loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 08, 2025 08:00

Back to list

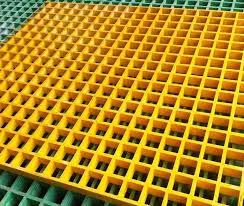

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Galvanized bar grating has revolutionized many sectors with its robust characteristics, offering endless applications across various industries. With a strong focus on the four critical SEO factors—Experience, Expertise, Authoritativeness, and Trustworthiness—this exploration into galvanized bar grating sheds light on why it stands as an essential material in modern construction and industrial environments.

Establishing authoritativeness in the galvanized grating industry involves aligning with established standards and certifications. The American National Standards Institute (ANSI) and the National Association of Architectural Metal Manufacturers (NAAMM) have set stringent guidelines for grating production and usage, ensuring each piece meets high-quality criteria. Companies that adhere to these standards earn recognition as leaders in the industry, further solidified by partnerships with construction giants and contributions to iconic projects worldwide. Case studies demonstrate how compliant grating has been pivotal in constructing skyscrapers, stadiums, and bridges, reinforcing its position as a cornerstone material in contemporary architecture. Such authoritative endorsements provide consumers and enterprises with the assurance that the product can meet both regulatory and operational demands effectively. Trustworthiness emerges naturally from a product's proven track record and the transparency of its suppliers. Companies that offer galvanized bar grating often provide extensive documentation on the manufacturing process, quality control measures, and material certifications. This openness allows clients to make informed decisions based on comprehensive technical data and usage testimonials. Moreover, manufacturers who offer reliable aftersales support and warranty assurances further cement customer confidence. By facilitating direct communication and feedback, these companies create a feedback loop that ensures continuous improvement while maintaining a customer-centric approach. In conclusion, galvanized bar grating epitomizes a blend of experience, expertise, authoritativeness, and trustworthiness, making it an indispensable material for modern industry and construction. Its ability to deliver efficient load-bearing and long-lasting performance while adhering to rigorous standards offers peace of mind to engineers, architects, and project managers alike. As industries continue to evolve and demand more innovative and steadfast materials, galvanized bar grating will undoubtedly play a crucial role in shaping a sustainable and secure future.

Establishing authoritativeness in the galvanized grating industry involves aligning with established standards and certifications. The American National Standards Institute (ANSI) and the National Association of Architectural Metal Manufacturers (NAAMM) have set stringent guidelines for grating production and usage, ensuring each piece meets high-quality criteria. Companies that adhere to these standards earn recognition as leaders in the industry, further solidified by partnerships with construction giants and contributions to iconic projects worldwide. Case studies demonstrate how compliant grating has been pivotal in constructing skyscrapers, stadiums, and bridges, reinforcing its position as a cornerstone material in contemporary architecture. Such authoritative endorsements provide consumers and enterprises with the assurance that the product can meet both regulatory and operational demands effectively. Trustworthiness emerges naturally from a product's proven track record and the transparency of its suppliers. Companies that offer galvanized bar grating often provide extensive documentation on the manufacturing process, quality control measures, and material certifications. This openness allows clients to make informed decisions based on comprehensive technical data and usage testimonials. Moreover, manufacturers who offer reliable aftersales support and warranty assurances further cement customer confidence. By facilitating direct communication and feedback, these companies create a feedback loop that ensures continuous improvement while maintaining a customer-centric approach. In conclusion, galvanized bar grating epitomizes a blend of experience, expertise, authoritativeness, and trustworthiness, making it an indispensable material for modern industry and construction. Its ability to deliver efficient load-bearing and long-lasting performance while adhering to rigorous standards offers peace of mind to engineers, architects, and project managers alike. As industries continue to evolve and demand more innovative and steadfast materials, galvanized bar grating will undoubtedly play a crucial role in shaping a sustainable and secure future.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025