loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Fire Resistance of Grating FRP

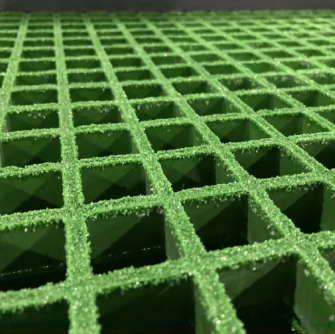

Fire safety is a non-negotiable requirement in industrial, commercial, and residential spaces—and grating FRP (Fiberglass Reinforced Plastic) has emerged as a reliable, fire-resistant solution that balances durability, strength, and safety. Unlike traditional metal or wood gratings that warp, melt, or contribute to fire spread, FRP grating and FRP grating panels are engineered with fire-retardant properties, making them ideal for high-risk areas like factories, chemical plants, or commercial kitchens. Zhaojia Composites Co., Ltd (ZJ Composites), a leader in composite materials with a focus on product quality and innovation, specializes in crafting fire-resistant FRP grating solutions. Equipped with perfect testing equipment and strong technical support, ZJ Composites exports their grating FRP products worldwide, earning trust for their compliance with global fire safety standards. This article explores the fire resistance of grating FRP, highlighting key properties, testing certifications, and why ZJ Composites’ FRP grating panels stand out for wholesalers seeking safe, long-lasting grating solutions.

Key Fire-Resistant Properties of FRP Grating

- Low Flame Spread for FRP Grating Panels: FRP grating panels from ZJ Composites are formulated with fire-retardant resins that limit flame spread—critical for containing fires and giving occupants time to evacuate. When exposed to fire, the resin creates a charred layer that acts as a barrier, preventing the underlying fiberglass from igniting quickly. This property ensures FRP grating meets global standards like ASTM E84 (U.S.) or EN 13501-1 (EU), where it typically achieves a Class B or Class C flame spread rating. Wholesalers can note that this low flame spread makes grating FRP suitable for areas with strict fire codes, such as shopping malls or industrial facilities.

- Smoke and Toxic Gas Reduction for Grating FRP: Unlike metal gratings that release toxic fumes when heated (if coated with certain paints) or wood gratings that produce thick smoke, grating FRP minimizes smoke and toxic gas emissions during a fire. ZJ Composites’ FRP grating uses halogen-free resins, which reduce the release of harmful gases like chlorine or bromine—protecting both people and equipment from smoke inhalation or corrosion. For example, in a chemical plant fire, FRP grating panels would not contribute to toxic smoke, making cleanup safer and reducing long-term damage. This property is a major selling point for wholesalers serving clients in health-sensitive or environmentally regulated industries.

Fire Safety Certifications for FRP Grating

- Global Fire Standards Compliance for Grating FRP: Grating FRP from ZJ Composites undergoes rigorous testing to meet international fire safety standards, ensuring wholesalers can cater to global clients with confidence. Key certifications include:

- ASTM E84 (Standard Test Method for Surface Burning Characteristics of Building Materials): ZJ Composites’ FRP grating achieves a flame spread index (FSI) of ≤25 and smoke developed index (SDI) of ≤450, qualifying it for Class A or B ratings (depending on application).

- EN 13501-1 (European Standard for Fire Classification of Construction Products): FRP grating panels earn a Euroclass B-s1, d0 rating—meaning low flame spread, minimal smoke production, and no flaming droplets.

- GB 8624 (Chinese Standard for Combustion Performance of Building Materials): Complies with Class B1 (difficult to ignite) requirements, suitable for domestic and Asian markets.

- These certifications eliminate compliance barriers for wholesalers, ensuring FRP grating can be used in diverse regions without additional testing.

- On-Site Fire Performance Testing for FRP Grating Panels: ZJ Composites goes beyond third-party certifications by conducting in-house fire performance tests on FRP grating panels—simulating real-world scenarios like direct flame exposure or heat soak. The company’s testing equipment measures parameters like ignition time, flame duration, and residual strength after fire exposure, ensuring FRP grating maintains structural integrity long enough to support emergency response. For example, a grating FRP sample might retain 60% of its strength after 30 minutes of exposure to 800°C heat—proving its reliability in high-temperature emergencies. Wholesalers can share these test results with clients to build trust in the product’s fire resistance.

