loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

heavy duty bar grating

Heavy Duty Bar Grating An Essential Component in Industrial Applications

Heavy duty bar grating is a pivotal element in various industrial applications, offering robust solutions for flooring, walkways, platforms, and drainage systems. Designed to support heavy loads while maintaining safety and efficiency, this type of grating is widely utilized in sectors such as manufacturing, construction, transportation, and energy.

One of the primary advantages of heavy duty bar grating is its strength. Constructed from materials like steel, aluminum, or fiberglass, heavy duty bar grating is engineered to withstand severe conditions, including heavy foot traffic and machinery loads. The load-bearing capacity is determined by the size, spacing, and type of bars used in the grating. Typically, the bars are arranged in a grid pattern, with the spans between them customized based on the specific requirements of the application. This customization ensures that the grating can bear the necessary weight without compromising safety.

Another significant benefit of heavy duty bar grating is its durability. Unlike traditional flooring options such as concrete or wood, heavy duty grating is resistant to corrosion, chemicals, and extreme temperatures. For instance, stainless steel grating offers superior resistance to rust and degradation, making it ideal for environments like wastewater treatment plants or chemical processing facilities, where exposure to harsh substances is common. As a result, investing in heavy duty bar grating can lead to reduced maintenance costs and a longer lifespan, providing significant value to businesses.

Moreover, heavy duty bar grating enhances safety in industrial settings. Its open design supports excellent drainage and air circulation, preventing the accumulation of water, debris, and hazardous materials on the surface. This feature is crucial in reducing slip and fall accidents, which are prevalent in many industrial environments. Additionally, the visibility of the grating allows workers to see potential hazards, thereby increasing situational awareness and overall workplace safety.

heavy duty bar grating

Installation of heavy duty bar grating is typically straightforward. It can be pre-fabricated to specific dimensions and shapes, allowing for quick assembly and minimal disruption to ongoing operations. Most systems utilize a bolt-down or weld-down approach for securing the grating, depending on the application and environmental conditions. With proper installation techniques, heavy duty bar grating can also be integrated with existing structures or systems, further enhancing its versatility.

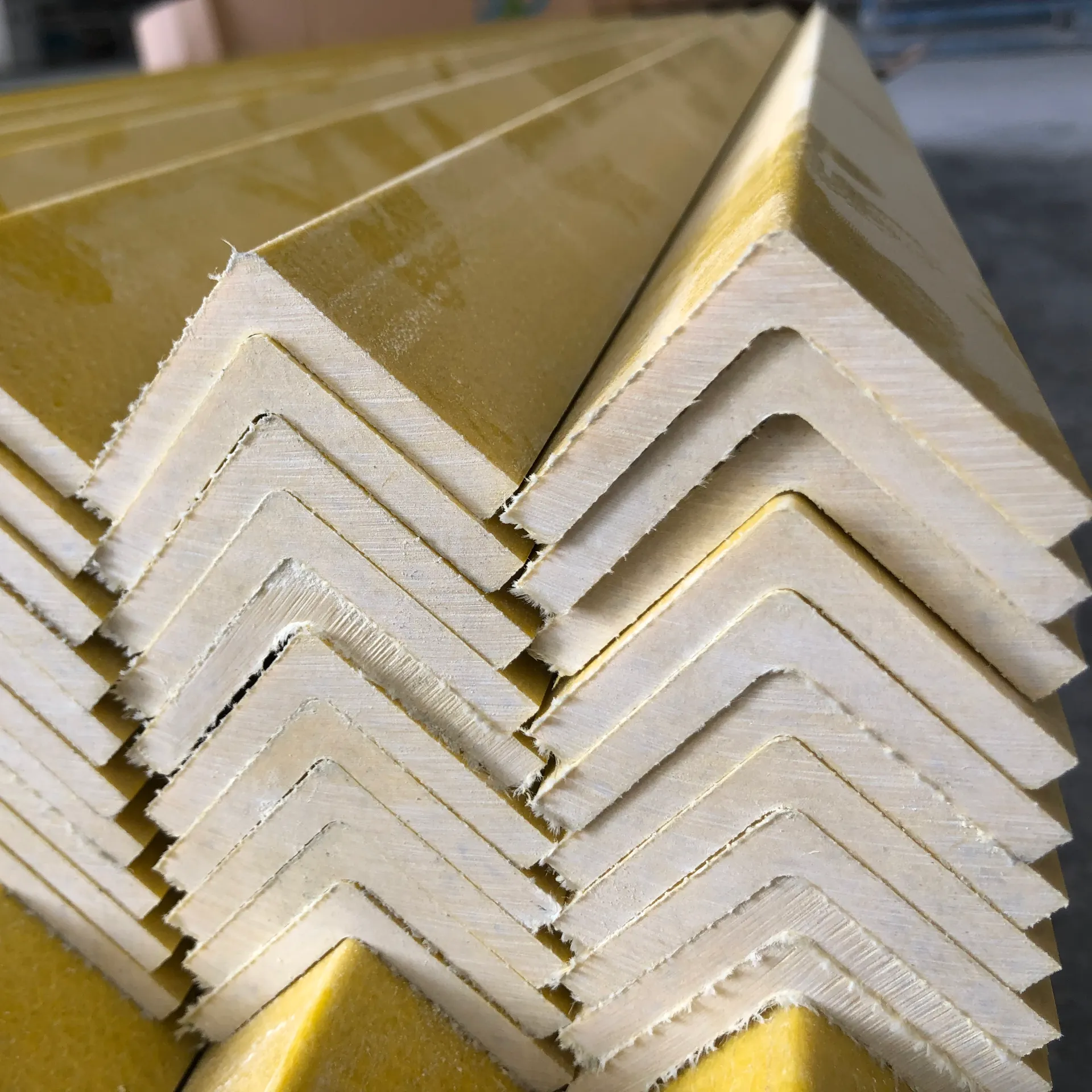

One of the key considerations when selecting heavy duty bar grating is the choice of materials. While steel is the most common material due to its high strength and load-bearing capacity, alternatives like aluminum and fiberglass are gaining traction. Aluminum is lightweight and resistant to corrosion, making it a popular choice for applications requiring portability and ease of handling. Fiberglass, on the other hand, offers excellent resistance to chemicals and is non-conductive, making it ideal for electrical environments. Each material presents unique advantages, and the choice often hinges on the specific demands of the application.

Sustainability is becoming increasingly significant in industrial design, and heavy duty bar grating aligns well with eco-friendly initiatives. Many manufacturers create grating systems from recycled materials, reducing environmental impact while offering durability and performance. Furthermore, the longevity of heavy duty grating contributes to a decrease in waste generated from frequent replacements, aligning with sustainable practices in construction and industrial operations.

In conclusion, heavy duty bar grating serves as a vital component in various industrial applications, providing strength, durability, safety, and sustainability. Its ability to support heavy loads, resist corrosion, and enhance workplace safety makes it an invaluable asset in sectors where reliability is crucial. As industries evolve and seek more efficient and sustainable solutions, heavy duty bar grating will undoubtedly continue to play a significant role in the future of industrial infrastructure. Whether in manufacturing, construction, or any other field, embracing the advantages of heavy duty bar grating is a strategic choice that can foster operational success and enhance workplace safety.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025