loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

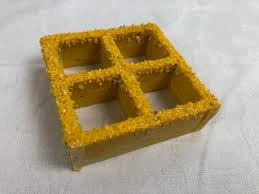

fibreglass grating price

Understanding Fiberglass Grating Prices Key Factors and Insights

Fiberglass grating has become a popular choice in various industries, including construction, chemical processing, and wastewater treatment. It offers a lightweight alternative to traditional steel and aluminum grating, providing durability and resistance to corrosion and chemical exposure. However, potential buyers often find themselves asking a crucial question how much should they expect to spend on fiberglass grating? In this article, we will explore the factors influencing fiberglass grating prices and help you understand what you can expect in terms of cost.

1. Material Quality

The price of fiberglass grating varies significantly based on the quality of materials used in its production. High-quality fiberglass composites that are resistant to UV radiation, chemicals, and high temperatures tend to be more expensive. When selecting fiberglass grating for specific applications, it's important to consider the environment in which it will be used. Investing in higher-quality materials may lead to lower maintenance costs and a longer lifespan, ultimately providing better value for money.

There are several types of fiberglass grating available, including pultruded, molded, and custom designs. Pultruded grating typically offers the highest strength-to-weight ratio and is often used in heavy-load applications. Molded grating, on the other hand, is generally more economical and is ideal for lighter applications. Custom designs, though tailored to specific needs, can increase production costs, impacting the overall price significantly.

3. Size and Thickness

The dimensions of the fiberglass grating, including its width, length, and thickness, also play a crucial role in determining its price. Larger panels and thicker grating sections typically cost more due to the increased material usage. Buyers should carefully evaluate the size requirements of their project to avoid unnecessary expenses on oversized or excessively thick grating when a standard size would suffice.

4. Load Capacity

fibreglass grating price

Load capacity is another essential factor affecting fiberglass grating prices. Grating designed for high load-bearing applications will generally cost more than those meant for lighter loads. Understanding the anticipated load requirements is vital in selecting the right grating type and construction, ensuring safety and compliance with industry standards without overspending.

5. Surface Finish

The surface finish of fiberglass grating can influence the price as well. Options such as textured surfaces for slip resistance or smooth finishes for clean environments have different costs associated with them. Depending on the intended use, you may find it beneficial to invest in a particular surface finish that enhances safety or meets specific regulatory requirements.

6. Manufacturing Process

Different manufacturing processes can yield variations in pricing. For instance, molded grating is produced by combining resin and glass fibers in a mold, while pultruded grating is created by pulling the composite materials through a heated die. Each method has its own cost implications, affecting both the performance characteristics and the final price of the product.

7. Supplier and Market Conditions

Lastly, pricing may vary depending on the supplier and the prevailing market conditions. Competitive bids from multiple suppliers can lead to better pricing options, while market fluctuations in raw materials can drive prices up or down. Thus, it is wise to compare offers from various suppliers while considering quality, warranty, and after-sale support.

Conclusion

The price of fiberglass grating is influenced by multiple factors, including material quality, type, size, load capacity, surface finish, manufacturing process, and supplier dynamics. To make an informed purchasing decision, it is imperative to assess your specific needs and budget while considering the long-term advantages of investing in quality fiberglass grating. Always obtain quotes from reputable suppliers, compare them thoroughly, and consider the overall value rather than focusing solely on the initial price tag. By doing so, you can ensure that you select the right fiberglass grating solution for your specific application, leading to enhanced safety, durability, and performance in the long run.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025