loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Covered Grating: Corrosion-Resistant, Anti-Slip FRP Panels

A Field Note on Covered FRP Flooring: When “Covered Grating” Actually Solves Real Problems

I’ve been on enough plant floors to know when a flooring choice turns into a maintenance sinkhole. The first time I walked across covered grating in a chemical loading bay, I remember thinking: finally—solid, quiet footing without the usual corrosion scars. Since then, I’ve kept tabs on how these panels are built and tested, and how they hold up in the wild.

What It Is and Why It’s Gaining Ground

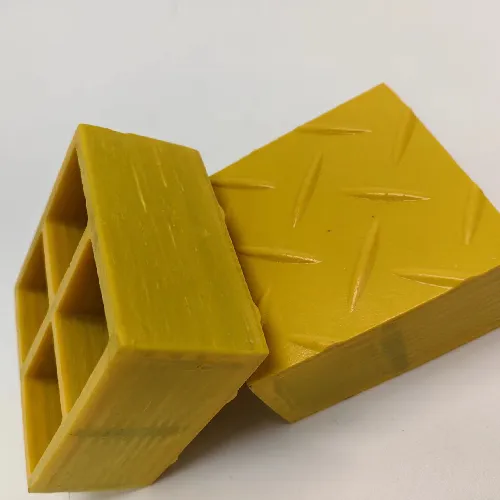

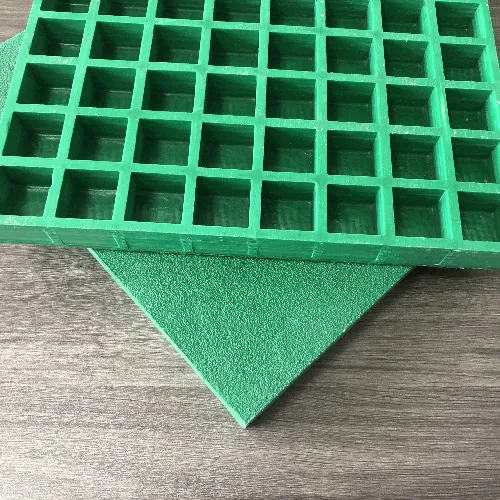

The product in question—Corrosion Resistant and Slip Resistant FRP GRP Fiberglass covered grating—is a molded fiberglass grating topped with a solid plate. That top plate (often grit-coated) does three things plants care about: creates a level surface for foot or cart traffic, blocks drips and debris from contaminating areas below, and, surprisingly often, prevents stiletto-heel catch points. Many customers say it feels ≈30% stiffer than open-mesh grating of the same depth, and that matches what I’ve seen.

Where It’s Used

- Chemical processing, wastewater basins, pulp & paper mezzanines

- Food plants needing top-surface hygiene control

- Marine and offshore walkways where spray + salt = corrosion

- Power plants, battery rooms, plating lines—anywhere steel corrodes fast

Materials, Process, and Testing (Short Version)

Panels are molded FRP (fiberglass-reinforced plastic) with resin choices—typically isophthalic, vinyl ester, or phenolic. The cover plate is co-molded or adhesively bonded, then grit-coated for slip resistance. Plants that take this seriously run gel time checks, barcol hardness, cure profiles, and dimensional inspections. Independent labs often verify flame spread (ASTM E84), mechanicals (ASTM D790/D695), and slip (ANSI A326.3 wet DCOF—real-world use may vary). Service life? Around 20–30 years if you match resin to chemistry and keep UV topcoats in spec.

Product Snapshot

| Item | Typical Value (≈) | Standard | Notes |

|---|---|---|---|

| Panel sizes | 1220×3660 mm, 1000×3000 mm | Factory | Custom cuts available |

| Depth | 25–50 mm | — | Cover plate ≈3–5 mm |

| Flexural strength | ≥ 200 MPa | ASTM D790 | Resin + glass content dependent |

| Compressive strength | ≥ 100 MPa | ASTM D695 | Typical molded FRP |

| Flame spread index | ≤ 25 | ASTM E84 | With fire-retardant resin |

| Wet DCOF | ≥ 0.50 | ANSI A326.3 | Grit top; site conditions vary |

| Certifications | ISO 9001:2015 | QMS | Factory-level |

Customization and Delivery

Colors (gray/green/yellow), resin system by media exposure, grit grades, cutouts for pipe penetrations, and edge banding are all routine. Origin: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China. Lead times are usually steady; to be honest, resin selection can add a week if you’re going niche (phenolic).

How It Compares

| Factor | ZJ Composites covered grating | Galvanized steel plate | Generic FRP (open mesh) |

|---|---|---|---|

| Corrosion resistance | High (resin-matched) | Moderate; coating-dependent | High |

| Slip resistance (wet) | Grit top, strong | Needs serration/paint | Good, but open mesh |

| Weight | Light vs steel | Heavier | Light |

| Solid surface | Yes (controls drips/odors) | Yes | No |

| Maintenance | Low | Rust & repaint cycles | Low |

Two Quick Case Notes

Food plant mezzanine: swapped steel tread plate for covered grating to stop flour fall-through; the housekeeping crew told me, “less sweep time, fewer slip scares.”

Municipal WWTP clarifier deck: vinyl ester covered grating resisted H2S and chlorine splash; maintenance logged zero rust remediation after 18 months—early, but promising.

What to Check Before You Buy

- Chemical resistance chart vs your exact media and temperature. - Required live load and deflection limits (serviceability often governs). - Slip testing under your cleaning regime—detergents can change DCOF. - Fire performance and local code acceptance (ASTM E84, or EN classification where applicable). - Warranty and cutout policy; oddly, edges matter more than people think.

References:

- OSHA 29 CFR 1910 Subpart D – Walking-Working Surfaces. https://www.osha.gov/laws-regs/regulations/standardnumber/1910

- ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials. https://www.astm.org/e0084-23.html

- ANSI A326.3 – Dynamic Coefficient of Friction for Hard Surface Flooring. https://www.tcna.tile.org

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025