loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

pressure vessel filter

Understanding Pressure Vessel Filters Importance, Types, and Applications

Pressure vessels are critical components in various industrial processes, serving to contain fluids (liquids and gases) at pressures significantly different from the ambient pressure. In many cases, to ensure the safe and efficient operation of these vessels, filtration systems are employed to remove impurities and particulates. Pressure vessel filters are essential in maintaining the integrity and efficiency of the system, ensuring that operations run smoothly.

Importance of Pressure Vessel Filters

The primary function of pressure vessel filters is to prevent contaminants from entering the system. Contaminants can come from several sources, including the raw materials being processed, corrosion of vessel materials, or even ingress during operation. Without effective filtration, these impurities can lead to several issues, including

1. Equipment Damage Contaminants can cause abrasion, erosion, or corrosion to the pressure vessel itself and associated piping, leading to costly repairs and downtime.

2. Operational Efficiency Filters help to maintain the flow and pressure levels necessary for optimal operation. Clogged filters can lead to decreased efficiency or even complete system failure.

3. Product Quality In processes where the end product's purity is crucial, such as in pharmaceuticals or food and beverage industries, proper filtration ensures that the final product meets quality standards.

4. Safety Pressure vessels operate under high pressure, and any failure can lead to catastrophic incidents. Filters help mitigate risks by preventing contaminants from causing pressure spikes or other irregularities.

Types of Pressure Vessel Filters

There are several types of filters used in conjunction with pressure vessels, each designed for specific applications and types of contaminants

1. Mechanical Filters These utilize physical barriers to remove particles from fluids. Common types include mesh filters and cartridge filters. Mechanical filters are straightforward and effective for removing larger particulates.

2. Magnetic Filters These filters employ magnets to attract ferrous particles from liquids. They are particularly useful in applications where metallic contaminants are a concern.

pressure vessel filter

3. Chemical Filters Chemical filtration systems use chemical reactions to remove impurities. They often involve activated carbon or other adsorbent materials to capture specific contaminants.

4. Self-Cleaning Filters These systems automate the cleaning process, allowing for continuous operation without manual intervention. This is beneficial in processes where maintaining flow is critical.

5. Hydro-Cyclones These devices separate particles from fluids based on density using centrifugal force. They are often used in applications where solid-liquid separation is needed.

Applications of Pressure Vessel Filters

Pressure vessel filters find applications across a wide range of industries, including

1. Oil and Gas In upstream and downstream operations, filters protect pumps and compressors from impurities present in crude oil and natural gas.

2. Chemical Processing In the production of various chemicals, filtration is vital to ensure product quality and protect equipment from degradation.

3. Water Treatment Pressure vessel filters are extensively used in water treatment plants to remove sediments and other pollutants, ensuring clean water supply.

4. Pharmaceuticals Maintaining the purity of products is critical in this field, making high-efficiency filters an essential component in production and packaging.

5. Food and Beverage In these industries, filters help ensure that products are free from contaminants, which is crucial for consumer safety and compliance with regulations.

Conclusion

In summary, pressure vessel filters play an indispensable role in numerous industrial applications by ensuring the purity of fluids, protecting equipment from damage, maintaining operational efficiency, and enhancing safety. With various types available, industries can select the appropriate filtration technology based on their specific needs and the nature of the contaminants encountered. As industries continue to evolve and focus on operational efficiency and product quality, the importance of effective filtration systems, such as pressure vessel filters, will only grow. By incorporating advanced filtration solutions, companies can safeguard their operations while achieving higher standards in product quality and safety.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

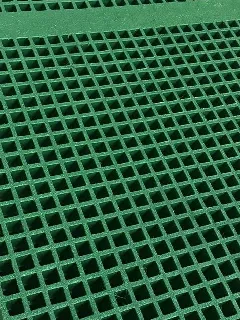

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025