loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

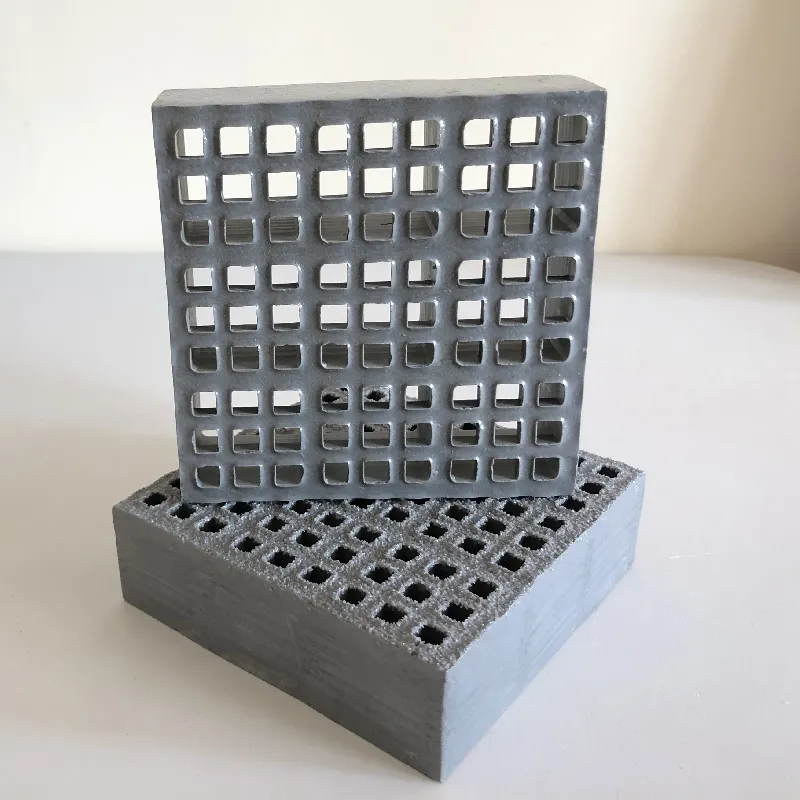

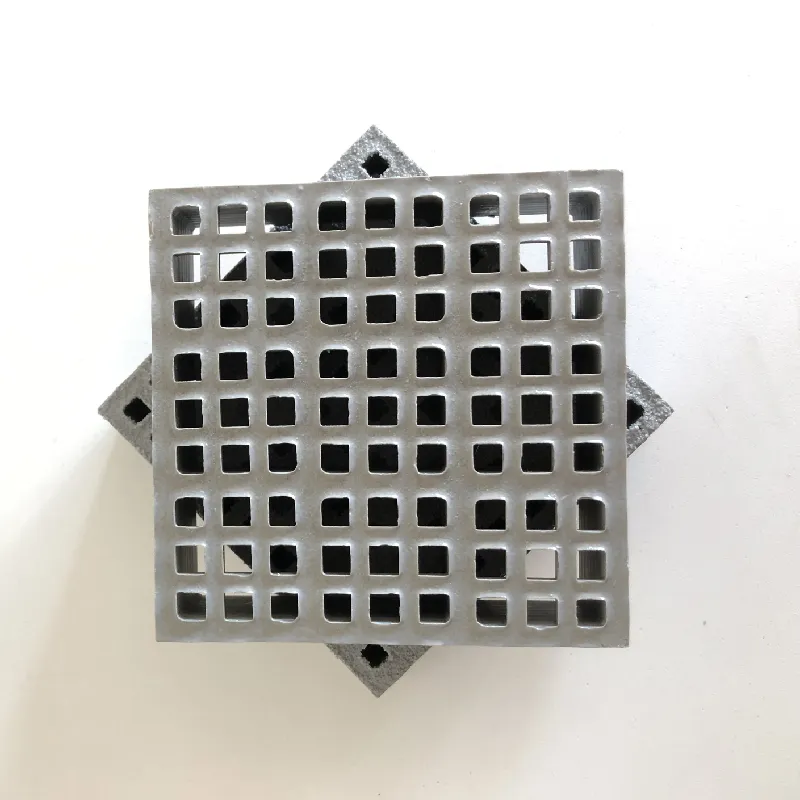

Micro Mesh Grating | Anti-Slip, Corrosion-Resistant FRP

Light Weight and High Strong FRP Micro Mesh Grating: notes from the catwalks

If you spend any time on industrial walkways (I do, more than I’d admit at dinner), you’ll know why micro mesh grating is having a moment. The double-layer, micro‑porous design closes the opening rate, so stray bolts and tools are far less likely to drop through. And because it’s FRP, you get the familiar corrosion resistance without the dead weight or rust drama. Honestly, it’s the kind of quiet upgrade that safety managers and maintenance teams end up loving.

