loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

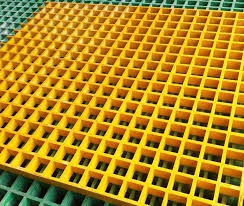

Innovative Solutions in FRP Molded Grating for Enhanced Durability and Performance

Understanding FRP Moulded Grating A Comprehensive Overview

FRP (Fiberglass Reinforced Plastic) moulded grating has emerged as a revolutionary material in the construction and manufacturing industries. Known for its exceptional strength, durability, and corrosion resistance, FRP grating is predominantly utilized in environments that demand lightweight yet robust flooring solutions. This article delves into the various aspects of FRP moulded grating, including its composition, benefits, applications, and considerations for use.

Composition and Manufacturing

FRP moulded grating is manufactured using a composite material that combines fiberglass with a resin matrix, typically polyester or vinyl ester. The manufacturing process involves the use of a moulding technique that creates a grid-like structure, which provides both strength and lightweight properties. The fiberglass reinforcements are strategically placed to enhance tensile strength, while the resin serves to protect against environmental factors such as moisture and chemicals.

The production of FRP grating can be tailored to meet specific performance requirements. By adjusting the type and amount of resin and fiberglass used, manufacturers can create grating with varying degrees of thickness, load-bearing capacities, and resistance to impact or harsh chemicals. This versatility makes FRP moulded grating suitable for a wide range of applications across multiple industries.

Key Benefits of FRP Moulded Grating

1. Corrosion Resistance One of the primary advantages of FRP grating is its excellent resistance to corrosive substances, including chemicals and saltwater. This makes it an ideal choice for industries such as wastewater treatment, chemical processing, and marine applications.

2. Lightweight FRP grating is significantly lighter than traditional materials like steel or wood, reducing the overall weight of structures. This not only facilitates easier handling and installation but also minimizes the load on supporting structures.

3. Safety Features The surface of FRP grating can be designed with anti-slip properties, ensuring that it provides secure footing in wet or oily conditions. Additionally, the non-conductive nature of FRP minimizes the risk of electrical hazards.

4. Durability FRP moulded grating exhibits exceptional durability and can withstand heavy loads and impacts. Its resistance to UV radiation ensures that it does not degrade or lose its physical properties even when exposed to sunlight over extended periods.

5. Low Maintenance Unlike traditional materials that may require regular painting, staining, or sealing, FRP grating requires minimal maintenance, leading to reduced lifecycle costs.

Applications Across Industries

frp moulded grating

FRP moulded grating has found its place in various applications. Some of the most common include

- Industrial Flooring Used in factories, warehouses, and assembly plants, FRP grating provides a safe and durable flooring solution that can accommodate heavy machinery and foot traffic.

- Walkways and Platforms Its lightweight nature and strength make it suitable for walkways, observation platforms, and maintenance access areas in industrial settings.

- Wastewater Treatment Plants The corrosion-resistant properties of FRP make it a popular choice for grating in wastewater facilities, where exposure to harsh chemicals and constant moisture is common.

- Marine Applications FRP grating is extensively used in shipbuilding, docks, and marinas due to its resistance to saltwater and marine organisms.

- Chemical Processing Plants The ability of FRP to withstand corrosive chemicals makes it an invaluable asset in chemical manufacturing environments.

Considerations for Use

While FRP moulded grating offers numerous advantages, it is essential to consider specific factors before selection and installation

- Load Requirements Different types of FRP grating are designed to handle varying load capacities. Understanding the specific weight and operational loads is crucial for choosing the right grating.

- Environmental Conditions The anticipated exposure to chemicals, temperatures, and other environmental factors can influence the type of resin and fiberglass used.

- Regulatory Compliance Depending on the application, certain industries may have regulations that specify safety and performance standards for materials used in construction.

In conclusion, FRP moulded grating is a versatile, durable, and economically viable solution that addresses the flooring needs of various industries. Its unique properties make it a preferred choice in environments where traditional materials may fall short. As technology advances, the applications and benefits of FRP grating will likely continue to expand, solidifying its role in modern construction and infrastructure development.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025