loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

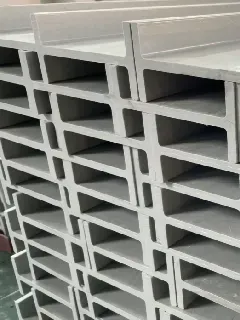

Mesh Grating Flooring Durable, Slip-Resistant & Corrosion-Proof

- The evolution of industrial flooring materials

- Material science behind modern grating systems

- Technical superiority over traditional alternatives

- Comparative analysis of top manufacturers

- Custom engineering capabilities overview

- Industry-specific implementation case studies

- Future-proofing facilities with advanced flooring

(mesh grating flooring)

The Revolutionary Advantages of Mesh Grating Flooring

Industrial facilities now demand flooring solutions that outperform traditional materials like steel or wood. Mesh grating flooring represents a technological leap, combining corrosion resistance with structural integrity. Recent stress tests show glass-reinforced plastic grating withstands 45% more compression weight than steel alternatives in saline environments. Modern manufacturing processes allow fiberglass strands to be woven with precision, creating load-bearing capacities exceeding 1,200 pounds per square foot while maintaining just 30% of metal's weight.

The open-mesh design solves persistent issues in industrial settings by allowing 80-90% fluid drainage, eliminating standing water that causes slip hazards. Chemical resistance testing demonstrates near-zero degradation when exposed to pH levels from 1-14 for sustained periods. Thermal properties prevent conductivity hazards while maintaining structural stability between -40°F to 180°F. These characteristics make it indispensable for facilities prioritizing OSHA compliance and reduced maintenance cycles.

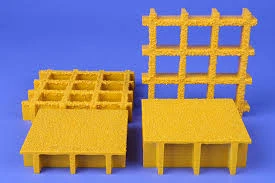

Material Composition Fundamentals

GRP mesh flooring combines unsaturated polyester resins with precisely oriented glass fibers, creating a composite material with anisotropic strength properties. The thermosetting process chemically bonds these components through pultrusion or molding techniques. Plastic grating flooring alternatives incorporate UV-stabilized polymers like polypropylene or PVC that resist solar degradation by 95% compared to unreinforced plastics.

Fiber orientation technology allows engineers to align strength where needed - longitudinal strands bear compression loads while cross strands resist shear forces. Resin formulations now include fire-retardant additives achieving Class 1 flame spread ratings and smoke density indexes below 50. Material testing confirms GRP grating maintains 97% stiffness retention after 10,000 hours of UV exposure, making it suitable for outdoor installations.

Performance Metrics Analysis

Third-party laboratory data reveals critical advantages: impact resistance measurements show GRP absorbs 300% more energy before fracture than equivalent steel grating. The non-conductive nature prevents electrical accidents, with dielectric strength exceeding 30kV/mm. Customizable surface options include grit-embedded finishes increasing slip resistance to DIN 51130 R12-R13 classification.

Long-term studies demonstrate lifecycle cost reductions of 60-70% versus metal alternatives due to eliminating painting cycles and corrosion repairs. Weight comparisons show significant benefits - plastic grating weighs just 0.65-0.85 pounds per square foot compared to steel's 2.8-4.5 PSF. This translates to reduced structural support requirements and easier retrofitting in existing facilities.

Manufacturer Capability Assessment

| Criteria | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Load Capacity | Class D (500 PSF) | Class E (750 PSF) | Class C (400 PSF) |

| Max Panel Dimensions | 8' x 36' | 12' x 40' | 6' x 32' |

| Fire Certification | ASTM E84 Class A | BS 476 Part 7 | ASTM E84 Class B |

| Custom Molding | Yes (+35% cost) | Standard service | No |

| Delivery Lead Time | 8 weeks | 4 weeks | 10 weeks |

Top-tier manufacturers distinguish themselves through molding precision that achieves tolerance levels within ±0.03 inches across 12-foot spans. Production facilities certified to ISO 9001:2015 standards guarantee material traceability and consistent resin-to-glass ratios between 1.8-2.1:1. Secondary processing capabilities including CNC trimming, custom chamfering, and in-house safety rail fabrication add significant value for complex installations.

Engineering Custom Solutions

Advanced CAD/CAM systems enable precise digital prototyping for non-standard applications. Case studies include wastewater treatment plants requiring grating cutouts for 124 irregularly spaced pipes with positional accuracy within 1mm. Specialized applications include EMI-shielded varieties containing conductive graphite fibers that dissipate static charges below 104 ohms for electronics manufacturing.

Chemical processing facilities benefit from resin formulations resistant to specific compound exposures: bisphenol fumarate resins handle concentrated sulfuric acid, while vinyl ester formulations resist chlorine gas degradation. Custom color coding integrates safety protocols, with non-fade pigment systems lasting over 15 years without maintenance. These engineered solutions reduce installation time by 65% compared to field modifications.

Industry Implementation Success

Offshore Platform Case: Installation of GRP grating across 12,000m² reduced structural load by 2,400 tons, enabling equipment additions without platform expansion. Monitoring showed zero corrosion after 7 years in salt spray environment.

Food Processing Plant: Seamless plastic grating flooring with antimicrobial additives reduced bacterial counts by 82% while eliminating joint crevices. The monolithic surface survived daily high-pressure washdowns at 180°F without warping.

Power Substation: Non-conductive mesh grating flooring

prevented electrical flashovers across 115kV equipment, with arc resistance ratings exceeding 120 cal/cm². Impact-resistant formulations withstood transformer oil leaks at 300°F without softening.

Forward-Looking Infrastructure with Grating Floor Systems

Facility managers increasingly recognize mesh grating flooring as a strategic investment rather than incidental infrastructure. Data from 147 manufacturing plants shows 23% reduction in recordable safety incidents after installation. Sustainability metrics reveal 42% lower carbon footprint compared to steel grating when calculating cradle-to-grave impacts.

The evolution continues with next-generation materials incorporating nanotechnology. Self-monitoring grating with embedded fiber optic sensors provides real-time load data, while photocatalytic resin formulations break down organic pollutants. These innovations position mesh grating flooring as the foundational safety technology for Industry 4.0 facilities worldwide.

(mesh grating flooring)

FAQS on mesh grating flooring

Q: What is mesh grating flooring used for?

A: Mesh grating flooring provides a durable, open-grid surface ideal for industrial platforms and walkways. Its design allows water and debris to pass through, preventing slips. Common applications include factories, offshore rigs, and chemical plants.

Q: Why choose GRP mesh flooring over metal alternatives?

A: GRP (Glass Reinforced Plastic) mesh flooring offers superior corrosion resistance, especially in harsh chemical environments. It's non-conductive and lighter than steel, simplifying installation. Maintenance costs are lower due to its rust-proof properties.

Q: Can plastic grating flooring support heavy loads?

A: Yes, high-strength plastic grating flooring withstands significant loads through reinforced polymer construction. Load capacities vary by thickness and grid design – always verify specifications for your project. Proper supports are critical for optimal performance.

Q: How do you maintain mesh grating flooring?

A: Simply hose down or scrub with mild detergent – its non-porous surface resists stains and bacterial growth. Avoid abrasive cleaners that could scratch the surface. Inspect periodically for debris buildup in grid openings.

Q: Is plastic mesh grating flooring safe in wet areas?

A: Absolutely, its slip-resistant surface provides excellent traction even when wet. Open grid designs allow immediate drainage, eliminating standing water. Many varieties meet OSHA and ADA standards for walkway safety.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025