loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 14, 2025 09:37

Back to list

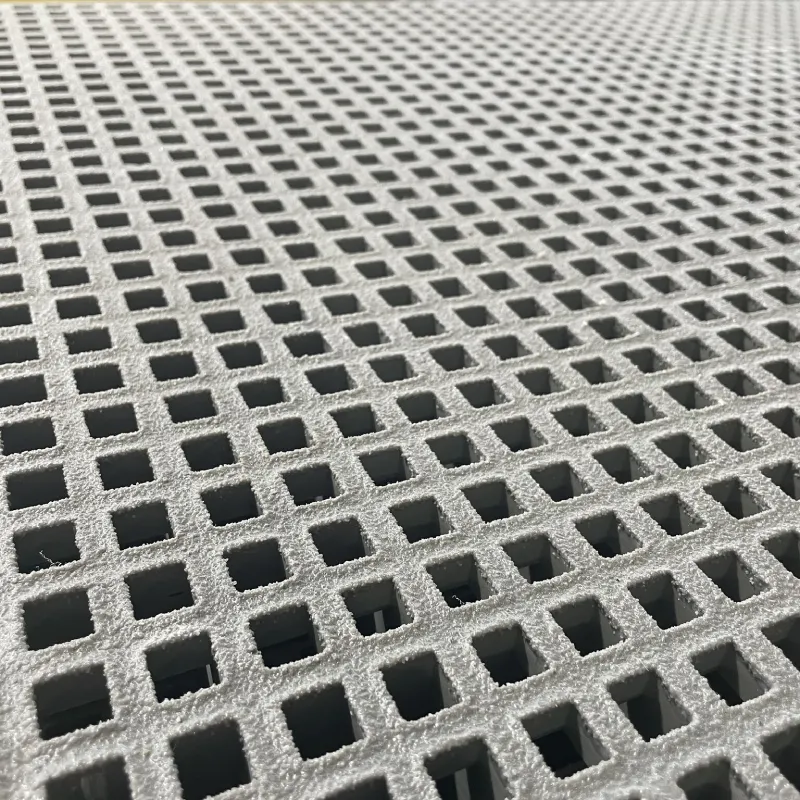

frp grating price

Navigating the landscape of FRP grating prices can be complex, especially when aiming to secure the best value for your project needs. FRP (Fiber Reinforced Plastic) grating has become an essential component in various industries due to its superior durability, corrosion resistance, and lightweight properties. Here’s a comprehensive overview that not only provides insight into current price trends but also empowers you with the knowledge to make informed purchasing decisions.

Geographical location and supplier reputation play pivotal roles in the final pricing structure. Established suppliers with a strong track record often offer better reliability and product quality assurances, which can reflect in a premium price. However, their extensive experience ensures peace of mind in product performance and after-sales support. Additionally, regional variations in raw material costs, shipping expenses, and local economic conditions can influence pricing. Selecting suppliers near your location can reduce logistical costs and lead times. For those focused on budget efficiency, bulk purchasing might offer significant cost advantages, as suppliers usually provide discounts for large volume orders. It's advisable to consolidate your purchasing plans to maximize the benefits of bulk pricing models. To enhance your purchasing strategy, consider utilizing recent advancements in supply chain technologies and digital platforms. These tools facilitate comprehensive market research, allowing you to compare prices from various suppliers efficiently. Utilize online reviews and supplier ratings to gauge market credibility and buyer experiences, thus aligning your purchasing strategy with prevailing market dynamics. In conclusion, obtaining competitive FRP grating prices is not merely about finding the lowest price. It’s about striking a balance between cost, product quality, and supplier trustworthiness. By considering resin type, grating specifications, customization needs, and establishing a relationship with reputable suppliers, buyers are better positioned to achieve optimal results. Knowledge and strategic planning remain your greatest tools in navigating the FRP grating landscape, ensuring both fiscal responsibility and high product performance across applications.

Geographical location and supplier reputation play pivotal roles in the final pricing structure. Established suppliers with a strong track record often offer better reliability and product quality assurances, which can reflect in a premium price. However, their extensive experience ensures peace of mind in product performance and after-sales support. Additionally, regional variations in raw material costs, shipping expenses, and local economic conditions can influence pricing. Selecting suppliers near your location can reduce logistical costs and lead times. For those focused on budget efficiency, bulk purchasing might offer significant cost advantages, as suppliers usually provide discounts for large volume orders. It's advisable to consolidate your purchasing plans to maximize the benefits of bulk pricing models. To enhance your purchasing strategy, consider utilizing recent advancements in supply chain technologies and digital platforms. These tools facilitate comprehensive market research, allowing you to compare prices from various suppliers efficiently. Utilize online reviews and supplier ratings to gauge market credibility and buyer experiences, thus aligning your purchasing strategy with prevailing market dynamics. In conclusion, obtaining competitive FRP grating prices is not merely about finding the lowest price. It’s about striking a balance between cost, product quality, and supplier trustworthiness. By considering resin type, grating specifications, customization needs, and establishing a relationship with reputable suppliers, buyers are better positioned to achieve optimal results. Knowledge and strategic planning remain your greatest tools in navigating the FRP grating landscape, ensuring both fiscal responsibility and high product performance across applications.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025