loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 13, 2025 02:19

Back to list

frp vessel for water treatment

The term FRP vessel 1865 refers to a specialized product category within composite materials engineering, particularly focusing on the use of Fiber Reinforced Plastics (FRP) in constructing vessels. These vessels are renowned for their corrosion resistance, high strength-to-weight ratio, and versatility across various industrial applications.

In terms of expertise, the production of FRP vessels requires specialized knowledge and skills. Manufacturers must consider various factors such as the type of resin and reinforcement materials, the intended operating conditions, and the specific configuration of the vessel to ensure optimal performance. As a result, collaboration with engineering experts is critical. These professionals apply sophisticated techniques like finite element analysis (FEA) and computational fluid dynamics (CFD) to design vessels that meet stringent industry standards and customer specifications. Authoritativeness in the manufacturing process is achieved through adherence to global standards such as ASTM or ISO, which set rigorous benchmarks for quality and safety. These standards guide manufacturers in selecting appropriate materials, utilizing advanced production techniques, and conducting thorough testing to ensure the reliability of the final product. Compliance with these standards not only guarantees product quality but also instills confidence in customers worldwide. Trustworthiness is further reinforced by the track record of successful installations across various sectors. Case studies and testimonials from satisfied clients provide tangible proof of the efficacy and reliability of FRP vessels. Clients report significant improvements in operational efficiency and cost savings, citing these vessels' resistance to leaks and breakdowns as major factors contributing to seamless operations. In conclusion, FRP vessels symbolize the intersection of innovative material science and practical industrial application, distinguished by their historical evolution and modern technological advancements. As industries continue to evolve, the demand for reliable, efficient, and durable containment solutions like FRP vessels is expected to grow, cementing their place as a cornerstone of modern industrial infrastructure.

In terms of expertise, the production of FRP vessels requires specialized knowledge and skills. Manufacturers must consider various factors such as the type of resin and reinforcement materials, the intended operating conditions, and the specific configuration of the vessel to ensure optimal performance. As a result, collaboration with engineering experts is critical. These professionals apply sophisticated techniques like finite element analysis (FEA) and computational fluid dynamics (CFD) to design vessels that meet stringent industry standards and customer specifications. Authoritativeness in the manufacturing process is achieved through adherence to global standards such as ASTM or ISO, which set rigorous benchmarks for quality and safety. These standards guide manufacturers in selecting appropriate materials, utilizing advanced production techniques, and conducting thorough testing to ensure the reliability of the final product. Compliance with these standards not only guarantees product quality but also instills confidence in customers worldwide. Trustworthiness is further reinforced by the track record of successful installations across various sectors. Case studies and testimonials from satisfied clients provide tangible proof of the efficacy and reliability of FRP vessels. Clients report significant improvements in operational efficiency and cost savings, citing these vessels' resistance to leaks and breakdowns as major factors contributing to seamless operations. In conclusion, FRP vessels symbolize the intersection of innovative material science and practical industrial application, distinguished by their historical evolution and modern technological advancements. As industries continue to evolve, the demand for reliable, efficient, and durable containment solutions like FRP vessels is expected to grow, cementing their place as a cornerstone of modern industrial infrastructure.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

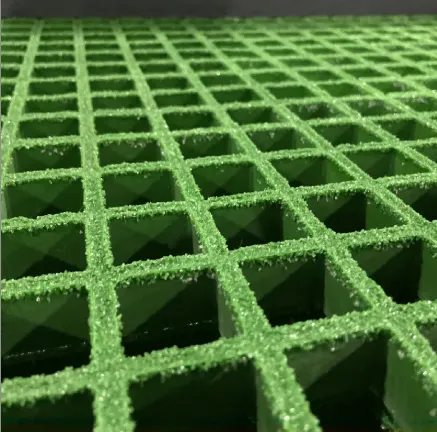

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025