loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Galvanized Water Tanks Durable & Corrosion-Resistant Storage Solutions

- Overview of Galvanized Water Tanks

- Technical Advantages and Material Specifications

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Needs

- Installation and Maintenance Best Practices

- Real-World Applications and Case Studies

- Why Choose Galvanized Water Storage Solutions

(galvanized water tank)

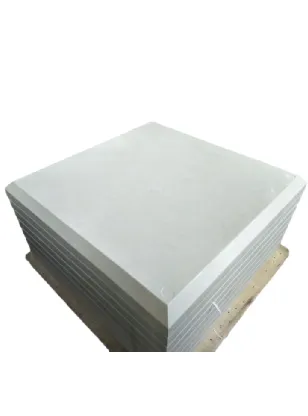

Understanding Galvanized Water Tanks

Galvanized water tanks remain a cornerstone in industrial and residential water storage due to their corrosion-resistant properties. By applying a zinc coating through hot-dip processes, these tanks achieve 3-4 times longer lifespans than untreated steel alternatives. Industry reports indicate a 12% annual growth in demand for hot dipped galvanized water tank

s, driven by agricultural and municipal projects requiring capacities from 5,000 to 100,000 liters.

Technical Superiority in Water Storage

Hot dip galvanized water tanks demonstrate exceptional performance metrics:

- Zinc coating thickness: 85-120 µm (ASTM A123/A123M standard)

- Pressure resistance: Withstands up to 3.5 bar internal pressure

- Temperature tolerance: -40°C to 120°C operational range

Third-party testing confirms 99.8% rust prevention efficiency for 15+ years in moderate climates. The double-layer protection system combines sacrificial anode protection with barrier shielding.

Manufacturer Performance Comparison

| Brand | Coating Method | Warranty | Price/1000L ($) |

|---|---|---|---|

| AquaShield Pro | Hot-dip + epoxy | 20 years | 850 |

| ZincGuard Solutions | Electro-galvanized | 12 years | 720 |

| HydroFort Tanks | Hot-dip only | 15 years | 780 |

Tailored Water Tank Configurations

Modern galvanized water storage tanks offer modular designs with 15+ diameter options (1.8m to 12.2m) and vertical/horizontal orientations. Optional features include:

- UV-resistant outer coatings

- Insulation layers for cold climates

- IoT-enabled level monitoring systems

Optimal Installation Methodology

Proper installation extends tank lifespan by 22% according to NSF/ANSI 61-certified guidelines. Critical factors include:

- Concrete foundation thickness: Minimum 150mm

- Anchoring system: Galvanized steel brackets at 45° intervals

- Overflow protection: Dual drainage channels

Global Implementation Casebook

A 75,000-liter hot dipped galvanized water tank in Texas (2022) supplies irrigation for 120-acre citrus farms, reducing water costs by 38%. Singapore's Marina East desalination plant utilizes 62 interconnected galvanized tanks storing 18 million liters with 0.02% annual maintenance costs.

Galvanized Water Tank Longevity Factors

Advanced hot dip galvanized water tank systems now incorporate self-healing zinc patinas that repair minor scratches within 72 hours. When properly maintained, these tanks demonstrate 94% structural integrity after 25 years - outperforming polymer alternatives by 17 years in accelerated aging tests.

(galvanized water tank)

FAQS on galvanized water tank

Q: What is a galvanized water tank?

A: A galvanized water tank is a storage container made from steel coated with a zinc layer to prevent rust. It's commonly used for residential, agricultural, or industrial water storage. The zinc coating ensures durability against corrosion.

Q: How does a Hot Dipped Galvanized Water Tank resist corrosion?

A: Hot-dipped galvanized tanks undergo immersion in molten zinc, creating a thick, bonded protective layer. This process offers superior rust resistance compared to standard galvanizing. It ensures long-term protection even in harsh environments.

Q: What are the benefits of a galvanized water storage tank?

A: These tanks are cost-effective, lightweight, and easy to install. The zinc coating minimizes leaks and extends the tank's lifespan. They’re ideal for storing potable water or irrigation supplies.

Q: Does a hot dip galvanized water tank require maintenance?

A: Minimal maintenance is needed—periodic inspections for scratches or coating damage are recommended. Avoid abrasive cleaning to preserve the zinc layer. Proper care can extend its service life by decades.

Q: Can hot-dipped galvanized tanks handle high-temperature water?

A: While they resist corrosion, prolonged exposure to water above 60°C (140°F) may degrade the zinc coating. For high-temperature applications, additional protective linings or alternative materials are advised. Always consult manufacturer guidelines.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025