loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

High-Strength FRP Handrails for Industrial Safety Durable FRP Channel & Rectangular Tube Solutions

- Introduction: The importance and growing applications of frp handrails

. - Technical Advantages: Strength, corrosion resistance, and maintenance aspects.

- Manufacturer Comparison: Leading suppliers evaluated using a data table.

- Customization Options: Detailed look into tailored FRP solutions, including FRP channels and rectangular tubes.

- Application Scenarios: Real-world usage in various industries, supported by case data.

- Installation and Maintenance: Key considerations for long-term performance.

- Conclusion: Why frp handrails offer unmatched value in modern infrastructure projects.

(frp handrails)

Unlocking the Potential of frp handrails in Modern Infrastructure

As industries evolve to demand greater performance, safety, and cost efficiency, the utilization of frp handrails (Fiber Reinforced Polymer handrails) has surged dramatically. According to a 2023 MarketsandMarkets report, the global market for FRP products, including handrails, is projected to reach $6.5 billion by 2027, growing at a CAGR of 6.1% from 2022. This rise is fueled by the increasing adoption of advanced composites in construction, chemical processing plants, coastal infrastructural developments, and transportation frameworks.

FRP handrails combine lightweight structure with impressive mechanical durability, making them attractive for settings where steel and aluminum would corrode, fatigue, or require frequent maintenance. The advent of tailored FRP channel and frp rectangular tube designs has further pushed their applicability, allowing for customized installations in irregular or high-stress environments. The next sections delve deeper into technical features, competitive manufacturer landscapes, and tailored solution pathways for integrators and specifiers seeking both efficiency and longevity.

Technical Advantages: Performance That Sets the Standard

At the core of frp handrails’ increasing popularity lies their exceptional strength-to-weight ratio and advanced corrosion resistance. FRP materials can be engineered to offer tensile strengths exceeding 240 MPa while keeping the weight at just one-quarter of steel alternatives. Furthermore, their resistance to acid, alkali, and marine atmospheres allows for extensive deployment in wastewater treatment plants, chemical facilities, offshore installations, and pedestrian bridges.

Maintenance expenses set FRP apart: a study by the American Composites Manufacturers Association showed that over a 20-year life cycle, FRP handrails incur up to 70% less maintenance cost compared to painted steel railings. UV stabilization and fire-retardant resins further enhance safety in sun-exposed and high-risk zones. Integration with FRP channel sections and frp rectangular tube reinforcements also enables load-tailored solutions (from light-duty walkways to heavy industrial access routes) through modular designs, reducing on-site installation times by up to 40%.

The versatility in coloring and texture customization not only provides aesthetic compatibility with modern architectural needs but also improves workplace safety through vivid visibility. Together, the technical attributes of frp handrails and their related components enable performance that consistently surpasses traditional handrail systems.

Manufacturer Comparison: Assessing Leading FRP Providers

As demand grows, several global manufacturers have emerged as leaders in delivering high-quality FRP handrails, frp channels, and rectangular tubes. Below is a data-driven comparison of major vendors based on essential product metrics and service parameters. This table is designed to inform purchase decisions by contrasting reliability, regional presence, customization capability, and delivery timelines.

Key Metrics Comparison Table

| Manufacturer | Mechanical Strength (MPa) | Corrosion Warranty (years) | Customization Options | Lead Time (weeks) | Global Presence |

|---|---|---|---|---|---|

| StrongRail Solutions | 245 | 15 | Handrails, Channels, Tubes (full color range) | 4-6 | North America, Europe |

| CompositeGuard Ltd. | 238 | 12 | Handrails, Rectangular Tubes | 5 | Asia-Pacific, Europe |

| PolyFiberTech | 242 | 10 | Handrails, Channels, Accessories | 3-5 | Global |

| IntegrityFRP | 230 | 8 | Custom Color Handrails | 4-8 | Americas |

The table above highlights StrongRail Solutions and PolyFiberTech as prominent players, offering broad customization and superior mechanical properties. Regional presence and lead times may vary, making it essential for project planners to evaluate based on site-specific needs and timelines.

Customized Solutions: Adapting FRP Handrails for Unique Requirements

No two infrastructure projects present identical requirements. This makes the flexibility of FRP systems, such as frp handrails, frp channel, and frp rectangular tube assemblies, especially attractive. Leading manufacturers enable engineers to specify dimensions, resin formulations, surface textures, color codes, and integrated safety features.

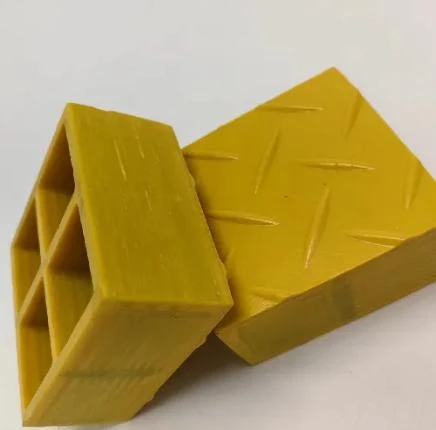

For example, FRP channels are often combined with handrail post systems to create railing layouts for non-standard walkways, while rectangular tubes offer enhanced rigidity for critical load-bearing applications. By selecting weather- and UV-resistant coatings or anti-slip surfacing, facilities managers can ensure compliance with regional safety regulations and occupational standards. Complex geometries are addressed via modular prefabrication, allowing components to be shipped flat-packed and quickly assembled on site, reducing logistical cost and installation risk.

