loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

grp grating specification

Understanding GRP Grating Specifications

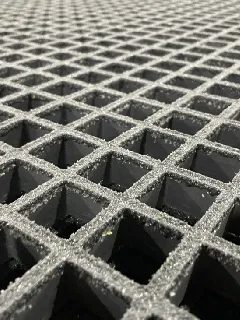

Glass Reinforced Plastic (GRP) grating, commonly known as fiberglass grating, has gained significant traction across various industries due to its outstanding properties. It is a composite material made of a polymer matrix reinforced with glass fibers, which provides exceptional strength and resistance to corrosion. Understanding the specifications of GRP grating is essential for selecting the right product for your application.

Composition and Manufacturing

GRP grating is manufactured using a combination of fiberglass and resin, typically polyester or vinyl ester. The manufacturing process involves layering fiberglass fabric with resin, which is then cured to form a rigid structure. This process can be tailored to produce various grating profiles, including molded and pultruded types. Molded GRP grating is produced by heating and compressing resin and fiberglass in a mold, while pultruded grating is created by continuously drawing the composite material through a heated die.

Key Specifications

1. Load Capacity One of the most critical specifications for GRP grating is its load-bearing capacity. This is typically measured in terms of deflection and ultimate load. Specifications vary based on the grating thickness, spacing between support beams, and the overall configuration. It is essential to consult the manufacturer's load tables to ensure the chosen grating meets the necessary requirements for your application.

2. Span The span refers to the distance between the supports where the grating will be installed. GRP grating can be designed for various spans depending on the load requirements. Proper span measurement is crucial, as exceeding recommended spans can lead to excessive deflection or even failure of the grating.

3. Thickness The thickness of GRP grating typically ranges from 25 mm to 50 mm, and this dimension significantly impacts its strength and load capacity. Thicker grating can support heavier loads and provide better durability, while thinner profiles may be suitable for lighter applications.

grp grating specification

4. Chemical Resistance One of the standout features of GRP grating is its resistance to a wide range of chemicals, making it ideal for industries such as chemical processing, wastewater treatment, and pharmaceuticals. The specific resin formulation can influence the level of chemical resistance, so it’s crucial to confirm compatibility with the intended environment before making a selection.

5. Slip Resistance Safety is paramount in industrial settings, and the slip resistance of GRP grating is an important specification. Manufacturers often provide different surface textures to enhance grip. Testing standards, such as ASTM C1028, are usually referenced to ensure the grating meets safety requirements.

6. Fire Resistance Many industries require materials that comply with fire safety standards. GRP grating can be produced with flame-retardant properties, which is essential in applications where fire risk is a concern. Fire ratings can vary, so understanding the specific requirements of your project is essential.

7. UV Resistance The long-term performance of GRP grating can be affected by ultraviolet (UV) exposure. Manufacturers often include UV inhibitors in their products to enhance durability and reduce surface degradation over time.

Applications

GRP grating is widely used in various applications, from industrial walkways and platforms to marine environments and food processing facilities. Its lightweight construction facilitates easier installation and reduces the overall structural load, making it a preferred choice in many scenarios.

Conclusion

In conclusion, understanding GRP grating specifications is essential for selecting the right material for your project. Factors such as load capacity, span, thickness, chemical and slip resistance, fire safety, and UV stability play crucial roles in determining the suitability of GRP grating for your specific application. By carefully evaluating these specifications, you can ensure the longevity and safety of the installation, ultimately leading to increased efficiency and performance in your operational environment.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025