Why the industry is shifting

Three trends keep coming up: tighter safety policies for high-altitude walkways, corrosive environments pushing beyond galvanized steel, and a push to cut lifecycle costs. In fact, many customers say the quieter benefit is vibration damping—wheeled carts roll smoother on micro mesh grating, which sounds trivial until you’ve watched a cart rattling along an elevated pipe bridge.

How it’s made (quick process flow)

- Materials: E-glass rovings, isophthalic or vinyl ester resin, UV stabilizers, fire retardants; anti-slip grit top (quartz/silica).

- Method: Molded, double-layer, cross-grid layup; controlled resin wet-out; thermal cure; post-cure to stabilize mechanicals.

- Finish: Trim, seal cut edges, grit application (medium or coarse), optional conductive additive.

- Testing: Flexural per ASTM D790; burning rate per ASTM D635; surface burning per ASTM E84; slip per ANSI A326.3 (or EN 13036/BS 7976 pendulum, if requested).

- Service life: ≈20–30 years in typical chemical/water treatment atmospheres; real-world use may vary with UV/chemicals.

- Industries: Chemical, offshore, wastewater, food & beverage, public infrastructure, power, rooftop MRO.

Typical specifications (representative)

| Panel size | ≈1220×3660 mm (other sizes on request) |

| Thickness | 25–38 mm, double-layer micro-porous |

| Mesh aperture | Around 8–13 mm micro mesh |

| Open area | ≈30–45% (reduced to prevent object fall-through) |

| Weight | ≈10–16 kg/m² (depends on thickness/resin) |

| Resin systems | ISO polyester / vinyl ester (chemical duty) |

| Surface | Grit top or meniscus; slip tested to ANSI A326.3 |

| Fire | ASTM E84 Class 1; ASTM D635 self-extinguishing |

| Color | Safety yellow/green/grey; custom on MOQ |

Internal lab data shows wet DCOF ≥0.60 (ANSI A326.3) with grit finish; to be honest, site conditions can nudge that number.

Where it shines

High-altitude catwalks, mezzanines with tool-drop risk, rooftops near HVAC (wheel traffic), and chemical plants where steel grates fatigue. Advantages? Corrosion resistance, less vibration, simpler lifting/installation, and fewer “oops” moments with small parts. One maintenance lead told me, “we switched to micro mesh grating and stopped fishing sockets from the river.”

Vendor snapshot (quick comparison)

| Vendor | Material | Weight (≈) | Corrosion | Lead time (around) |

|---|---|---|---|---|

| ZJ Composites (Hebei, China) | FRP micro mesh | 10–16 kg/m² | Excellent | 2–4 weeks (customs may vary) |

| Aluminum grating reseller | Al 6061/6063 | ≈18–22 kg/m² | Good, not chemical-strong | Stock-to 3 weeks |

| Steel fabricator | HDG steel bar | ≈35–45 kg/m² | Fair (needs maintenance) | 2–6 weeks |

Two quick field stories

Chemical catwalk retrofit: A northern plant swapped corroded steel for micro mesh grating. Install time dropped ≈30% thanks to lighter panels; after 18 months, no rust touch-ups and fewer reported “dropped item” incidents.

Rooftop service path: Facility team added double-layer micro mesh near chillers; cart vibration fell noticeably, and slip resistance in misty mornings stayed consistent (PTV >45, internal pendulum test). Feedback was basically, “set it and forget it.”

Compliance, data, and customization

Certifications: ISO 9001 quality system; fire tested to ASTM E84 Class 1; self-extinguishing per ASTM D635. Flexural properties validated per ASTM D790 (typical molded FRP: modulus ≈8–12 GPa; strength ≈150–250 MPa—resin and layout dependent). Slip measured to ANSI A326.3; site audits on request.

Customization: panel sizes, resin grade (ISO/VE), surface grit, color coding, conductive options, edge banding, and pre-fab stair treads. Origin: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China.

References

- ASTM D790 – Standard Test Methods for Flexural Properties of Plastics and Composites.

- ASTM E84 – Surface Burning Characteristics of Building Materials.

- ASTM D635 – Standard Test Method for Rate of Burning and/or Extent and Time of Burning of Plastics.

- ANSI A326.3 – Dynamic Coefficient of Friction Test Method for Hard Surface Flooring.

- ISO 9001:2015 – Quality Management Systems Requirements.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025