loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ജനു . 26, 2025 08:31

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

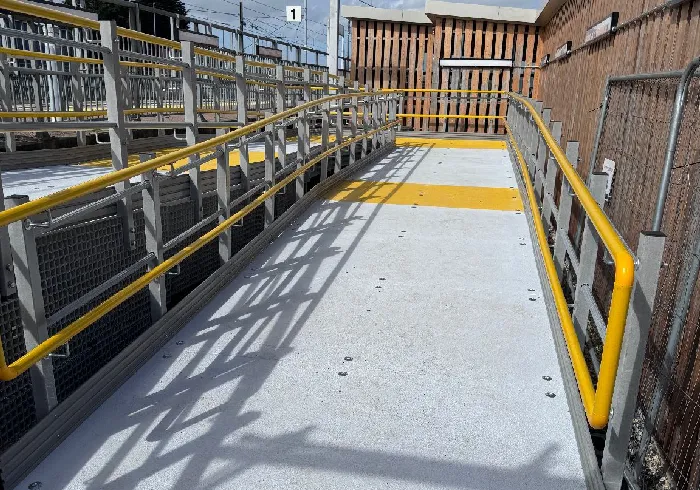

Fiberglass Reinforced Polymer (FRP) sheet piling is revolutionizing the way modern construction projects address issues of erosion control, flood management, and soil reinforcement. Predominantly employed in marine environments due to its resistance to water corrosion, this advanced material offers a plethora of benefits that traditional materials like steel or wood cannot match.

Trustworthiness is a critical factor in any construction project, and FRP sheet piling delivers peace of mind with its eco-friendly profile. Made from composite materials, FRP is non-toxic and does not leach harmful substances into the surrounding soil or water. Environmental engineers advocate for its use in sensitive ecological zones, emphasizing that it provides stability without compromising the local ecosystem. The recyclability of FRP also contributes to its positive environmental impact, appealing to projects with sustainability mandates. Testimonials from project managers in environmentally sensitive regions corroborate the material’s minimal ecological footprint, while still providing the necessary infrastructural support. Furthermore, case studies document the successful deployment of FRP sheet piling in various infrastructural projects worldwide, ranging from waterfront remediation in coastal cities to levee reinforcements in flood-prone areas. These real-world applications validate its efficacy and versatility. For instance, a significant riverbank restoration project in Europe successfully utilized FRP sheet piling to stabilize the banks, resulting in a marked reduction in erosion while enhancing the area’s natural aesthetics. In conclusion, the integration of FRP sheet piling into construction practices is not merely a trend but an evolution driven by tangible benefits and scientific validation. Construction experts and environmental advocates alike support this material’s adoption, underscoring its resilience, cost-effectiveness, and environmental harmony. As more data from ongoing projects becomes available, the case for FRP continues to strengthen, paving the way for its future in sustainable construction and environmental preservation.

Trustworthiness is a critical factor in any construction project, and FRP sheet piling delivers peace of mind with its eco-friendly profile. Made from composite materials, FRP is non-toxic and does not leach harmful substances into the surrounding soil or water. Environmental engineers advocate for its use in sensitive ecological zones, emphasizing that it provides stability without compromising the local ecosystem. The recyclability of FRP also contributes to its positive environmental impact, appealing to projects with sustainability mandates. Testimonials from project managers in environmentally sensitive regions corroborate the material’s minimal ecological footprint, while still providing the necessary infrastructural support. Furthermore, case studies document the successful deployment of FRP sheet piling in various infrastructural projects worldwide, ranging from waterfront remediation in coastal cities to levee reinforcements in flood-prone areas. These real-world applications validate its efficacy and versatility. For instance, a significant riverbank restoration project in Europe successfully utilized FRP sheet piling to stabilize the banks, resulting in a marked reduction in erosion while enhancing the area’s natural aesthetics. In conclusion, the integration of FRP sheet piling into construction practices is not merely a trend but an evolution driven by tangible benefits and scientific validation. Construction experts and environmental advocates alike support this material’s adoption, underscoring its resilience, cost-effectiveness, and environmental harmony. As more data from ongoing projects becomes available, the case for FRP continues to strengthen, paving the way for its future in sustainable construction and environmental preservation.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

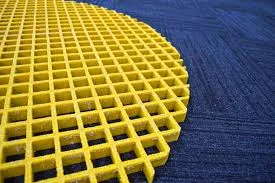

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025