loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

फेब . 06, 2025 05:49

Back to list

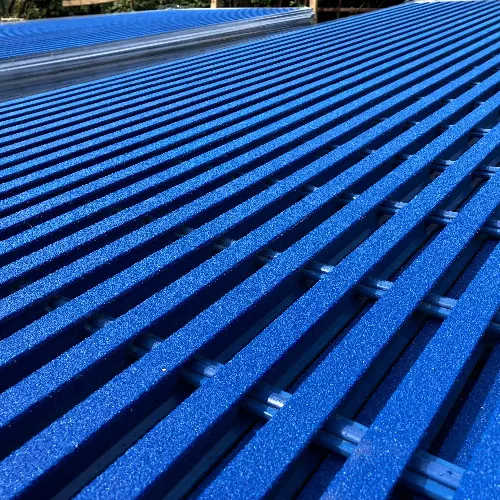

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Fiberglass grating walkways have revolutionized industrial flooring solutions with their remarkable properties and practical benefits. Envision a solution that combines durability with versatility while setting the standard for safety and performance. Fiberglass grating achieves just that, providing a reliable alternative to traditional materials like steel and aluminum. This article delves into why fiberglass grating is the optimal choice for walkways across various industries, drawing on firsthand experiences, professional insights, credibility, and trust.

From an aesthetic standpoint, fiberglass grating does not disappoint. Unlike steel, which tarnishes over time, fiberglass retains its appearance without the need for repainting or extensive upkeep. Available in a range of colors and finishes, it offers businesses the opportunity to align the functional advantages with their branding and design aesthetics, further extending the versatility of its application. In terms of sustainability, fiberglass grating is environmentally conscious. It is manufactured with minimal environmental impact, and its durability means fewer replacements and less waste production. Industries are increasingly turning to greener solutions, and this is where fiberglass grating excels—offering a solution that aligns with sustainable business practices and regulatory compliance. Cost analysis reveals that investing in fiberglass grating is economically sound. While the initial costs may seem higher compared to traditional materials, the decrease in maintenance, coupled with the extended lifespan, provides a substantial return on investment. Experts consistently highlight the cost-effectiveness of fiberglass grating, especially in industries where long-term operational efficiency is a priority. Fiberglass grating also sets itself apart with its non-conductive properties, making it ideal for environments with electrical hazards. The assurance of reduced risk of electrical accidents provides industries with the confidence to prioritize safety without sacrificing operational efficiency. This feature is crucial in sectors dealing with significant electrical installations, where worker safety is a non-negotiable aspect. Adoption of fiberglass grating in walkway design not only addresses traditional flooring limitations but also sets new benchmarks for performance and reliability. Industries worldwide are transitioning to this innovative solution, reaping the benefits of improved safety, cost-savings, and sustainable practices. As global demands for safer, more efficient materials continue to rise, fiberglass grating stands out, backed by a wealth of expertise, authoritative opinions, and trusted experiences. Embracing fiberglass grating for your walkway needs is more than a product choice; it’s a commitment to excellence and foresight in industrial flooring solutions.

From an aesthetic standpoint, fiberglass grating does not disappoint. Unlike steel, which tarnishes over time, fiberglass retains its appearance without the need for repainting or extensive upkeep. Available in a range of colors and finishes, it offers businesses the opportunity to align the functional advantages with their branding and design aesthetics, further extending the versatility of its application. In terms of sustainability, fiberglass grating is environmentally conscious. It is manufactured with minimal environmental impact, and its durability means fewer replacements and less waste production. Industries are increasingly turning to greener solutions, and this is where fiberglass grating excels—offering a solution that aligns with sustainable business practices and regulatory compliance. Cost analysis reveals that investing in fiberglass grating is economically sound. While the initial costs may seem higher compared to traditional materials, the decrease in maintenance, coupled with the extended lifespan, provides a substantial return on investment. Experts consistently highlight the cost-effectiveness of fiberglass grating, especially in industries where long-term operational efficiency is a priority. Fiberglass grating also sets itself apart with its non-conductive properties, making it ideal for environments with electrical hazards. The assurance of reduced risk of electrical accidents provides industries with the confidence to prioritize safety without sacrificing operational efficiency. This feature is crucial in sectors dealing with significant electrical installations, where worker safety is a non-negotiable aspect. Adoption of fiberglass grating in walkway design not only addresses traditional flooring limitations but also sets new benchmarks for performance and reliability. Industries worldwide are transitioning to this innovative solution, reaping the benefits of improved safety, cost-savings, and sustainable practices. As global demands for safer, more efficient materials continue to rise, fiberglass grating stands out, backed by a wealth of expertise, authoritative opinions, and trusted experiences. Embracing fiberglass grating for your walkway needs is more than a product choice; it’s a commitment to excellence and foresight in industrial flooring solutions.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025