loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ജനു . 26, 2025 06:33

Back to list

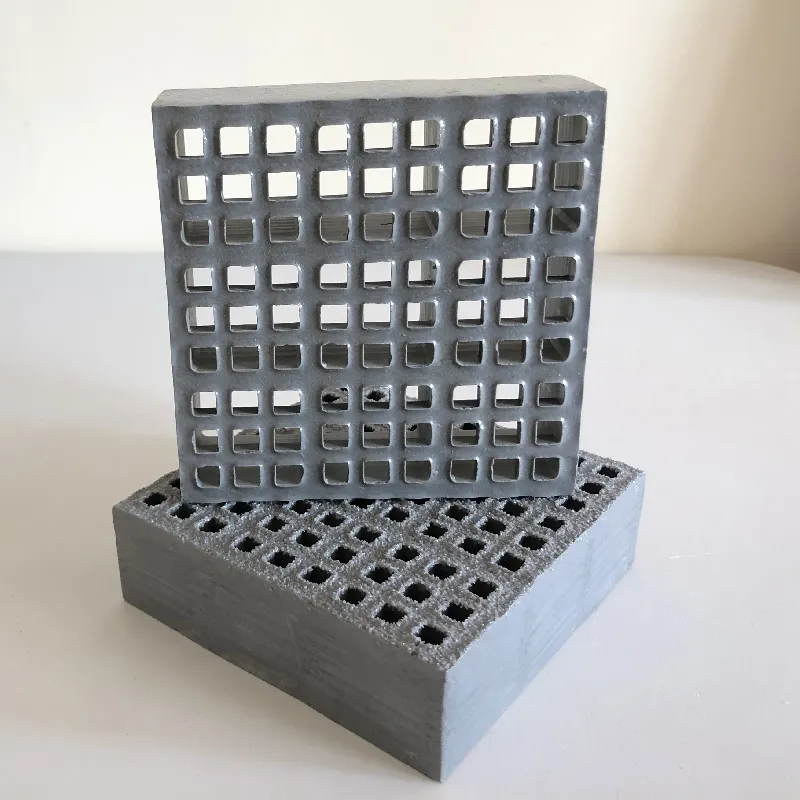

frp micro mesh grating

In today's rapidly evolving construction landscape, fiberglass rebar stands out as a groundbreaking alternative to traditional steel reinforcement. As industries increasingly seek solutions that offer durability, resilience, and cost-effectiveness, fiberglass rebar has become a focal point of discussion among architects, engineers, and builders. This article delves into the unique aspects of fiberglass rebar, offering insights with an emphasis on experience, expertise, authoritativeness, and trustworthiness.

The production processes involved in fiberglass rebar manufacturing incorporate the latest technological advancements. Using a composite of glass fibers and resin, manufacturers achieve a precise alignment that enhances the mechanical properties of the rebar. This meticulous attention to detail underscores the expertise involved in transforming raw materials into a finished product capable of withstanding infrastructural demands. Professionals experienced in large-scale construction projects find that fiberglass rebar offers unparalleled versatility. Its application transcends traditional boundaries, adapting seamlessly to both conventional and cutting-edge designs. Whether used in residential projects or commercial megastructures, fiberglass rebar proves beneficial not only in terms of construction efficiency but also in its contribution to sustainable building practices. The market for fiberglass rebar continues to grow as manufacturers innovate and refine production techniques. By leveraging automated machinery and emphasizing quality control at every stage of production, manufacturers ensure that each piece of rebar meets the high expectations of today's construction stakeholders. Importantly, this focus on quality does not compromise the economic feasibility of using fiberglass rebar, which remains a cost-effective alternative to traditional materials. In conclusion, fiberglass rebar embodies the future of construction materials through its superior attributes and positive impact on the industry's sustainability goals. As more manufacturers invest in research and development to enhance these materials further, the construction sector is poised to benefit immensely, adopting more resilient, durable, and eco-friendly solutions. The body of evidence supporting the use of fiberglass rebar continues to grow, solidifying its reputation as a trusted and innovative component of modern infrastructure.

The production processes involved in fiberglass rebar manufacturing incorporate the latest technological advancements. Using a composite of glass fibers and resin, manufacturers achieve a precise alignment that enhances the mechanical properties of the rebar. This meticulous attention to detail underscores the expertise involved in transforming raw materials into a finished product capable of withstanding infrastructural demands. Professionals experienced in large-scale construction projects find that fiberglass rebar offers unparalleled versatility. Its application transcends traditional boundaries, adapting seamlessly to both conventional and cutting-edge designs. Whether used in residential projects or commercial megastructures, fiberglass rebar proves beneficial not only in terms of construction efficiency but also in its contribution to sustainable building practices. The market for fiberglass rebar continues to grow as manufacturers innovate and refine production techniques. By leveraging automated machinery and emphasizing quality control at every stage of production, manufacturers ensure that each piece of rebar meets the high expectations of today's construction stakeholders. Importantly, this focus on quality does not compromise the economic feasibility of using fiberglass rebar, which remains a cost-effective alternative to traditional materials. In conclusion, fiberglass rebar embodies the future of construction materials through its superior attributes and positive impact on the industry's sustainability goals. As more manufacturers invest in research and development to enhance these materials further, the construction sector is poised to benefit immensely, adopting more resilient, durable, and eco-friendly solutions. The body of evidence supporting the use of fiberglass rebar continues to grow, solidifying its reputation as a trusted and innovative component of modern infrastructure.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025