loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1354 frp vessel

Understanding 1354 FRP Vessels Innovations in Composite Technology

In the contemporary landscape of engineering applications, the use of Fiber Reinforced Plastics (FRP) has gained paramount importance due to their remarkable properties such as high strength-to-weight ratios, corrosion resistance, and design flexibility. Among various types of FRP vessels, the 1354 FRP vessel stands out as a fine representation of the advancements in composite technology, specifically designed to meet the challenges posed by diverse industrial requirements.

The acronym 1354 is often interpreted as a designation that could reflect specific standards or specifications associated with the manufacturing and application of these FRP vessels. The uniqueness of such naming conventions often denotes particular characteristics such as size, material formulations, or compliance with industry regulations. It is essential to delve into the attributes of FRP vessels to appreciate the significance of these standards.

Properties of FRP Vessels

FRP vessels are constructed using a combination of resin and reinforcement fibers, the most common being glass fibers, but carbon and aramid fibers are also used for specialized applications. These composite materials exhibit several key properties

1. Lightweight One of the most notable advantages of FRP vessels is their lightweight nature compared to traditional materials such as steel or concrete. This allows for easier handling, transportation, and installation.

2. Corrosion Resistance FRP vessels are highly resistant to chemical attacks, which makes them ideal for use in corrosive environments found in industries such as chemical processing, water treatment, and marine applications.

3. High Strength and Durability Despite their lightweight, FRP vessels possess excellent mechanical strength. They can endure high pressures and temperatures, proving their reliability in demanding conditions.

4. Design Flexibility The versatility of the materials used in FRP construction enables engineers to design vessels in various shapes and sizes, tailored to specific project requirements.

Applications of 1354 FRP Vessels

The 1354 FRP vessel is particularly well-suited for a range of applications across different sectors

1354 frp vessel

- Water Treatment In water treatment facilities, these vessels are used for storage and transport of various chemicals, thanks to their resistance to corrosion and ability to maintain structural integrity over time.

- Chemical Processing The chemical industry relies on FRP vessels for their ability to resist harsh environments. They are often employed in reactors, storage tanks, and piping systems where traditional materials would fail.

- Oil and Gas In the oil and gas sector, 1354 FRP vessels can be utilized for storage and transportation of corrosive fluids, ensuring safety and reliability in operations.

- Marine The lightweight and corrosion-resistant properties of FRP vessels make them ideal for maritime applications, including cargo tanks and recreational boats.

Production Techniques

The manufacturing process for FRP vessels involves advanced techniques such as filament winding, hand lay-up, and vacuum infusion. These methods allow for precise control over the fiber orientation and resin application, resulting in superior material properties. Modern manufacturing technologies have significantly improved the efficiency and quality of FRP vessel production, reinforcing their position in the market.

Compliance and Standards

Given the critical applications of FRP vessels, adherence to industry standards and regulations is of utmost importance. The 1354 designation likely pertains to specific compliance guidelines that ensure the vessels are safe and effective for their intended use. Certifications from relevant authorities, such as the American Society of Mechanical Engineers (ASME) or the American National Standards Institute (ANSI), may apply.

Conclusion

The evolution of composite technology has ushered in the era of FRP vessels, with the 1354 variant embodying the cutting-edge enhancements in this field. Their lightweight nature, corrosion resistance, and design flexibility have made them indispensable in various industries. As technology advances and the demand for innovative solutions grows, FRP vessels are likely to continue their expansion, reinforcing the importance of standards like the 1354 in ensuring safety, efficiency, and sustainability in industrial applications. Overall, the future looks promising for FRP vessels as they meet the ever-evolving engineering challenges of our time.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

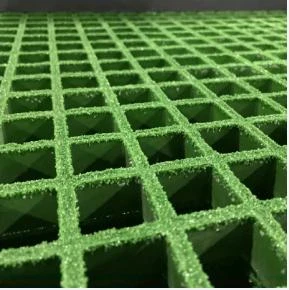

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025