loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

vessel purifier

The Importance of Vessel Purifiers in Modern Maritime Operations

In the ever-evolving world of maritime operations, environmental regulations and technological advancements have come to the forefront of vessel management practices. One of the key components in maintaining compliance with both local and international environmental standards is the vessel purifier. These systems play a crucial role in ensuring the safe and efficient operation of ships by managing and treating the waste generated during maritime activities.

What is a Vessel Purifier?

A vessel purifier, commonly known as an oil-water separator, is an essential piece of equipment designed to remove impurities from fuel or oily water before it is discharged or reused. This equipment is particularly significant in the context of the shipping industry, where vessels are often required to adhere to strict regulations set forth by organizations such as the International Maritime Organization (IMO). These regulations aim to mitigate the impact of marine pollution, primarily focusing on the discharge of oil into the sea.

The Need for Purifiers

The maritime industry faces continuous pressure to reduce its carbon footprint and minimize its environmental impact. Oil spills and discharges not only harm marine ecosystems but can also result in hefty fines and damage to a company's reputation. By employing effective vessel purifiers, shipping companies can comply with international standards, promoting sustainability and environmental responsibility.

Purifiers work by utilizing a combination of physical and chemical processes to separate oil from water. The process typically involves the following stages

1. Pre-Treatment Before the main separation process occurs, incoming water is pre-treated to remove larger particles and sediments that could hinder the efficiency of the purifier.

2. Separation The heart of vessel purifiers, this stage involves the use of gravity and centrifugal forces to separate oil from water. The cleaned water can then either be discharged overboard (if it meets the necessary standards) or sent for further treatment.

3. Post-Treatment After the oil-water mixture has been processed, any remaining contaminants are further treated to ensure compliance with discharge regulations.

vessel purifier

Advancements in Purifier Technology

The evolution of vessel purifiers has been marked by a shift toward more advanced, automated systems. These newer technologies often incorporate monitoring systems that can provide real-time data about the efficiency and effectiveness of the purification process. Advanced purifiers can now adapt to varying operational conditions and are equipped with features that enhance their performance, making them more efficient and reliable.

Moreover, environmental benefits are not limited to oil separation. Many modern purifiers can also handle bilge water treatment, which significantly reduces the total volume of waste that needs to be disposed of. As a result, vessels equipped with sophisticated purifiers contribute to a cleaner marine environment.

Regulatory Compliance and Best Practices

To ensure the effective operation of vessel purifiers, shipping companies need to stay informed about changing regulations and best practices. This includes regular maintenance and calibration of the purification systems, thorough training for crew members on operation and emergency protocols, and comprehensive record-keeping for compliance audits.

Additionally, companies should consider integrating purifiers with other pollution prevention technologies, such as exhaust gas cleaning systems and ballast water treatment systems, to create a holistic approach to environmental management in maritime operations.

Conclusion

The vessel purifier is an indispensable tool in the contemporary shipping industry, serving not only to comply with environmental regulations but also to foster a culture of sustainability. As the maritime sector continues to grow and evolve, the significance of effective waste treatment solutions cannot be overstated. By investing in advanced purification technologies and adhering to best practices, shipping companies can position themselves as leaders in environmental stewardship while ensuring the longevity of our oceans.

In conclusion, the vessel purifier is more than just a piece of machinery; it is a crucial component in maintaining the delicate balance between maritime operations and environmental conservation. The future of shipping depends on our commitment to developing and adopting cleaner technologies capable of preserving the marine ecosystem for future generations.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

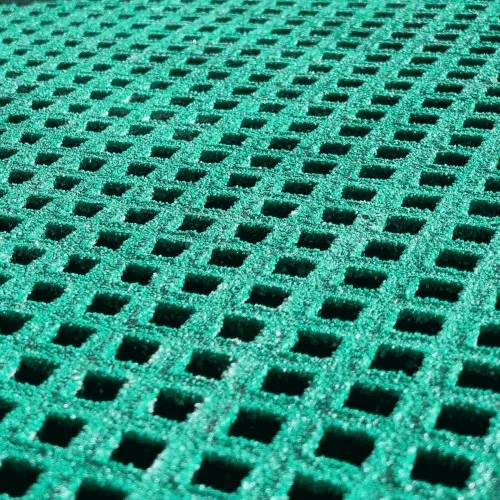

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025