loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

کانوونی دووەم . 26, 2025 04:17

Back to list

reinforced concrete with frp bars mechanics and design

Reinforced concrete with FRP (fiber-reinforced polymer) bars marks a significant advancement in construction material technology, bridging the gap between traditional reinforcement techniques and modern-day engineering requirements. This innovative composition offers a harmonious balance of durability, flexibility, and long-term resilience, setting a new standard in structural engineering.

Expert insights into the design process underscore the importance of leveraging advanced simulation software to predict the behavior of FRP-reinforced structures under various stress conditions. This predictive analysis empowers engineers to foresee potential structural deficiencies and proactively address them in the design phase. Authoritative industry voices advocate for the incorporation of FRP bars as a standard practice in sustainable construction initiatives. The environmental benefits, rooted in the reduced need for repairs and the elimination of steel production emissions, position FRP bars as an eco-friendly alternative in the journey towards net-zero carbon construction. For stakeholders considering this innovative approach, trustworthiness rests on understanding the material characteristics and the proven reliability of FRP bars in real-world applications. Case studies from pioneering projects demonstrate significant improvements in structural longevity and stability, reinforcing the credibility and industry endorsement for these advanced materials. In conclusion, the technological leverage provided by reinforced concrete with FRP bars leads to stronger, more sustainable, and maintenance-efficient structures. The forward momentum in this field relies on ongoing research, rigorous testing, and continuous dialogue among civil engineers, architects, and material scientists, ensuring this innovation meets the ever-evolving demands of modern infrastructure.

Expert insights into the design process underscore the importance of leveraging advanced simulation software to predict the behavior of FRP-reinforced structures under various stress conditions. This predictive analysis empowers engineers to foresee potential structural deficiencies and proactively address them in the design phase. Authoritative industry voices advocate for the incorporation of FRP bars as a standard practice in sustainable construction initiatives. The environmental benefits, rooted in the reduced need for repairs and the elimination of steel production emissions, position FRP bars as an eco-friendly alternative in the journey towards net-zero carbon construction. For stakeholders considering this innovative approach, trustworthiness rests on understanding the material characteristics and the proven reliability of FRP bars in real-world applications. Case studies from pioneering projects demonstrate significant improvements in structural longevity and stability, reinforcing the credibility and industry endorsement for these advanced materials. In conclusion, the technological leverage provided by reinforced concrete with FRP bars leads to stronger, more sustainable, and maintenance-efficient structures. The forward momentum in this field relies on ongoing research, rigorous testing, and continuous dialogue among civil engineers, architects, and material scientists, ensuring this innovation meets the ever-evolving demands of modern infrastructure.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

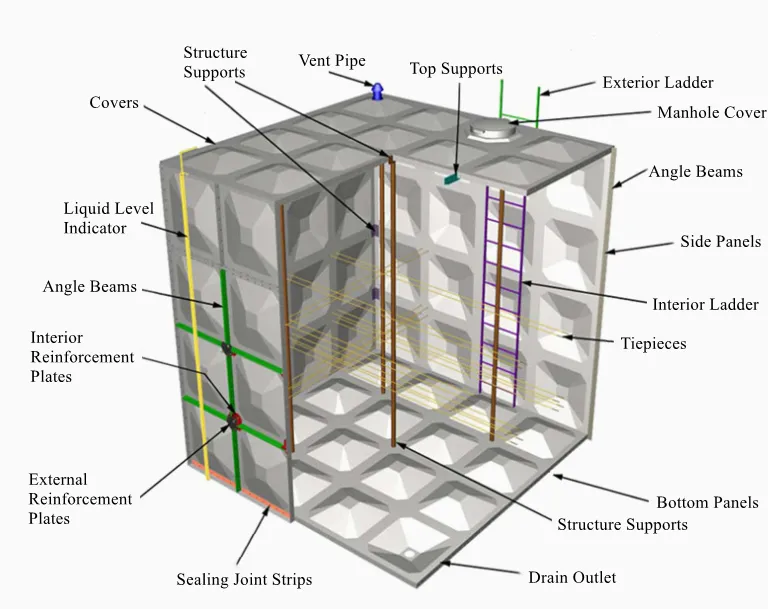

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025