loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ജനു . 22, 2025 01:43

Back to list

fiberglass water storage tank

Fiberglass water storage tanks are rapidly becoming the preferred choice for both residential and industrial applications due to their unique combination of durability, efficiency, and adaptability. Drawing upon years of expertise in the field of water storage solutions, this in-depth examination will highlight the reasons behind their increasing popularity and affirm their credibility as a reliable investment.

In terms of expertise, manufacturers of fiberglass water storage tanks employ advanced engineering techniques and high-quality materials to ensure optimal performance and safety. Rigorous testing procedures are conducted to comply with international standards, a testament to the tanks' robustness and reliability. Insights from industry-leading engineers reveal that the unique properties of fiberglass allow for superior structural integrity, even under high-pressure and variable temperature conditions. This aspect is critical for industries that require dependable and stable water supply systems. The customizability of fiberglass tanks is another noteworthy feature. End-users can choose from a variety of tank sizes and configurations, tailoring solutions to specific needs, whether for agricultural irrigation, fire protection systems, or potable water storage. Many urban planners and architects advocate for their use when space constraints are an issue, as the tanks can be discreetly integrated without compromising capacity or functionality. Regarding trustworthiness, companies specializing in fiberglass water storage solutions are known for their commitment to quality assurance. Industry certifications and accreditation from standard bodies such as ISO certify the reliability of these products. Furthermore, customers consistently express high levels of satisfaction and confidence in the resilience and effectiveness of their fiberglass water storage systems. User testimonials frequently highlight consistent performance, low maintenance requirements, and excellent service from suppliers. In summary, fiberglass water storage tanks emerge as a superior option for modern needs with their unmatched durability, flexibility, and environmental advantages. Proven through industry expertise and evidenced by user satisfaction, these tanks stand as authoritative and trustworthy solutions, poised to meet the demands of diverse applications while ensuring peace of mind for those who choose to invest in them.

In terms of expertise, manufacturers of fiberglass water storage tanks employ advanced engineering techniques and high-quality materials to ensure optimal performance and safety. Rigorous testing procedures are conducted to comply with international standards, a testament to the tanks' robustness and reliability. Insights from industry-leading engineers reveal that the unique properties of fiberglass allow for superior structural integrity, even under high-pressure and variable temperature conditions. This aspect is critical for industries that require dependable and stable water supply systems. The customizability of fiberglass tanks is another noteworthy feature. End-users can choose from a variety of tank sizes and configurations, tailoring solutions to specific needs, whether for agricultural irrigation, fire protection systems, or potable water storage. Many urban planners and architects advocate for their use when space constraints are an issue, as the tanks can be discreetly integrated without compromising capacity or functionality. Regarding trustworthiness, companies specializing in fiberglass water storage solutions are known for their commitment to quality assurance. Industry certifications and accreditation from standard bodies such as ISO certify the reliability of these products. Furthermore, customers consistently express high levels of satisfaction and confidence in the resilience and effectiveness of their fiberglass water storage systems. User testimonials frequently highlight consistent performance, low maintenance requirements, and excellent service from suppliers. In summary, fiberglass water storage tanks emerge as a superior option for modern needs with their unmatched durability, flexibility, and environmental advantages. Proven through industry expertise and evidenced by user satisfaction, these tanks stand as authoritative and trustworthy solutions, poised to meet the demands of diverse applications while ensuring peace of mind for those who choose to invest in them.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

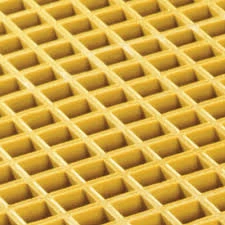

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025