loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

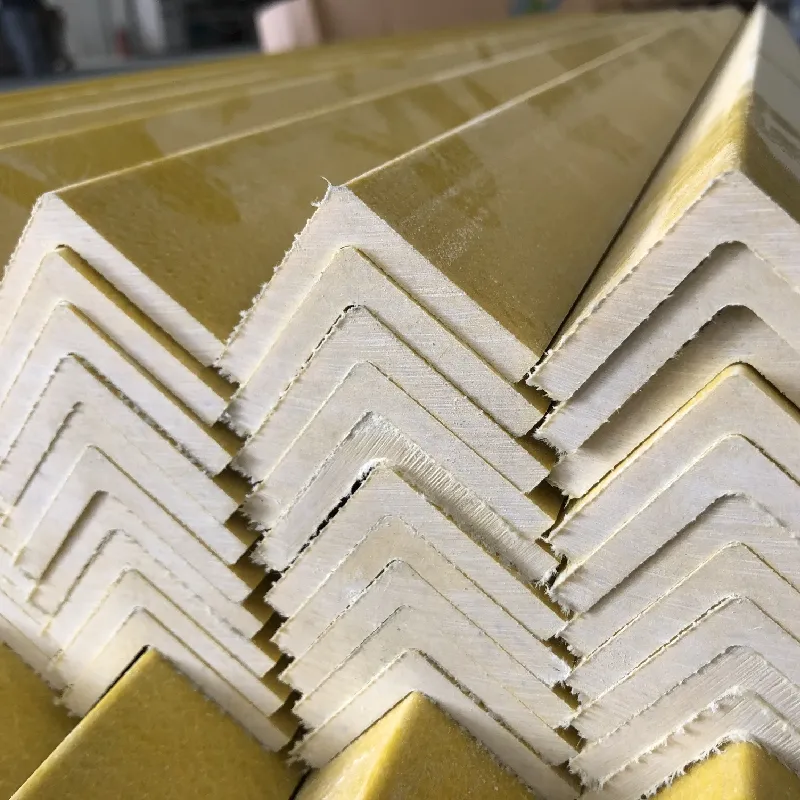

Pultruded FRP Profiles: Lightweight, Corrosion-Resistant

What Builders Are Really Saying About [Frp Profiles]

If you spend enough time on job sites (I do), you’ll hear the same refrain: corrosion, weight, and downtime are killing budgets. That’s exactly why the High Strength FRP Pultruded Profile Fiberglass I Beam for Construction from ZJ Composites keeps popping up in specs and RFPs. In fact, many customers say the switch paid for itself just in avoided repainting and crane hours. It’s not hype—just a quieter shift away from steel and aluminum toward composite beams that don’t rust, don’t spark, and don’t weigh a ton.

Industry trends and where these beams actually go

We’re seeing steady adoption in water/wastewater, chemical plants, coastal infrastructure, data centers (non-conductive catwalks), transit platforms, and rooftop HVAC supports. Surprisingly robust uptake in food processing too—washdown plus chlorine is nasty on metals. To be honest, designers like the weight savings: lighter I-beams mean smaller foundations and cheaper installs.

- Corrosive zones: clarifiers, scrubbers, pickling lines

- Marinas and coastal walkways—salt spray is no problem

- Electrical substations—non-conductive safety rails and supports

- Retrofit on aging steel platforms where crane access is tough

How they’re made (and why it matters)

Pultrusion is continuous. E-glass rovings and mats are guided through a resin bath (polyester or vinyl ester for higher chemical resistance), then aligned in a heated die to cure into net-shape profiles. ZJ Composites runs tight resin-to-glass ratios, which, in real-world use, means better stiffness without excess brittleness. QC typically references ASTM D638/D790 for strength and flexural checks, ASTM E84 for flame spread, and UV/weathering under ASTM G154. Service life? Around 25–50 years depending on UV exposure and chemicals; I’ve seen 15-year-old pieces in coastal air that still look fresh.

Product snapshot and indicative data

| Attribute | Typical Value (≈) / Notes |

|---|---|

| Profile | Pultruded I-beam, custom heights 100–300 mm |

| Reinforcement / Resin | E-glass roving + mat / Polyester or Vinyl Ester |

| Density | ≈1.8–2.0 g/cm³ (about 1/4 the weight of steel) |

| Tensile Strength (ASTM D638) | ≈240–450 MPa, resin system dependent |

| Flexural Strength (ASTM D790) | ≈300–500 MPa; Modulus ≈20–28 GPa |

| Fire / Smoke | ASTM E84 Class 1 options; real-world use may vary |

| UV / Weathering | UV veil & gelcoat; ASTM G154 tested |

| Length / Tolerance | Up to 12 m standard; custom on request; ±1–2 mm typical |

Certification-wise, ZJ Composites operates with ISO 9001 QA, and provides test reports upon request. Plant origin: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China.

Why builders pick Frp Profiles over steel or aluminum

- Corrosion immunity lowers life-cycle cost—no repainting cycles

- Non-conductive and non-magnetic—safer near live equipment

- Lightweight—faster installs, smaller cranes, fewer crew hours

- On-site fabricable—diamond blade, carbide bits, standard PPE

Vendor comparison (quick take)

| Vendor | Certs | Customization | Lead Time | QC / Testing | Indicative Cost |

|---|---|---|---|---|---|

| ZJ Composites | ISO 9001; ASTM/EN reports | High—custom dies, colors, resin | ≈2–5 weeks | Batch-by-batch per ASTM D638/D790 | Mid, strong value |

| EU Maker A | ISO 9001/14001 | Medium—standard die library | ≈4–8 weeks | EN 13706 focus | High |

| Generic Importer | Varies | Low—limited resin choices | ≈1–3 weeks | Basic COA; limited third-party | Low, but QC risk |

Case notes and feedback

A coastal wastewater platform swapped steel grating and beams for Frp Profiles. Result: install time down 30%, no rust bleed after 18 months, zero repaint budget so far. Another client—an OEM conveyor line—liked the non-conductive, spark-free supports near sensors; they reported fewer nuisance faults. It seems that when maintenance teams are looped in early, composites win the life-cycle debate.

Customization pointers

Pick vinyl ester for aggressive chemicals, add UV veil for rooftop installs, specify color coding (OSHA safety yellow is common), and ask for third-party test data. For structural calcs, reference EN 13706 or supplier design guides, and—this is key—use the directional properties of Frp Profiles (fiber alignment) in your safety factors.

Citations

- ASTM D638: Standard Test Method for Tensile Properties of Plastics

- ASTM D790: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics

- ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials

- ASTM G154: Standard Practice for Operating Fluorescent UV Lamp Apparatus for Exposure of Nonmetallic Materials

- EN 13706: Pultruded profiles—Requirements and test methods

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025