loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

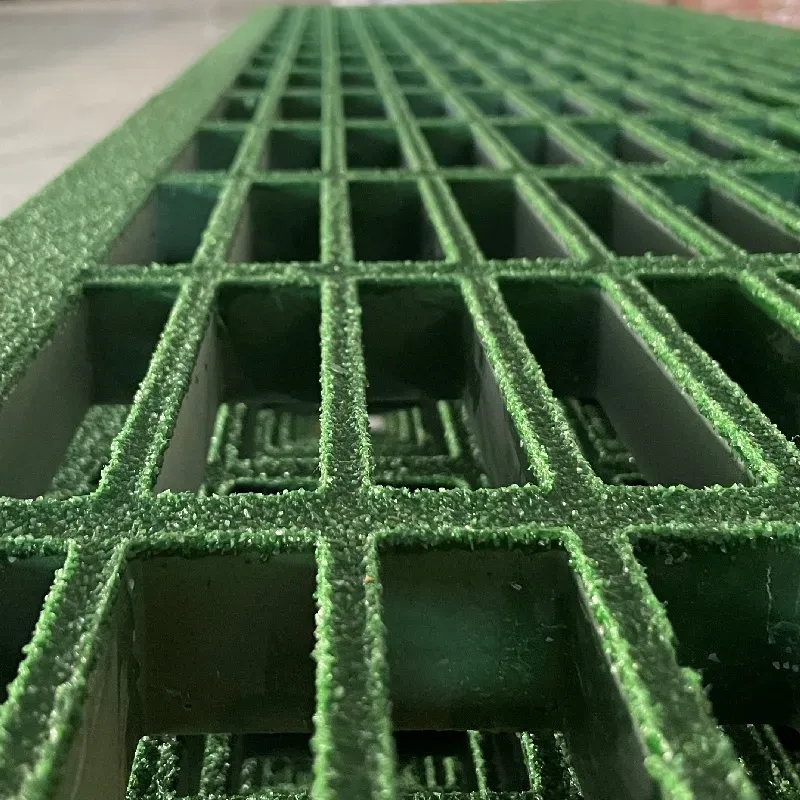

frp micro mesh grating

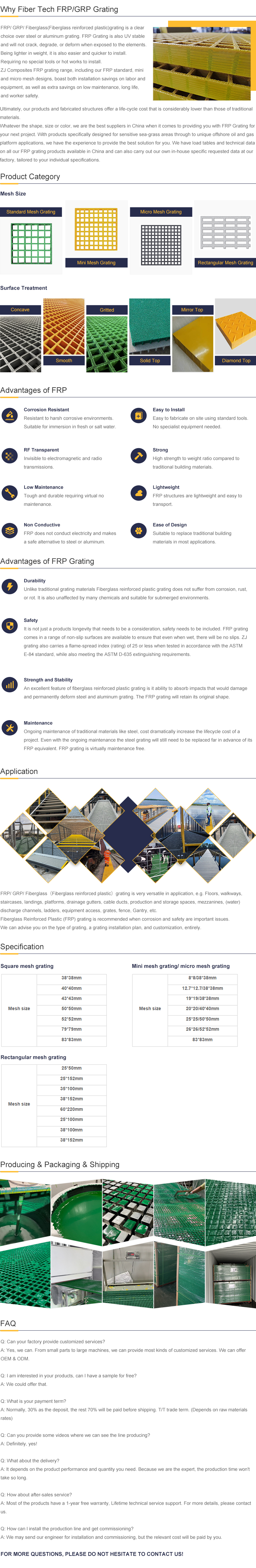

Fiber Reinforced Plastic (FRP) grating has emerged as an exceptional alternative to traditional materials used in various industries such as construction, marine, and chemical processing. With evolving technological advancements, the demand for FRP grating has surged, primarily due to its superiority in terms of strength, durability, and resistance to environmental factors.

One of the most significant advantages of FRP grating is its corrosion resistance. Unlike metal grating, which may succumb to rust and deterioration over time, FRP grating maintains its integrity even when exposed to harsh chemicals and corrosive environments. This property makes it an ideal choice for industries with exposure to saltwater or corrosive substances, ensuring long-term reliability and reducing maintenance costs.

FRP grating is also renowned for its lightweight nature. This feature not only makes it easy to install but also reduces transportation costs. The reduced weight does not compromise its load-bearing capacity, which remains comparable to, or even exceeding, that of traditional steel grating. As a result, structures utilizing FRP grating benefit from enhanced safety and reliability without the added burden of excess weight.

Safety is further enhanced by the excellent anti-slip properties of FRP grating. In industries where the risk of slipping is high due to wet or oily surfaces, FRP grating's slip-resistant surface provides an added layer of protection. This is particularly crucial in workplace environments where ensuring employee safety is a top priority.

Customization is another hallmark of FRP grating. It is available in various sizes, shapes, and colors, allowing for tailored solutions to meet specific project needs. The ability to customize not only aids in aesthetic appeal but also enhances functionality according to distinct requirements of different projects.

grating frp

From an environmental perspective, FRP grating presents a sustainable choice. The production process of FRP involves using materials that can be recycled, reducing the overall environmental footprint. This aligns with the growing global emphasis on sustainable development and resource conservation.

Despite the apparent benefits, the initial cost of FRP grating can be higher compared to traditional materials. However, considering its longevity, reduced maintenance needs, and superior performance, the return on investment for FRP grating is significant over time. Companies and industries that have adopted FRP grating report lower long-term costs and increased productivity, making it a cost-effective solution in the grand scheme of project management.

It is also noteworthy that the installation of FRP grating does not require welding or hot works, further reducing the risk of onsite accidents and ensuring compliance with stringent safety regulations. This feature emphasizes the user-friendly aspect of FRP grating, making it a preferred choice for project managers aiming for swift and safe construction practices.

In summary, FRP grating brings together the best of technological advancement and practical application. Its unparalleled strength, resistance to adverse conditions, and adaptability make it a premium choice for industries aiming for longevity, safety, and cost-effectiveness. As industries continue to evolve with a focus on efficiency and sustainability, FRP grating stands out as a material that not only meets but exceeds these burgeoning expectations.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025