loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

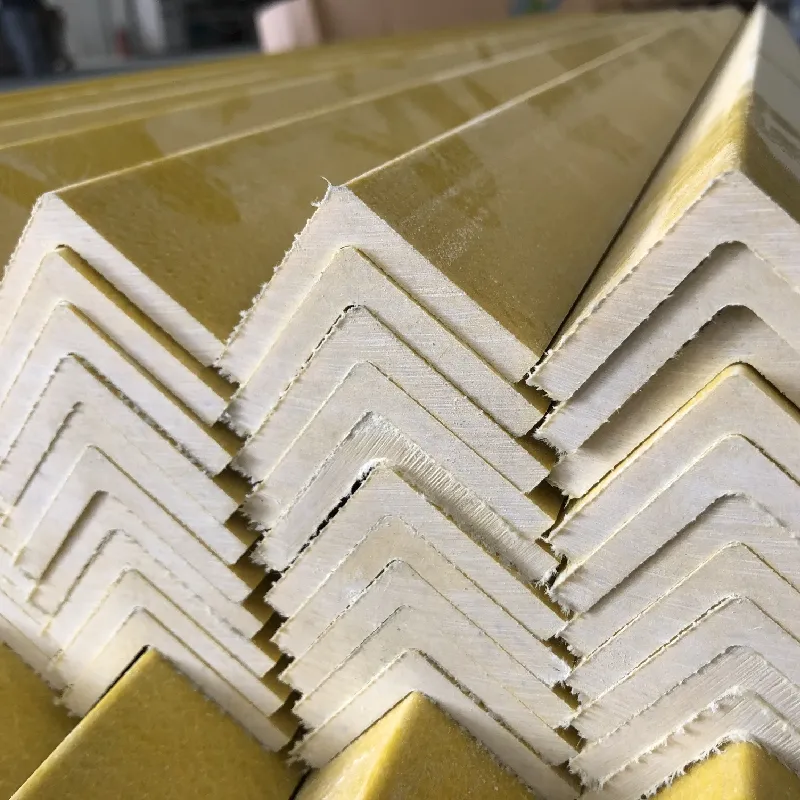

Revolutionizing Structural Design with Advanced Frp Pultrusion Profiles

The evolution of modern construction and industrial manufacturing continues to demand materials that overcome the inherent limitations of traditional options like steel, aluminum, and wood. ZJ Composites addresses these challenges through our sophisticated manufacturing capabilities and technical expertise in advanced composite materials. Our frp profiles represent a significant leap forward in structural component technology, offering performance characteristics that transcend what conventional materials can provide. These engineered products embody our core philosophy of "Better Composites, Better than Metal," delivering exceptional corrosion resistance, structural integrity, and long-term value that position them as the intelligent choice for forward-thinking projects. The frp pultruded profiles we manufacture demonstrate remarkable versatility across applications ranging from corrosive industrial environments to demanding structural applications where weight, maintenance, and durability are primary concerns. Our commitment to revolutionizing composite materials through premium innovation ensures that every component we produce meets the highest standards of quality and performance, providing our wholesale partners with reliable solutions that build confidence among engineers, contractors, and end-users across global markets.

Manufacturing Excellence Behind Frp Pultruded Profiles

The exceptional quality and consistent performance of ZJ Composites' structural components stem from our sophisticated manufacturing methodology and unwavering commitment to quality control throughout the production process. Our pultrusion technology represents a continuous manufacturing technique that pulls reinforced fibers through a resin impregnation system and into a heated die where the composite material undergoes precise curing under controlled conditions. This manufacturing approach ensures that our frp pultruded sections maintain dimensional stability and mechanical properties along their entire length, providing reliable predictability for engineering applications and structural calculations. The company operates according to scientific and standardized management principles implemented through modern enterprise systems, with specialized production teams conducting rigorous inspections at every manufacturing stage using our advanced testing equipment and quality verification protocols. This meticulous attention to manufacturing excellence ensures that every shipment of frp pultruded profiles delivered to our wholesale partners meets the strictest standards for fiber content, resin formulation, dimensional accuracy, and surface quality. The resulting products demonstrate uniform structural properties, consistent surface finish, and reliable performance characteristics that build confidence among engineers, contractors, and end-users who specify our components for their most challenging projects across global markets.

