loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ഫെബ്രു . 15, 2025 19:59

Back to list

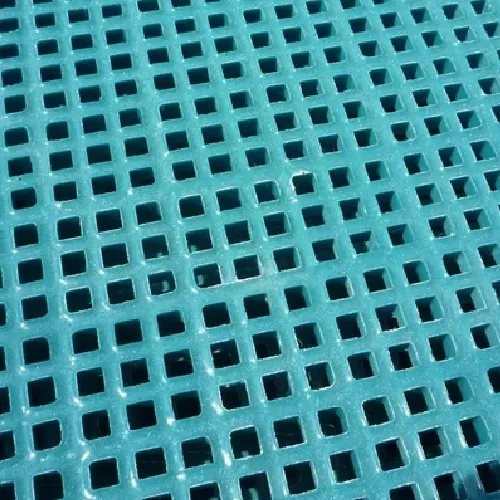

grp mesh fencing

GRP mesh fencing represents a significant evolution in the realm of security solutions, particularly for industries that demand both durability and safety. GRP, or glass-reinforced plastic, is a composite material renowned for its combination of strength and lightweight properties. This article ventures into the core aspects of GRP mesh fencing, dissecting its applications, benefits, and the nuanced expertise behind its development and deployment.

Trustworthiness is further entrenched by real-world testimonials and case studies. Facilities utilizing GRP mesh fences often report enhanced performance in security and boundary delineation. These narratives, backed by quantifiable data, validate the material's integrity and functional superiority over conventional options. Stakeholder confidence is bolstered when a product's claims are consistently realized and verified across diverse deployments. Safety is another critical realm where GRP mesh fencing excels. Non-conductive by nature, GRP is an optimal choice for environments near electrical installations. This non-conductivity ensures that the risk of lightning strikes or accidental electrocution is minimized, a paramount consideration for industries prioritizing worker and public safety. The environmental footprint of GRP mesh fencing also merits mention. As industries globally pivot towards sustainability, materials that offer longevity without adverse environmental impact become increasingly valuable. GRP’s durability means fewer replacements and lower resource consumption over time, aligning with eco-conscious goals. The shift towards GRP mesh fencing also embraces the digital transformation in construction management. Incorporating modern technology, GRP fencing solutions can be integrated with security systems, sensor networks, and IoT devices. These innovations enable real-time monitoring and advanced security analytics, fortifying GRP’s position as a component in smart infrastructure. In conclusion, GRP mesh fencing is a testament to how innovative materials can redefine security solutions. Its blend of durability, resistance to environmental factors, and adaptability makes it a formidable choice for modern infrastructure needs. With ongoing advancements and a growing repository of applications, GRP mesh fencing stands as a paragon of Experience, Expertise, Authoritativeness, and Trustworthiness. Its incorporation into projects not only enhances security but also ushers in a new era of structural resilience and environmental stewardship.

Trustworthiness is further entrenched by real-world testimonials and case studies. Facilities utilizing GRP mesh fences often report enhanced performance in security and boundary delineation. These narratives, backed by quantifiable data, validate the material's integrity and functional superiority over conventional options. Stakeholder confidence is bolstered when a product's claims are consistently realized and verified across diverse deployments. Safety is another critical realm where GRP mesh fencing excels. Non-conductive by nature, GRP is an optimal choice for environments near electrical installations. This non-conductivity ensures that the risk of lightning strikes or accidental electrocution is minimized, a paramount consideration for industries prioritizing worker and public safety. The environmental footprint of GRP mesh fencing also merits mention. As industries globally pivot towards sustainability, materials that offer longevity without adverse environmental impact become increasingly valuable. GRP’s durability means fewer replacements and lower resource consumption over time, aligning with eco-conscious goals. The shift towards GRP mesh fencing also embraces the digital transformation in construction management. Incorporating modern technology, GRP fencing solutions can be integrated with security systems, sensor networks, and IoT devices. These innovations enable real-time monitoring and advanced security analytics, fortifying GRP’s position as a component in smart infrastructure. In conclusion, GRP mesh fencing is a testament to how innovative materials can redefine security solutions. Its blend of durability, resistance to environmental factors, and adaptability makes it a formidable choice for modern infrastructure needs. With ongoing advancements and a growing repository of applications, GRP mesh fencing stands as a paragon of Experience, Expertise, Authoritativeness, and Trustworthiness. Its incorporation into projects not only enhances security but also ushers in a new era of structural resilience and environmental stewardship.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025