications.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

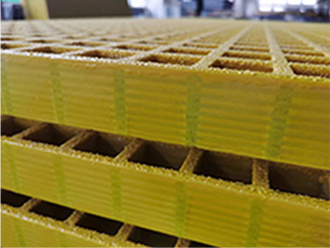

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025