Technical Advantages of Advanced Frp Profiles

The material properties and engineering characteristics of ZJ Composites' structural components deliver compelling advantages over traditional materials across multiple performance dimensions that directly impact project success and long-term operational costs. The most significant benefit lies in the complete corrosion immunity of our frp pultruded profiles, which withstand exposure to chemicals, saltwater, and atmospheric conditions that would rapidly deteriorate metal alternatives, thereby eliminating ongoing maintenance expenses associated with protective coatings and corrosion-related repairs. This corrosion resistance combines with an exceptional strength-to-weight ratio that sees our frp profiles typically weighing approximately one-quarter of comparable steel sections while delivering similar load-bearing capacities, resulting in substantial savings in transportation, handling, and installation labor costs. The non-conductive nature of the composite materials provides inherent electrical insulation properties that enhance safety in applications involving electrical components or utility infrastructure, while the low thermal conductivity improves energy efficiency in building envelopes and temperature-controlled environments. The ultraviolet-resistant formulations and color-through pigmentation ensure long-term aesthetic performance without fading or surface degradation, maintaining appearance without periodic painting or refinishing. These technical advantages collectively contribute to the extended service life and reduced total cost of ownership that make our frp pultruded profiles the intelligent choice for forward-thinking specifiers and project developers across multiple industries.

Diverse Applications for Structural Frp Pultruded Sections

The versatile performance characteristics of ZJ Composites' engineered components make them suitable for an extensive range of applications across multiple industries where environmental challenges, structural requirements, or maintenance constraints render traditional materials impractical or economically unviable. In corrosive industrial environments including chemical processing plants, water treatment facilities, and mining operations, our frp pultruded profiles serve as structural supports, walkway frameworks, handrail systems, and cable tray supports that maintain integrity despite exposure to aggressive substances that would rapidly compromise metal alternatives. The electrical and telecommunications sectors utilize our non-conductive frp profiles for ladder support systems, antenna mounts, and substation structures where electrical isolation represents a critical safety consideration. Marine and waterfront applications benefit tremendously from the saltwater corrosion resistance of our frp pultruded sections when used for dock structures, boat ramps, pier supports, and marine walkways that withstand constant exposure to harsh marine environments without degradation. The construction industry increasingly specifies our products for building reinforcement, window frames, structural elements, and architectural features where the thermal insulation properties, design flexibility, and maintenance-free characteristics provide distinct advantages over conventional materials. This broad applicability demonstrates our company's successful strategy of developing versatile solutions that address genuine market needs through technological innovation and customer-focused product development.

Strategic Partnership with Leading Frp Profiles Manufacturer

Selecting ZJ Composites as your manufacturing partner for structural components represents a strategic decision to align with a company dedicated to quality excellence, technical innovation, and comprehensive customer support throughout the business relationship. Our organizational structure uniquely positions us to serve wholesale partners through two specialized teams working in concert – production specialists implementing rigorous quality control protocols throughout the manufacturing process, and customer service professionals with international experience providing responsive support and technical guidance. This dual-capability approach ensures that our partners receive not only premium frp pultruded profiles but also the comprehensive service necessary for successful project specification and implementation. We maintain an active customer feedback system that continuously gathers insights from our distribution network, enabling ongoing product refinement and service enhancement aligned with evolving market requirements. This commitment to full and decent cooperation reflects our fundamental business philosophy of achieving win-win outcomes through quality products and thoughtful service, establishing the foundation for enduring business relationships built on mutual success and shared objectives. Our vision of cultivating brand loyalty through consistent performance and reliable partnership drives every interaction with our wholesale clients, ensuring they receive the optimal solutions and support necessary to compete effectively in their respective markets.

Frp Pultrusion Profiles FAQ

What are the primary advantages of using frp pultruded profiles over traditional materials?

Frp pultruded profiles offer complete corrosion resistance, high strength-to-weight ratio, electrical insulation, and minimal maintenance requirements compared to traditional materials like steel or aluminum.

How does the cost of frp profiles compare to steel or aluminum sections?

While initial material cost may be higher, frp profiles deliver significantly lower lifetime costs due to eliminated maintenance, easier installation, and longer service life without replacement.

What quality control measures are implemented for frp pultruded sections?

We implement rigorous quality control including raw material verification, process monitoring, dimensional checks, and mechanical testing to ensure all frp pultruded sections meet specifications.

What types of frp pultruded profiles are available from your company?

We manufacture a comprehensive range of standard and custom frp pultruded profiles including I-beams, channels, angles, tubes, and custom sections for specific applications.

What technical support is available for projects using frp profiles?

We provide complete technical support including engineering data, specification guidance, installation recommendations, and custom design services for projects using our frp profiles.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025