loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 14, 2025 12:28

Back to list

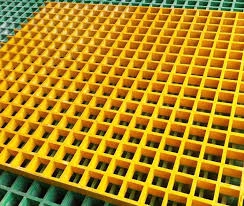

anti slip grating

Navigating industrial environments safely often hinges on one critical component anti-slip grating. This essential material is specifically designed to address the perennial safety challenges posed by slippery surfaces, whether due to water, oil, or other hazardous substances. The need for secure footing is a non-negotiable in industries ranging from oil and gas to construction and manufacturing.

Trust in anti-slip grating is underscored by third-party certifications and testing. Many manufacturers subject their products to stringent testing procedures, ensuring they meet and exceed industry standards for safety. This commitment to excellence is foundational, as trustworthiness in safety equipment can make all the difference between a secure workplace and one that is fraught with risk. Furthermore, user testimonials and long-term usage data highlight the reliability and efficacy of anti-slip solutions across various applications. Incorporating anti-slip grating into facility design is not merely a compliance measure; it is a strategic investment in safety. Facilities that prioritize this can expect not only enhanced safety metrics but also improved employee morale and productivity, as workers are more comfortable and secure in their environment. The true value of anti-slip grating is realized not just in its immediate utility, but in its enduring contribution to a culture of safety, underscoring its essential role in modern industrial design. In conclusion, the implementation of anti-slip grating is a testament to a facility's commitment to safety, reflecting a proactive stance on risk management. Its proven effectiveness, backed by expert analysis and industry endorsement, marks it as an indispensable component in safety strategy. As industries evolve and safety standards become ever more stringent, the demand for reliable, tested solutions like anti-slip grating will undoubtedly continue to rise.

Trust in anti-slip grating is underscored by third-party certifications and testing. Many manufacturers subject their products to stringent testing procedures, ensuring they meet and exceed industry standards for safety. This commitment to excellence is foundational, as trustworthiness in safety equipment can make all the difference between a secure workplace and one that is fraught with risk. Furthermore, user testimonials and long-term usage data highlight the reliability and efficacy of anti-slip solutions across various applications. Incorporating anti-slip grating into facility design is not merely a compliance measure; it is a strategic investment in safety. Facilities that prioritize this can expect not only enhanced safety metrics but also improved employee morale and productivity, as workers are more comfortable and secure in their environment. The true value of anti-slip grating is realized not just in its immediate utility, but in its enduring contribution to a culture of safety, underscoring its essential role in modern industrial design. In conclusion, the implementation of anti-slip grating is a testament to a facility's commitment to safety, reflecting a proactive stance on risk management. Its proven effectiveness, backed by expert analysis and industry endorsement, marks it as an indispensable component in safety strategy. As industries evolve and safety standards become ever more stringent, the demand for reliable, tested solutions like anti-slip grating will undoubtedly continue to rise.

Share

Next:

Latest news

-

Why FRP Grating Panels are the Best Choice for Your Industrial NeedsNewsMay.09,2025

-

He Versatility and Strength of Mini Mesh Grating for Your ProjectsNewsMay.09,2025

-

The Durability and Versatility of FRP Profiles and Pultruded SectionsNewsMay.09,2025

-

The Advantages of Sectional Tanks for Efficient Water StorageNewsMay.09,2025

-

he Advantage of FRP Pressure Tanks and Pressure VesselsNewsMay.09,2025

-

Maximize Safety and Durability with Covered Grating SolutionsNewsMay.09,2025

-

Understanding SMC Panel TanksNewsApr.21,2025