loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

फेब्रुवारी . 18, 2025 05:27

Back to list

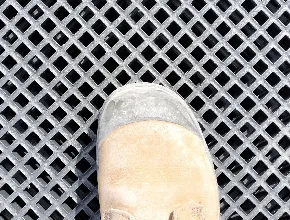

grp floor grating

Industrial settings often require exceptional durability, safety, and efficient water or debris management, and grp floor grating has emerged as an ideal solution. Glass reinforced plastic (GRP) flooring provides a robust alternative to traditional materials like wood, metal, or concrete, delivering a multitude of benefits tailored to both challenging environments and everyday applications.

For industries where cleanliness or hygiene is critical, such as food processing or pharmaceuticals, GRP floor grating offers additional benefits. Its non-porous surface does not harbor bacteria or mold, supporting clean environments and easing sanitation processes. Furthermore, its resilience to chemicals ensures that rigorous cleaning regimes do not compromise the integrity of the grating. From a sustainability perspective, GRP floor grating is also a winner. It is composed of tough, long-lasting materials that contribute to fewer replacements over time, thus minimizing waste. Additionally, some manufacturers utilize recycled materials in the production of GRP grating, supporting greener, more sustainable practices. Environmental considerations are increasingly influencing client decisions, making GRP an attractive option for businesses aiming to align with eco-friendly standards. Additionally, customization is a unique benefit offered by GRP floor grating. It can be crafted to meet specific size, color, and thickness requirements, allowing for precise conformity to project specifications. Personalized configurations enable businesses to meet aesthetic standards and functional needs simultaneously, enhancing both the operational efficiency and visual appeal of industrial settings. Professionals within engineering, construction, and industry management continuously favor GRP floor grating for these reasons, furthering its standing as an authoritative choice. As industry experts attest to its multifaceted benefits, GRP floor grating has become a trusted component of modern industrial infrastructure. In conclusion, when selecting flooring solutions in environments requiring strength, safety, cost-efficiency, and environmental consideration, GRP floor grating stands out as a comprehensive solution. Its unique properties—including corrosion resistance, non-conductive safety, light weight, and anti-slip characteristics—make it an unparalleled choice for industry professionals seeking reliability and performance. As industrial demands evolve, GRP grating continues to prove its worth through adaptability and resilience, marking it as a cornerstone product in durable infrastructure planning.

For industries where cleanliness or hygiene is critical, such as food processing or pharmaceuticals, GRP floor grating offers additional benefits. Its non-porous surface does not harbor bacteria or mold, supporting clean environments and easing sanitation processes. Furthermore, its resilience to chemicals ensures that rigorous cleaning regimes do not compromise the integrity of the grating. From a sustainability perspective, GRP floor grating is also a winner. It is composed of tough, long-lasting materials that contribute to fewer replacements over time, thus minimizing waste. Additionally, some manufacturers utilize recycled materials in the production of GRP grating, supporting greener, more sustainable practices. Environmental considerations are increasingly influencing client decisions, making GRP an attractive option for businesses aiming to align with eco-friendly standards. Additionally, customization is a unique benefit offered by GRP floor grating. It can be crafted to meet specific size, color, and thickness requirements, allowing for precise conformity to project specifications. Personalized configurations enable businesses to meet aesthetic standards and functional needs simultaneously, enhancing both the operational efficiency and visual appeal of industrial settings. Professionals within engineering, construction, and industry management continuously favor GRP floor grating for these reasons, furthering its standing as an authoritative choice. As industry experts attest to its multifaceted benefits, GRP floor grating has become a trusted component of modern industrial infrastructure. In conclusion, when selecting flooring solutions in environments requiring strength, safety, cost-efficiency, and environmental consideration, GRP floor grating stands out as a comprehensive solution. Its unique properties—including corrosion resistance, non-conductive safety, light weight, and anti-slip characteristics—make it an unparalleled choice for industry professionals seeking reliability and performance. As industrial demands evolve, GRP grating continues to prove its worth through adaptability and resilience, marking it as a cornerstone product in durable infrastructure planning.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025