Tailored solutions have become a norm rather than an exception, with over 65% of new industrial rail projects in North America now specifying custom FRP elements, according to the 2023 Composite Structures Market Review. The ability to match exact architectural aesthetics while achieving high performance ensures that each installation can function optimally within its intended environment and usage requirements.

Industry Applications: Proven Success Across Sectors

Versatility is a hallmark of frp handrail systems. Leading public infrastructure agencies and private companies have adopted FRP solutions for increased safety, longevity, and cost savings. The following industry case scenarios illustrate data-driven outcomes across different sectors:

Case Study Table: Real-World Impact of FRP Handrails

| Sector | Project | Solution | Key Benefit | Measured Results |

|---|---|---|---|---|

| Public Transportation | London Metro Bridge Rails | FRP handrails + Rectangular Tubes | Corrosion Resistance, Lightweight Retrofit | Reduced annual maintenance cost by 60%; 25% faster installation |

| Chemical Processing | Houston Refinery Walkways | FRP Channel-Based Rail Systems | Chemical Stability, Safety | Zero corrosion events after 8 years use |

| Marine Infrastructure | Sydney Harbor Docks | Handrails with Antislip Surface | Saltwater Durability | Life expectancy > 30 yrs; no surface degradation |

| Food Processing | Dairy Facility Catwalks | Custom Color FRP Handrails | Easy Cleaning, Hygienic Surfaces | Enhanced routine safety inspections |

This table demonstrates that FRP handrails and their components consistently deliver verified operational benefits such as drastically reduced maintenance, improved installation efficiency, and zero down-time, particularly in highly corrosive and demanding environments. Such case studies reinforce FRP solutions as the standard against traditional rail materials in critical infrastructure.

Installation and Maintenance: Ensuring Long-Term Performance

The installation process for frp handrails is engineered for efficiency. Pre-fabricated modules allow for rapid assembly, often reducing on-site labor costs by up to 30% compared to traditional steel equivalents. Lightweight sections can be handled by smaller crews, eliminating the need for heavy lifting machinery and minimizing site safety hazards.

Routine maintenance is straightforward—washing and periodic visual inspections, with no need for re-painting, rust treatments, or abrasive blasting. Fastener systems are typically corrosion-resistant alloys or composite alternatives to further assure system longevity. Available connection standards—ranging from slip-joint to mechanically fastened systems—accommodate seismic loading, thermal expansion, and heavy usage conditions.

To ensure maximum lifespan, periodic checks focus on mechanical connections and surface integrity. Since frp handrails are immune to electromagnetism, their performance is unaffected in high-voltage environments or around sensitive instrumentation, a crucial benefit for transportation, chemical, and utility sectors. These long-term performance features guarantee project security and reliable operation across decades of service.

Conclusion: The Prioritized Choice of frp handrails for Progressive Projects

Modern infrastructure projects demand resilience, cost-efficiency, and design flexibility—a trio perfectly encapsulated by frp handrails and their associated systems. The superior mechanical properties, reduced weight, and unmatched corrosion resistance not only extend service life but also ensure safety and operational efficiency in applications from coastal bridges to food plants.

Comparative data, technical innovation, and the success stories across transportation, chemical, and marine sectors make a compelling case for choosing FRP handrails over legacy materials. As regulations evolve and sustainability goals tighten, these systems’ modularity and customizable construction solidify their advantage for new builds and retrofits alike.

By embracing frp handrails, project owners and engineers position themselves at the forefront of construction technology—they safeguard their investments and align with industry trends that prioritize safety, longevity, and return on investment.

(frp handrails)

FAQS on frp handrails

Q: What are FRP handrails and where are they commonly used?

A: FRP handrails are safety railings made from fiber-reinforced plastic. They are commonly used in industrial, commercial, and marine environments due to their corrosion resistance. Their lightweight design also makes them easy to install.Q: What advantages do FRP channels provide when constructing handrails?

A: FRP channels offer high strength-to-weight ratios and excellent resistance to chemicals and weathering. These properties make them ideal for supporting and connecting handrail components. They also help extend the lifespan of handrail systems.Q: How do FRP rectangular tubes contribute to handrail systems?

A: FRP rectangular tubes serve as the main structural elements in many handrail designs. Their rigid construction and durability ensure stable and long-lasting safety barriers. They're also non-conductive and require minimal maintenance.Q: Are FRP handrails easy to install compared to metal handrails?

A: Yes, FRP handrails are lighter and can be prefabricated for quick assembly onsite. This reduces labor time and installation costs. Additionally, they do not require welding or heavy machinery.Q: How do FRP handrails perform in harsh or corrosive environments?

A: FRP handrails resist corrosion from chemicals, saltwater, and moisture significantly better than steel or aluminum. This makes them ideal for wastewater plants, marine docks, and chemical factories. Their longevity reduces long-term maintenance expenses.-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025