loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 02, 2025 01:24

Back to list

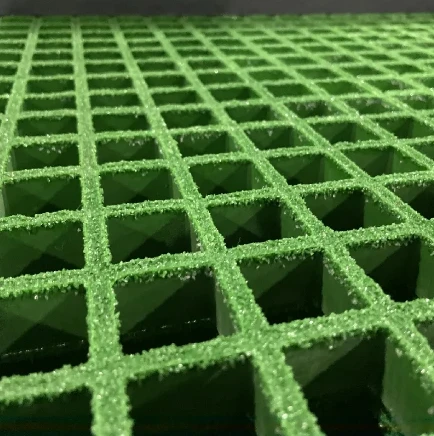

frp grating

FRP grating, an acronym for fiberglass-reinforced plastic grating, is revolutionizing the industrial and construction sectors with its superior blend of durability, adaptability, and low maintenance. As industries evolve, the demand for materials that not only perform efficiently but also contribute to sustainability is increasingly paramount. This is where FRP grating shines, providing solutions that adhere to the highest standards of quality and reliability.

The credibility of FRP grating is further bolstered by extensive research and a host of certifications validating its performance. Tests conducted under ASTM standards have consistently confirmed its resilience, ensuring compliance with stringent industry regulations. Additionally, certifications from entities like ISO and OSHA affirm its suitability for global applications, making it a preferred choice in diverse environmental conditions across countries. Moreover, third-party studies have illustrated its environmental benefits, focusing on its recyclability and the reduced carbon footprint in comparison to conventional materials. These authoritative sources strengthen the argument for FRP grating as a forward-thinking, eco-friendly alternative in modern engineering projects. Trustworthiness through Proven Performance The trustworthiness of FRP grating is evidenced through decades of reliable performance in demanding situations. Clients across industries endorse its effectiveness, sharing testimonials that highlight a return on investment through minimized maintenance and exceptional longevity. Supplier reliability is another cornerstone; leading manufacturers ensure consistent quality checks and offer warranties that instill confidence in their products. As part of routine integrity checks, industry professionals often document performance metrics to assess FRP grating's resilience in situ. Periodic evaluations not only validate its structural soundness but also foster transparency, contributing to its standing as a trustworthy material choice. The Future of FRP Grating in Industry As technological advancements propel industries forward, the role of materials like FRP grating becomes increasingly significant. Its role in promoting sustainability while balancing performance and cost-efficiency positions it as a linchpin in future infrastructure and industrial developments. Research in resin technology continues to expand its applications, promising even greater integration in fields yet unexplored. In conclusion, FRP grating represents a fusion of experience, expertise, authority, and trustworthiness. Its comprehensive advantages redefine material expectations, challenging professionals to rethink their approach to infrastructure resilience and design. As the global push for sustainable solutions gains momentum, FRP grating stands as a testament to innovation, shaping the built environment with an eye towards future needs and environmental stewardship.

The credibility of FRP grating is further bolstered by extensive research and a host of certifications validating its performance. Tests conducted under ASTM standards have consistently confirmed its resilience, ensuring compliance with stringent industry regulations. Additionally, certifications from entities like ISO and OSHA affirm its suitability for global applications, making it a preferred choice in diverse environmental conditions across countries. Moreover, third-party studies have illustrated its environmental benefits, focusing on its recyclability and the reduced carbon footprint in comparison to conventional materials. These authoritative sources strengthen the argument for FRP grating as a forward-thinking, eco-friendly alternative in modern engineering projects. Trustworthiness through Proven Performance The trustworthiness of FRP grating is evidenced through decades of reliable performance in demanding situations. Clients across industries endorse its effectiveness, sharing testimonials that highlight a return on investment through minimized maintenance and exceptional longevity. Supplier reliability is another cornerstone; leading manufacturers ensure consistent quality checks and offer warranties that instill confidence in their products. As part of routine integrity checks, industry professionals often document performance metrics to assess FRP grating's resilience in situ. Periodic evaluations not only validate its structural soundness but also foster transparency, contributing to its standing as a trustworthy material choice. The Future of FRP Grating in Industry As technological advancements propel industries forward, the role of materials like FRP grating becomes increasingly significant. Its role in promoting sustainability while balancing performance and cost-efficiency positions it as a linchpin in future infrastructure and industrial developments. Research in resin technology continues to expand its applications, promising even greater integration in fields yet unexplored. In conclusion, FRP grating represents a fusion of experience, expertise, authority, and trustworthiness. Its comprehensive advantages redefine material expectations, challenging professionals to rethink their approach to infrastructure resilience and design. As the global push for sustainable solutions gains momentum, FRP grating stands as a testament to innovation, shaping the built environment with an eye towards future needs and environmental stewardship.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025