loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Revolutionizing Industrial Flooring with Advanced FRP Grating

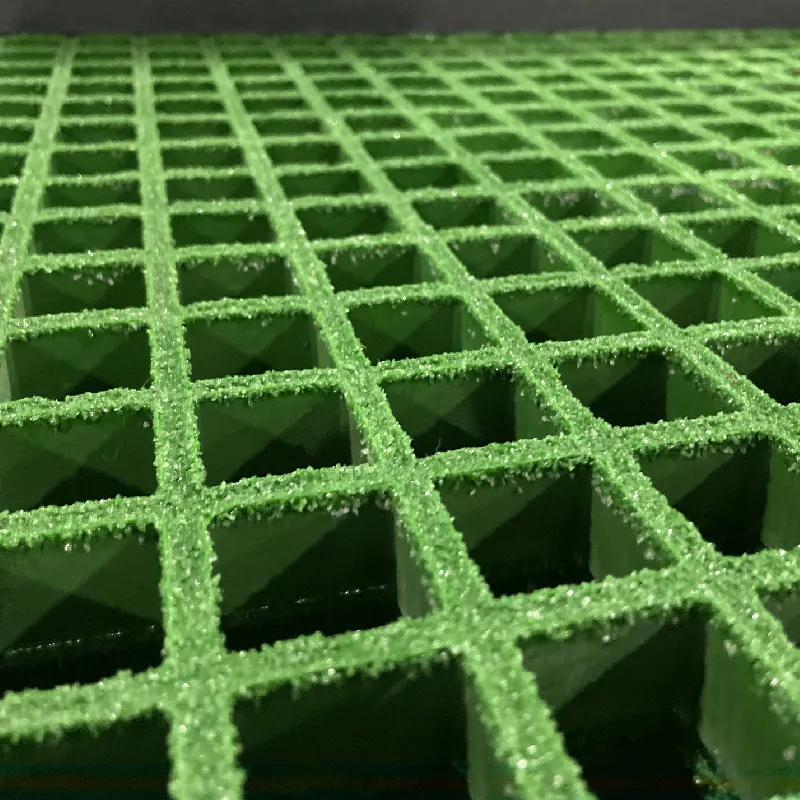

Across global industries, a quiet revolution is reshaping the very floors beneath workers' feet. Traditional materials that have dominated industrial settings for generations are gradually being replaced by solutions offering unprecedented performance characteristics and economic advantages. ZJ Composites has emerged as a pivotal force in this transformation, serving as a dedicated manufacturing partner for wholesalers seeking to provide their clients with grating de frp systems that transcend conventional limitations. These advanced composite solutions deliver a combination of properties that address the most persistent challenges faced by facilities operating in corrosive, electrically sensitive, or structurally demanding environments. The inherent corrosion resistance of our frp protruded grating eliminates the gradual degradation that plagues metallic alternatives, while the exceptional strength-to-weight ratio enables installations that would be impractical with heavier materials. This evolution in industrial flooring technology aligns perfectly with our mission of revolutionizing composite materials through premium innovation, providing wholesalers with products that consistently outperform expectations and establish new benchmarks for safety, durability, and cost-effectiveness across countless applications worldwide.

Engineering Principles Behind Frp Protruded Grating

The exceptional performance characteristics distinguishing ZJ Composites' flooring systems originate from sophisticated manufacturing methodologies refined through years of technical development and quality refinement. Our production of frp protruded grating employs a continuous manufacturing process that precisely orients reinforcing fibers within an optimized resin matrix, creating structural elements with exceptional consistency and predictable mechanical behavior. This manufacturing approach ensures that our frp platform grating maintains uniform structural properties throughout every production run, providing engineers and architects with reliable performance data for structural calculations and safety compliance. The manufacturing environment operates under scientific management principles with integrated quality verification at each production stage, utilizing advanced testing equipment to validate material composition, dimensional accuracy, and load-bearing capabilities before products enter our distribution network. This systematic attention to manufacturing precision ensures that every delivery of grating de frp meets stringent specifications for fiber alignment, resin distribution, and surface characteristics. The resulting products demonstrate consistent structural performance, reliable anti-slip properties, and predictable long-term behavior that establishes confidence among professionals specifying these systems for demanding industrial, commercial, and infrastructure applications where failure is not an option.

