loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp filter vessel

Understanding the FRP Filter Vessel A Key Component in Modern Filtration Systems

In recent years, the demand for efficient and reliable filtration systems has significantly increased across various industries, including water treatment, chemical processing, and food and beverage production. A critical component of these systems is the FRP (Fiberglass Reinforced Plastic) filter vessel, which combines durability, lightweight design, and corrosion resistance to meet the rigorous demands of modern filtration processes.

What is an FRP Filter Vessel?

An FRP filter vessel is a type of container made primarily from fiberglass reinforced plastic. This composite material is known for its exceptional strength-to-weight ratio, making it an ideal choice for filter vessels, which must withstand high pressures and harsh chemical environments. The FRP material is typically created by combining a thermosetting resin with fiberglass, resulting in a product that is both strong and resistant to corrosion.

Advantages of FRP Filter Vessels

1. Corrosion Resistance One of the most significant advantages of FRP over traditional materials like steel is its resistance to corrosion. Since many filtration applications involve exposure to corrosive substances, FRP filter vessels can extend the lifespan of the equipment and reduce maintenance costs.

2. Lightweight Design FRP filter vessels are significantly lighter than their metal counterparts. This lightweight nature makes them easier to handle, transport, and install, helping to reduce overall labor costs and increasing operational efficiency.

3. Customization FRP vessels can be manufactured in various shapes and sizes, tailored to specific applications and requirements. This customization capability allows for flexibility in design and the ability to create systems that can accommodate unique filtration needs.

4. Thermal Insulation The insulating properties of FRP also play a vital role in maintaining the temperature of the contents within the vessel. This feature is particularly beneficial in applications where temperature control is necessary for effective filtration.

5. Cost-Effectiveness Although the initial investment for FRP filter vessels may be higher than some traditional options, the long-term savings from reduced maintenance, increased lifespan, and operational efficiency often result in a lower total cost of ownership.

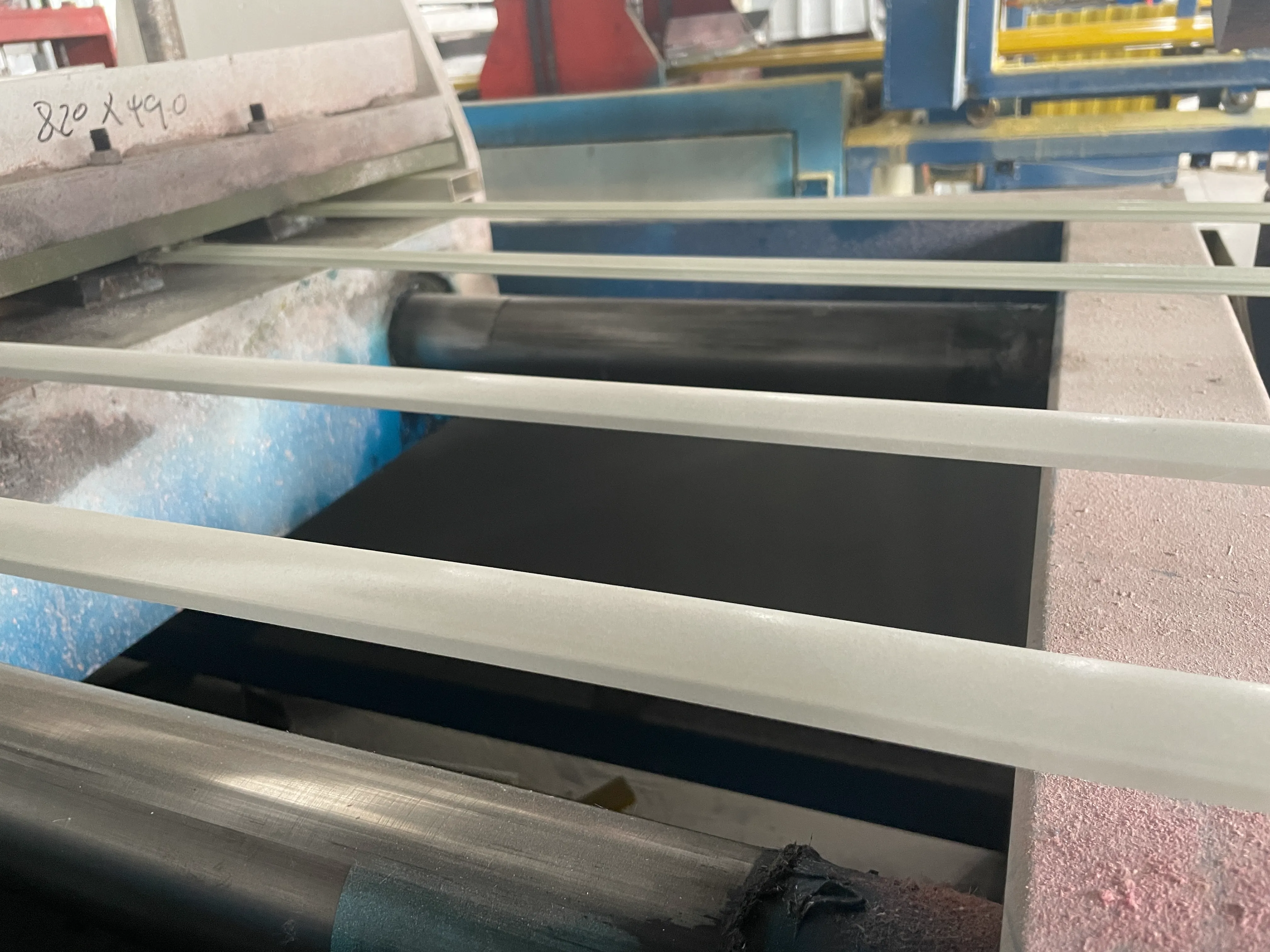

frp filter vessel

Applications of FRP Filter Vessels

FRP filter vessels find applications in numerous fields

- Water Treatment In municipal and industrial water treatment plants, FRP filter vessels are commonly used for sedimentation, filtration, and purification processes, ensuring that clean water is available for consumption and industrial use.

- Chemical Processing Many chemicals can be highly corrosive, making FRP vessels suitable for handling various aggressive media in chemical manufacturing and processing plants.

- Food and Beverage In the food and beverage industry, maintaining hygiene and preventing contamination is critical. FRP filter vessels can effectively handle the filtration of liquids while ensuring compliance with safety standards.

Maintenance and Care

While FRP filter vessels are known for their resilience, regular inspection and maintenance are crucial to ensure optimal performance. It is essential to check for any signs of wear, damage, or degradation of the fiberglass material, especially in high-stress environments. Proper cleaning and adherence to operating guidelines will also help maintain the functionality and longevity of the filter vessels.

Conclusion

The FRP filter vessel represents a significant advancement in filtration technology, offering numerous advantages over traditional materials. Its unique properties make it suitable for a diverse range of applications, ensuring that industries can meet their filtration needs efficiently and effectively. As the demand for robust filtration solutions continues to grow, FRP filter vessels will undoubtedly play a pivotal role in shaping the future of filtration technology.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025