loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Welded Steel Bar Grating for Durable and Efficient Flooring Solutions

Understanding Welded Bar Grating Applications, Advantages, and Manufacturing

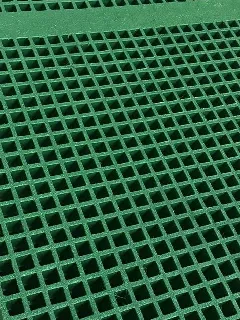

Welded bar grating is a type of industrial flooring and structural support system composed of parallel bars welded together to form a grid. It has become increasingly popular in various sectors due to its versatility, strength, and cost-effectiveness. Utilizing a systematic approach in its design and manufacture, welded bar grating serves numerous applications across multiple industries.

One of the most significant advantages of welded bar grating is its remarkable strength-to-weight ratio. This characteristic allows for the creation of robust platforms that can support heavy loads while minimizing the overall weight of the structure. This feature is particularly valuable in industries such as construction, manufacturing, and oil and gas, where heavy equipment and materials often need to be moved and stored safely.

Additionally, the open design of welded bar grating facilitates efficient drainage and ventilation. This feature makes it an ideal flooring solution for areas where spills may occur, or where debris can be washed away easily. For example, in industrial kitchens or food processing plants, welded bar grating promotes hygiene by allowing liquids and waste to flow freely underneath, reducing the risk of contamination.

Welded bar grating is also known for its durability and longevity. Constructed from materials such as steel or aluminum, it can withstand harsh environmental conditions, including exposure to chemicals, extreme temperatures, and heavy traffic. This durability not only extends the lifespan of the product but also reduces maintenance costs, making it an economical choice in the long run.

welded bar grating

The manufacturing process of welded bar grating involves several steps. First, flat bars are cut to the required lengths. Then, these bars are welded together using high-quality welding techniques to ensure structural integrity and strength. The spacing between the bars can be customized based on specific application requirements, allowing manufacturers to cater to a wide range of industrial needs. Finally, the product can be finished with anti-slip coatings or surface treatments to enhance safety and functionality.

Welded bar grating is utilized in several applications beyond flooring. Its strong and open design makes it a preferred choice for walkways, platforms, stair treads, and safety barriers. In the automotive industry, for instance, it is often used in manufacturing plants for assembly lines and workstations due to its ability to handle heavy machinery and tools. In the architectural sector, welded bar grating is used in building facades and decorative elements, providing both functionality and aesthetic appeal.

Furthermore, welded bar grating is an environmentally friendly choice. Its lightweight design reduces material usage, and many manufacturers offer options made from recycled materials. Additionally, its longevity contributes to sustainability, as fewer resources are required for replacements and repairs over time.

In conclusion, welded bar grating is a versatile and durable solution that meets the demands of various industries. Its strength, open design, and customizable nature make it an ideal choice for numerous applications, from industrial flooring to architectural features. As industries continue to seek efficient and sustainable solutions, welded bar grating will likely remain a staple in modern construction and infrastructure projects. Whether for heavy industrial use or aesthetic design, it provides a reliable and efficient flooring option that supports both safety and functionality.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025