loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

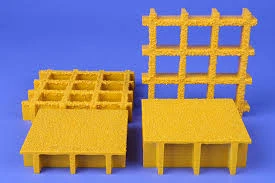

High-Quality FRP Grating Available for Purchase at Competitive Prices

Understanding FRP Grating A Comprehensive Guide

FRP grating, or Fibre Reinforced Polymer grating, is quickly gaining popularity in various industrial applications due to its numerous advantages over traditional materials. With its lightweight composition, corrosion resistance, and high strength-to-weight ratio, FRP grating presents a compelling choice for many projects. If you’re considering purchasing FRP grating, this guide will help you understand its benefits, applications, and what to look for when searching for FRP grating for sale.

What is FRP Grating?

FRP grating consists of a composite material made up of a polymer matrix reinforced with fiberglass. This combination results in a non-corrosive, robust structure ideal for environments prone to moisture, chemicals, and extreme temperatures. Unlike conventional steel or aluminum grating, FRP grating does not require additional coatings or treatments to withstand harsh conditions, making it a cost-effective and low-maintenance option.

Key Benefits of FRP Grating

1. Corrosion Resistance One of the standout features of FRP grating is its exceptional corrosion resistance. This property makes it ideal for use in chemical processing plants, wastewater facilities, and marine environments, where exposure to harsh chemicals and salts is common.

2. Lightweight FRP grating is significantly lighter than metal alternatives, which simplifies installation processes and reduces transportation costs. Its lightweight nature allows for easier handling without compromising structural integrity.

3. High Strength-to-Weight Ratio FRP grating provides remarkable strength while maintaining a light profile, which is beneficial in applications where both durability and weight constraints are critical.

4. Non-Conductive For facilities handling electrical wiring or equipment, the non-conductive nature of FRP grating offers an added layer of safety and minimizes the risk of electric shock.

5. Versatile Applications From industrial flooring and walkways to platforms and stair treads, FRP grating can be utilized in various settings, including power plants, oil rigs, pulp and paper factories, and more.

frp grating for sale

Factors to Consider When Purchasing FRP Grating

When searching for FRP grating for sale, it's essential to consider several factors to ensure you make an informed choice

1. Load-Bearing Capacity Understand the load requirements for your project to select the appropriate thickness and support structure for the grating. Different applications demand varying load capacities.

2. Chemical Resistance Depending on the environment in which the grating will be used, it's vital to know how well the grating can withstand specific chemicals. Check with the manufacturer regarding the grating's resistance to particular substances.

3. UV Stability If the grating will be outdoors, ensure that it has sufficient UV stabilizers to prevent degradation and maintain color stability over time.

4. Compliance and Standards Look for FRP grating that meets industry standards and regulations relevant to your application. Compliance ensures safety, durability, and performance.

5. Supplier Reputation Choose a reputable supplier with positive reviews and testimonials. A trustworthy supplier will provide quality products and reliable customer service, assisting with any inquiries or issues that may arise.

Conclusion

FRP grating represents an innovative solution for many industries, combining durability with significant advantages over traditional materials. As you search for FRP grating for sale, focus on understanding your specific needs and the factors mentioned above to ensure you procure the right product for your application. Investing in quality FRP grating not only enhances safety and performance but also proves to be a cost-effective solution in the long run. As this material continues to reshape various sectors, keep an eye out for emerging technologies and improvements in FRP offerings to stay ahead in your industry.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025