Performance Advantages of Frp Platform Grating

The material science underlying ZJ Composites' industrial flooring solutions delivers measurable advantages across multiple performance dimensions that directly influence operational safety, maintenance budgets, and facility longevity. The most transformative characteristic of our frp platform grating lies in its complete immunity to corrosive degradation, maintaining structural integrity when exposed to chemicals, saltwater, and atmospheric conditions that systematically destroy metallic alternatives. This corrosion resistance fundamentally alters the economic equation for industrial flooring by eliminating recurring expenses for protective coatings, corrosion-related repairs, and premature replacement that typically plague traditional materials. Complementing this durability is an exceptional strength-to-weight ratio that sees our frp protruded grating supporting substantial loads while weighing significantly less than steel equivalents, creating opportunities for simplified installation, reduced structural support requirements, and lower transportation costs. The non-conductive nature of the composite materials provides inherent electrical insulation properties that enhance personnel safety in environments with electrical equipment or utility infrastructure, while the integrally molded anti-slip surface delivers reliable traction under conditions that would create hazardous situations with alternative materials. These performance characteristics collectively establish a new paradigm for industrial flooring that prioritizes both safety and economic efficiency through extended service life and minimal maintenance requirements.

Application Spectrum for Frp Grating Sheet Solutions

The versatile performance profile of ZJ Composites' composite flooring systems enables deployment across an extraordinary range of applications where environmental challenges, structural requirements, or maintenance limitations render traditional materials economically or practically problematic. Within industrial processing facilities handling corrosive substances, our frp grating sheet products function as walkways, work platforms, and access structures that maintain structural integrity despite constant exposure to chemicals that would rapidly compromise metal alternatives. The water management sector utilizes our corrosion-resistant grating de frp for treatment plant walkways, filter bed access, and overflow channels where continuous moisture exposure and chemical treatment would destroy conventional materials. Marine and coastal installations benefit from the saltwater immunity of our frp platform grating when deployed as dock surfaces, pier walkways, and offshore access structures that withstand unremitting exposure to marine environments without protective coatings or frequent replacement. The food processing industry increasingly specifies our products for production area flooring, inspection platforms, and drainage covers where the non-absorbent surface, corrosion resistance, and cleanability provide distinct advantages over materials that harbor bacteria or deteriorate under frequent washing. This diverse application range demonstrates our focused strategy of developing engineered solutions that address specific industrial challenges through material science innovation and customer-informed product refinement.

FRP Grating FAQ

What distinguishes frp protruded grating from molded alternatives in performance terms?

Frp protruded grating typically offers higher fiber concentration and directional strength properties, making it particularly suitable for applications requiring maximum stiffness and load-bearing capacity in specific orientations.

How does the installation process for frp platform grating compare to traditional steel grating?

The significantly lighter weight of frp platform grating enables faster installation with smaller crews and less equipment, while the modular design often simplifies cutting and fitting around existing structures.

What design variations are available within your frp grating sheet product range?

Our frp grating sheet products include various mesh patterns, surface treatments, and resin formulations tailored to specific environmental exposures, load requirements, and safety considerations.

What certification standards does your grating de frp comply with for international projects?

Our grating de frp meets numerous international standards for structural performance, slip resistance, and material properties, with documentation available to support project specification and regulatory compliance.

What technical resources are available for projects specifying frp platform grating?

We provide comprehensive technical support including load span tables, chemical resistance charts, installation details, and custom engineering assistance for projects implementing frp platform grating.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025