loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

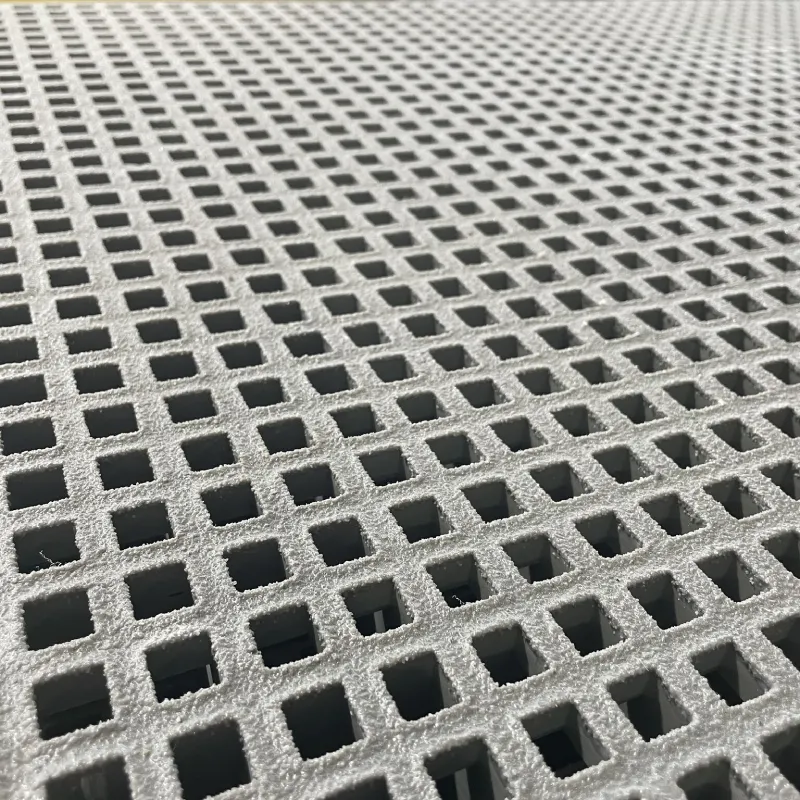

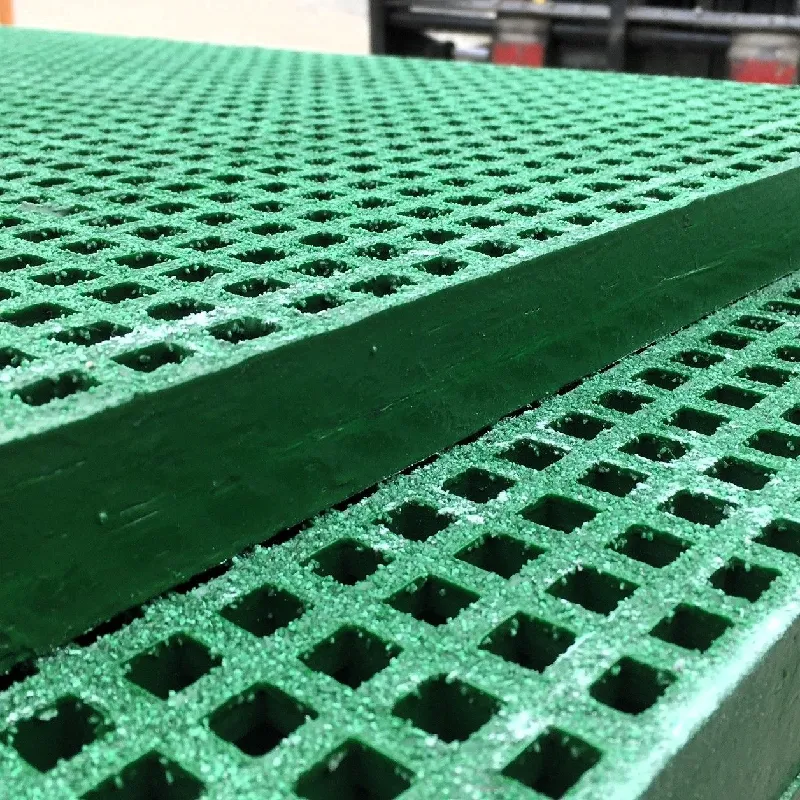

Mini Mesh Grating: Anti-Slip, Corrosion-Proof - Top Choice?

