loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

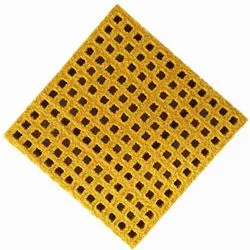

welded bar grating

Understanding Welded Bar Grating A Comprehensive Overview

Welded bar grating is a versatile and widely used material in various industrial and construction applications. It consists of a series of load-bearing bars welded to a series of crossbars, forming a grid-like structure. This design provides significant strength and durability, making welded bar grating an ideal choice for platforms, walkways, and even architectural features in buildings.

Composition and Manufacturing

Welded bar grating is typically made from steel, although it can also be manufactured from aluminum and fiberglass. The manufacturing process involves placing the load bars closely together and then welding them at regular intervals to the crossbars. This method creates a stable, robust structure that can support heavy loads while remaining lightweight and easy to install.

There are various standard sizes and patterns for welded bar grating, but customization is also available to meet specific project requirements. The load-bearing bars can be configured in a variety of thicknesses, widths, and spacing, providing engineers and designers with the flexibility to choose the appropriate type for their needs.

Advantages of Welded Bar Grating

One of the primary advantages of welded bar grating is its strength-to-weight ratio. This means that even though it is lightweight, it can support substantial weight loads, making it suitable for applications that require durability without the burden of excessive weight. This characteristic is essential for safety in industrial environments, where employees may be working above ground on platforms or catwalks.

welded bar grating

In addition to structural strength, welded bar grating is also highly resistant to corrosion, especially when hot-dip galvanized or coated with protective finishes. This resistance makes it suitable for outdoor use and in environments with high humidity or exposure to chemicals. The open design of bar grating allows rainwater and debris to fall through, reducing the risk of slipping and enhancing safety.

Applications

Welded bar grating finds applications across a variety of industries, including construction, manufacturing, and chemical processing. In industrial settings, it is frequently used as flooring for mezzanines and platforms, walkways for machinery and equipment access, and stair treads. Its durability and low maintenance requirements make it a cost-effective choice over time.

In the construction sector, welded bar grating is often utilized in architectural applications as aesthetic features, such as railings, facades, and decorative screens. The various finishes available allow for creativity without compromising on safety and functionality.

Conclusion

In summary, welded bar grating is a practical and reliable solution for a wide range of applications. Its impressive strength, lightweight nature, corrosion resistance, and aesthetic versatility make it a favored choice for engineers and architects alike. When considering flooring or structural solutions, welded bar grating offers the perfect balance of functionality and design, ensuring safety while enhancing the aesthetic appeal of buildings and industrial facilities. Whether for heavy-duty industrial use or lightweight architectural applications, welded bar grating proves to be an invaluable asset in various domains.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025