FRP Grating for Fire-Prone Application Scenarios

|

Application Scenario |

Key Fire Risk |

Ideal FRP Grating Feature |

ZJ Composites Advantage |

|

Industrial Factories |

Chemical spills + open flames. |

Fire-retardant resin + chemical-resistant surface. |

Halogen-free resin + corrosion-resistant fiberglass. |

|

Commercial Kitchens |

Grease fires + high heat. |

Non-porous FRP grating panels + low flame spread. |

Smooth surface (easy to clean grease) + ASTM E84 Class B. |

|

Power Plants |

Electrical sparks + high temperatures. |

Flame-retardant grating FRP + electrical insulation. |

EN 13501-1 Euroclass B-s1, d0 + non-conductive core. |

|

Parking Garages |

Vehicle fires + smoke accumulation. |

Low smoke emission FRP grating + load-bearing strength. |

GB 8624 Class B1 + high weight capacity (up to 500kg/m²). |

Long-Term Fire Resistance Maintenance for FRP Grating

- UV and Chemical Resistance to Preserve Fire Properties: FRP grating’s fire resistance can degrade over time if exposed to harsh elements— but ZJ Composites’ FRP grating panels include UV stabilizers and chemical-resistant coatings that preserve fire-retardant properties. For example, in outdoor applications (like parking garage walkways), UV stabilizers prevent resin breakdown, ensuring the grating retains its flame-retardant qualities for 15–20 years. In chemical plants, the chemical-resistant surface prevents corrosive substances from seeping into the resin and compromising fire performance. Wholesalers can emphasize this low-maintenance benefit: clients don’t need to reapply fire-retardant treatments, reducing long-term costs.

- Inspection and Cleaning Guidelines for Grating FRP: To maintain grating FRP’s fire resistance, ZJ Composites provides simple inspection and cleaning guidelines for clients. Regular checks (every 6–12 months) should look for cracks in the resin (which could reduce fire protection) or buildup of flammable materials (like grease or dust). Cleaning with mild soap and water (avoid harsh chemicals that damage resin) removes flammable debris, ensuring the grating is ready to perform in case of fire. These guidelines are easy for clients to follow, making FRP grating a practical choice for busy facilities— a key advantage for wholesalers.

FRP Grating FAQS

Will FRP Grating Melt in High Temperatures Like Metal Gratings?

No—FRP grating from ZJ Composites does not melt like metal gratings (which typically melt at 1,200–1,500°C). Instead, FRP grating panels soften slightly at high temperatures (around 200–250°C) and form a charred barrier that protects the underlying structure. This char layer maintains the grating’s shape and load-bearing capacity for longer than metal, which can warp or collapse quickly in fires. Wholesalers can assure clients that grating FRP offers superior structural stability during heat exposure.

Is FRP Grating More Expensive Than Fire-Resistant Metal Gratings?

While FRP grating may have a slightly higher upfront cost than basic metal gratings, it is cost-competitive with fire-resistant metal gratings (which require expensive coatings or alloys). Additionally, FRP grating panels have lower maintenance costs (no repainting or rust treatment) and a longer lifespan (15–20 years vs. 10–12 years for coated metal), making them more cost-effective over time. For wholesalers, this total cost of ownership is a key selling point for budget-conscious clients.

Can FRP Grating Be Used in Areas with Open Flames (e.g., Welding Zones)?

Yes—ZJ Composites’ grating FRP is suitable for areas with occasional open flames (like welding zones), thanks to its fire-retardant resin. However, it’s important to note that direct, prolonged exposure to welding sparks may cause minor surface charring (not ignition). To minimize this, ZJ Composites recommends using a temporary heat shield during intense welding activities— a simple precaution that preserves the grating’s long-term fire resistance. Wholesalers can advise clients on this best practice to extend the grating’s life.

Does the Fire Resistance of FRP Grating Decrease Over Time?

No—if maintained properly, grating FRP’s fire resistance remains stable for its entire lifespan. ZJ Composites’ FRP grating uses high-quality, UV-stabilized resins that do not break down easily, and the fiberglass reinforcement retains its structural integrity. Regular cleaning (to remove flammable debris) and inspections (to check for resin cracks) ensure the grating’s fire properties never degrade. Wholesalers can confirm this with clients: FRP grating panels are a long-term fire safety investment.

Where Can Wholesalers Source Fire-Resistant FRP Grating?

Zhaojia Composites Co., Ltd (ZJ Composites) manufactures fire-resistant FRP grating, FRP grating panels, and grating FRP products—all with global fire safety certifications, durable construction, and export-ready quality. With perfect testing equipment and a focus on customer needs, ZJ Composites offers bulk ordering options and customized solutions (e.g., specific panel sizes or resin formulations).

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025