loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

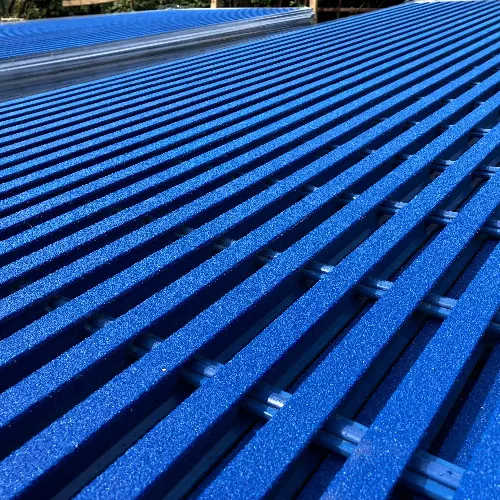

Durable and Lightweight Solutions with Fiberglass Reinforced Plastic Grating for Various Applications

Understanding Fiberglass Reinforced Plastic Grating

Fiberglass Reinforced Plastic (FRP) grating has emerged as a highly valued material in various industrial and commercial applications due to its remarkable strength, durability, and low maintenance requirements. By combining fiberglass with resin, FRP grating offers a lightweight yet robust solution that withstands harsh environmental conditions and heavy loads. This article delves into the properties, benefits, applications, and future prospects of FRP grating.

Properties of FRP Grating

FRP grating is manufactured through a process that combines fiberglass strands and resin, creating a matrix that is both resilient and non-corrosive. The most common resin used in the production of FRP grating is isophthalic polyester or vinyl ester, which enhances the material's resistance to chemicals and UV light. This combination of materials results in a product that has a high strength-to-weight ratio, making it easy to manipulate and install while still capable of supporting significant loads.

The surface of FRP grating can be designed to provide anti-slip properties, ensuring safety in environments where foot traffic and machinery coalesce. Additionally, the material is inherently non-conductive, making it an excellent choice for electrical insulation applications.

Benefits of FRP Grating

The advantages of FRP grating are manifold, contributing to its growing popularity in various sectors. Firstly, its lightweight nature allows for easier transportation and installation compared to traditional materials like steel or aluminum. This not only reduces labor costs but also minimizes the risk of injury during handling.

Secondly, FRP grating boasts impressive corrosion resistance, which is particularly beneficial in environments exposed to chemicals, saltwater, or moisture. As a result, FRP structures have a significantly longer lifespan with lower maintenance needs, leading to cost savings over time.

Furthermore, the installation of FRP grating often requires fewer structural supports, enabling more flexible design options without compromising safety or performance. This adaptability makes it suitable for a wide range of applications, from walkways and platforms to pedestrian bridges and drainage systems.

fiberglass reinforced plastic grating

Applications of FRP Grating

FRP grating finds utility in numerous industries, including chemical processing, wastewater treatment, oil and gas, food processing, and marine applications. In chemical plants, for instance, FRP grating protects personnel from slips and falls while providing a rugged surface that resists chemical spills.

In wastewater treatment facilities, the corrosion-resistant properties of FRP help maintain the integrity of walkways and platforms, allowing for the safe movement of workers. The oil and gas industry benefits from the material's light weight and resilience, using FRP grating in offshore platforms and refineries, where exposure to harsh environments is a given.

Moreover, the food processing sector capitalizes on the ease of cleaning and sanitary properties of FRP grating, which is critical for maintaining hygiene standards in food production areas.

Future Prospects of FRP Grating

The future of fiberglass reinforced plastic grating appears promising as industries increasingly prioritize safety, efficiency, and sustainability. Innovations in manufacturing processes and material formulations may enhance the mechanical properties and environmental resistance of FRP, further expanding its application scope.

Continued research and development will likely lead to cost reductions, making FRP grating even more accessible for smaller projects and businesses that previously considered traditional materials as their only option. The potential for customized designs and incorporation into advanced building systems also highlights the versatility and adaptability of FRP grating in modern construction practices.

In conclusion, fiberglass reinforced plastic grating is a versatile, durable, and cost-effective material that offers significant advantages over traditional materials. Its wide range of applications across various sectors underscores its importance in ensuring safety and efficiency in different environments. As the industry evolves, FRP grating is poised to play an even more critical role in the construction and manufacturing sectors. With its combination of strength, lightweight properties, and chemical resistance, FRP grating is indeed a material for the future.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025