loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 09, 2025 10:51

Back to list

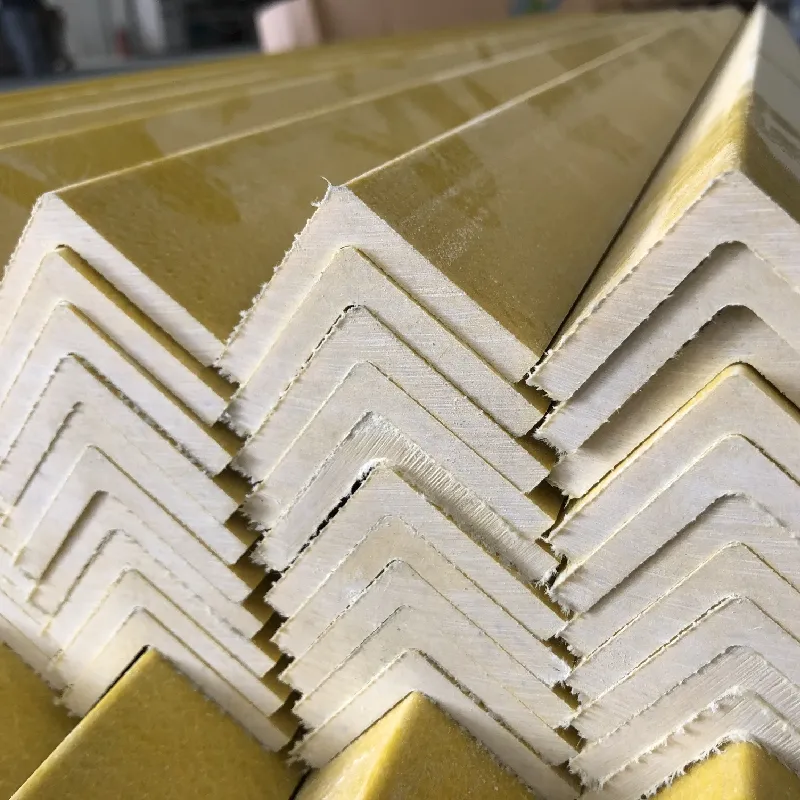

frp pultruded gratings

Pultruded FRP grating is revolutionizing the way industries approach construction and maintenance projects, offering a combination of flexibility, durability, and cost-effectiveness. As someone who has spent over two decades in the advanced composite materials industry, I can assure you that choosing the right type of grating is crucial for the success and longevity of various engineering applications.

Trust becomes a critical factor when selecting materials for projects that demand the utmost reliability. Pultruded FRP grating has earned a reputation for enhanced safety features. Its anti-slip surface reduces the risk of accidents in wet or oily conditions, making it a preferred choice for walkways and platforms in industrial settings. Its design facilitates drainage and ventilation, further enhancing workplace safety. When leveraging pultruded FRP grating, professionals appreciate its ease of installation, which does not require heavy lifting equipment. This benefit not only reduces installation costs but also increases turnaround times, allowing projects to meet tight deadlines without compromising quality or safety. For construction managers and engineers seeking products that align with sustainable practices, pultruded FRP grating offers an environmentally friendly solution. The production process minimizes waste, and the material itself is fully recyclable, contributing to a reduced carbon footprint. Conclusively, pultruded FRP grating stands out as a testament to technological advancement in composite materials. Its adoption not only signals an industry shift towards more sustainable practices but also highlights an ongoing commitment to safety, efficiency, and reliability. As such, it's becoming the preferred material choice across various sectors globally, solidifying its authority in modern engineering and design.

Trust becomes a critical factor when selecting materials for projects that demand the utmost reliability. Pultruded FRP grating has earned a reputation for enhanced safety features. Its anti-slip surface reduces the risk of accidents in wet or oily conditions, making it a preferred choice for walkways and platforms in industrial settings. Its design facilitates drainage and ventilation, further enhancing workplace safety. When leveraging pultruded FRP grating, professionals appreciate its ease of installation, which does not require heavy lifting equipment. This benefit not only reduces installation costs but also increases turnaround times, allowing projects to meet tight deadlines without compromising quality or safety. For construction managers and engineers seeking products that align with sustainable practices, pultruded FRP grating offers an environmentally friendly solution. The production process minimizes waste, and the material itself is fully recyclable, contributing to a reduced carbon footprint. Conclusively, pultruded FRP grating stands out as a testament to technological advancement in composite materials. Its adoption not only signals an industry shift towards more sustainable practices but also highlights an ongoing commitment to safety, efficiency, and reliability. As such, it's becoming the preferred material choice across various sectors globally, solidifying its authority in modern engineering and design.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025