Smaller Open Mesh Area FRP Mini Mesh Grating: what’s really driving the switch

Ports, marinas, and even wastewater plants keep telling me the same thing: when they swap old metal decks for mini mesh grating, the maintenance crews finally breathe. ZJ Composites’ “Smaller Open Mesh Area FRP Mini Mesh Grating,” manufactured in Hengshui, Hebei, China, has been popping up on piers, docks, and ramps because it’s strong, waterproof, and frankly, it just lasts.

Industry trends (and why this matters)

Two big pushes: corrosion resistance and safer pedestrian surfaces. Steel is still great until salt spray or chemicals chew it up. Molded FRP with a mini-mesh profile offers heel-proof openings, better slip resistance, and—surprisingly—light transmission that some coastal permitting teams now prefer for habitat-friendly walkways. Many customers say inspection intervals are stretched out by years; fewer shutdowns, fewer headaches.

Technical snapshot

This is a molded E‑glass fiber + thermoset resin system. Typical resin choices are isophthalic polyester for general use and vinyl ester for aggressive chemicals. Gritted top surfaces push wet friction higher, which, to be honest, is where the real-world safety lives.

| Spec (≈ typical) | Value / Notes |

|---|---|

| Panel thickness | 25–38 mm (common marine: 25 or 38 mm) |

| Mini-mesh aperture | ≈ 12–19 mm square; heel-proof design |

| Open area | ≈ 30–42% (configuration-dependent) |

| Flexural strength | ≈ 150–240 MPa (ASTM D790 lab) |

| Flame spread | ASTM E84, Class 1 (resin and loading may affect) |

| Slip resistance | Wet COF ≈ 0.6–0.8 with gritted top (field may vary) |

| Uniform load at L/200 deflection | ≈ 4–6 kPa @ 600 mm span (lab) |

| Service life | 20–30 years in marine/wastewater with routine washdowns |

How it’s made (short version)

Materials: E-glass roving/mat, isophthalic or vinyl ester resin, UV inhibitor, fire retardant, surface grit.

Methods: Mold prep → fiber placement → resin casting → thermal cure → demold → edge trim → grit application → QC.

Testing: Flexural (ASTM D790), flammability (ASTM E84, ASTM D635), chemical resistance (ASTM D543). Plants typically run ISO 9001 QA, which, I guess, keeps batch variance tight.

Where it’s used

- Marine piers, docks, ramps—ZJ’s base is at No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui.

- Wastewater walkways and clarifier covers (chemical splash zones).

- Food plants and chemical loading bays (dielectric, non-sparking).

- Transit platforms and rooftop access—lightweight and corrosion-proof.

Customization

Panel sizes cut-to-fit, colors (grey, green, yellow), resin systems (ISO poly vs. vinyl ester), gritted or meniscus top, conductive options, edge caps, hold-down clips, and fastener kits. Most buyers ask for pre-drilled hold-downs for faster installs; fair enough.

Vendor snapshot (what I’m seeing in bids)

| Vendor | Core Strength | Fire/QA | Lead Time |

|---|---|---|---|

| ZJ Composites | Marine-focused, strong mini-mesh catalog | ASTM E84 Class 1 options; ISO 9001 factory | ≈ 3–6 weeks, project-dependent |

| Regional Supplier A | Good local stock, limited colors | Basic QA, fire options on request | 1–3 weeks ex-warehouse |

| Import Brand B | Economy pricing, mixed surface grit | Varies by batch; verify certificates | 4–8 weeks ocean freight |

Field notes and short cases

mini mesh grating on a Gulf marina: 320 m of dock decking in vinyl ester, gritted. After 18 months, rust issues were zero (obviously), and the site safety lead told me slip incidents dropped about 30% during wet-weather months. A wastewater plant in Southeast Asia swapped carbon steel for mini mesh grating over aeration tanks; maintenance man-hours fell roughly 25% year-on-year thanks to fewer recoats and no hot-work permits.

Final check-list before you buy

- Confirm span vs. load tables (aim for L/200 deflection or better).

- Specify resin (vinyl ester for harsh chem; ISO poly for general marine).

- Ask for ASTM E84 and D635 reports plus ISO 9001 certificate copies.

- Get pre-fitted clips and edge caps; it speeds install a lot.

References:

- ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials.

- ASTM D790 – Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics.

- ASTM D635 – Standard Test Method for Rate of Burning and/or Extent and Time of Burning of Plastics.

- ASTM D543 – Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents.

- ISO 9001 – Quality Management Systems Requirements.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025