loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

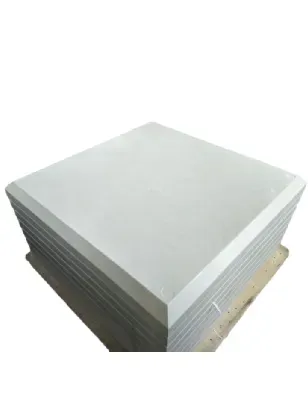

GRP Grating Covers for Enhanced Durability and Safety in Industrial Applications

Understanding GRP Grating Cover A Comprehensive Overview

In the realm of industrial applications and construction, effective flooring systems and access pathways are vital for safety and functionality. One of the solutions that has gained significant attention is the GRP (Glass Reinforced Plastic) grating cover. This advanced material offers numerous advantages over traditional flooring options, making it an increasingly popular choice in various sectors.

What is GRP Grating?

GRP grating is a composite material made from a polymer matrix reinforced with glass fibers. This combination results in a lightweight, strong, and durable product that possesses excellent resistance to corrosive environments and impacts. GRP grating comes in various configurations, including different thicknesses, sizes, and grid patterns, making it versatile for numerous applications.

Benefits of GRP Grating Cover

1. Corrosion Resistance One of the most significant advantages of GRP grating covers is their inherent resistance to corrosion. Unlike metal grating, which can rust when exposed to moisture and harsh chemicals, GRP remains unaffected, making it ideal for areas prone to chemical spills or coastal environments.

2. Lightweight yet Strong GRP follows the principle of high strength-to-weight ratio. This feature simplifies installation and reduces the load on supporting structures, making it an attractive choice for both temporary and permanent applications.

3. Low Maintenance With minimal upkeep requirements, GRP grating covers prove to be a cost-effective solution over their lifetime. They do not need regular painting or treatment, reducing long-term maintenance costs.

4. Fire Resistance Many GRP products are manufactured to meet stringent fire-retardant standards. This attribute enhances safety in industrial workplaces, particularly in sectors such as oil and gas or chemical production, where fire hazards are prominent.

grp grating cover

5. Ease of Installation GRP grating covers can be easily cut and shaped on-site. This adaptability allows for swift installations, crucial in time-sensitive projects, and minimizes disruption in active work environments.

6. Slip-Resistant Surface GRP grating typically features a slip-resistant surface that is essential for workplaces where spills or wet conditions may occur. This characteristic enhances safety for personnel navigating walkways and industrial floors.

Applications of GRP Grating Covers

The usage of GRP grating covers spans across numerous industries, each benefiting from their unique properties. In petrochemical facilities, GRP provides not only structural strength but also resistance to a variety of chemicals. In water treatment plants, it is favored for its customization potential and resistance to elements, while in pedestrian walkways, it ensures safety and comfort for foot traffic.

Additionally, GRP is utilized in recreational environments, such as heavy-duty decking for outdoor facilities, balconies, and pool surrounds. The options for colors and surface textures allow designers to create visually appealing spaces without sacrificing safety and functionality.

Environmental Considerations

In today's eco-conscious world, sustainability plays a critical role in material selection. GRP grating covers can be engineered from recycled or environmentally friendly materials, contributing to sustainable building practices. Moreover, their longevity reduces the frequency of replacement, minimizing waste generated from discarded materials.

Conclusion

In summary, GRP grating covers represent a robust solution for various flooring and access needs across multiple industries. Their combination of strength, lightweight design, corrosion resistance, and low maintenance requirements makes them an ideal choice for both industrial and commercial applications. As industries continue to evolve and prioritize safety and efficiency, the adoption of GRP products is likely to increase, showcasing their relevance in contemporary construction and maintenance practices. Overall, GRP grating covers offer a compelling option for those looking to enhance the durability and safety of their facilities.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025